Scrubber Pumps Article

Scrubbers are used in industrial and marine processes in order to reduce the level of harmful emissions being emitted into the environment. The design is similar to the way AdBlue is used in a car with a liquid being sprayed onto emissions to capture and neutralize harmful gas particles. There are four different types of scrubber which are open loop, closed loop/hybrid, wet scrubber and dry scrubber.

The types of liquids used to neutralize gases include lime milk, caustic soda, magnesium hydroxide and seawater.

Types of scrubber types in which pumps are used include:

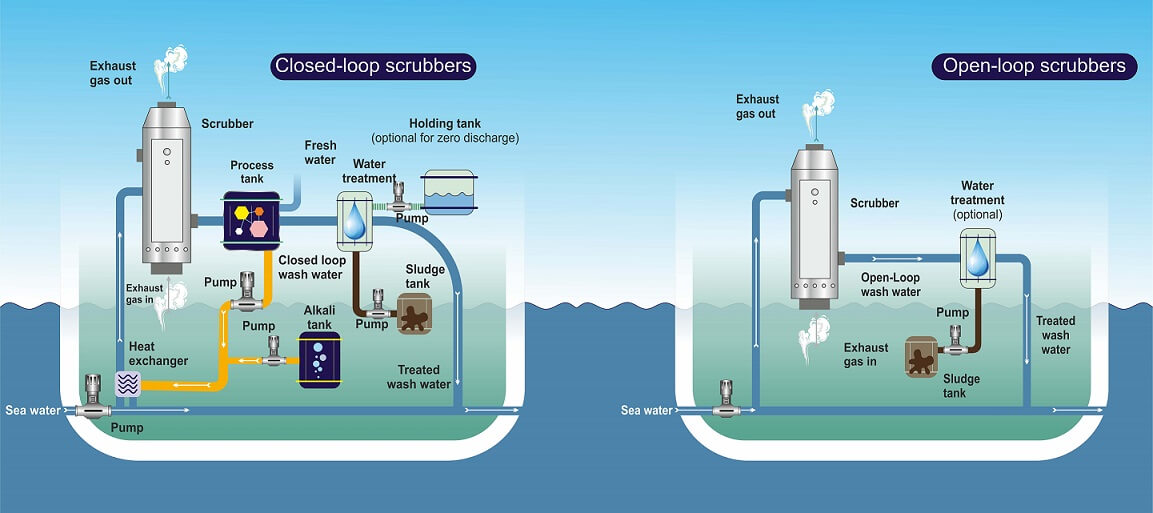

Open Loop - This system operates with seawater being sprayed onto exhaust gases which reacts with the emissions creating sulphuric acid which is neutralised by the natural alkalinity of the seawater. The wastewater is treated then discharged overboard.

Closed Loop - A closed-loop scrubber system operates with seawater mixed with caustic soda sprayed onto emissions. All contaminants captured separately in holding tanks and only a small amount of effluent discharge, with the holding tanks discharged at the port.

Hybrid - Such scrubbers can switch between open and closed-loop mode as some ports do not allow open-loop systems meaning the system switches to closed-loop mode at these ports but when at sea can switch to open loop.

Wet Scrubber – Wet scrubbers remove dust particles via the use of liquid droplets.

Dry Scrubber – Dry scrubbers use dry powders and chemicals to treat emissions.

View our Scrubber Pump range here

The image below shows an exploded view of Open and Closed Loop Scrubber installation.