Fuel Overview: Pumping Fuel

Typical Viscosity: up to 1500cst

Typical SG: 0.95 to 1.03

The term "fuel” refers to a substance that can be burned or undergo a chemical reaction to generate energy. Essentially, it serves as a stored energy source.

Fuel pumps are referred to liquids primarily used in transportation, including petrol, diesel, heavy fuel oil, LPG, and kerosene. However, with recent technological advancements and initiatives to reduce carbon emissions, this category now extends to liquids such as liquid hydrogen, methanol, LNG, and biofuels.

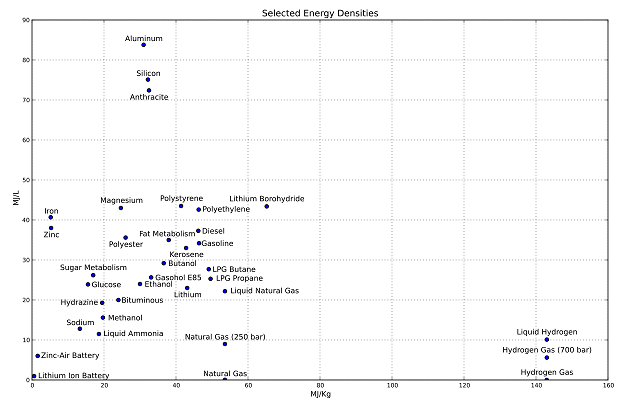

The below table details the energy that can be stored within a given mass within various different types of fuels known as energy density measured in Megajoules per Kg.

View our range of fuel pumps or see how we help the Fuels & Petroleum Industry

Image by By Scott Dial - Own workData Source: Energy density, Lithium-ion battery, Public Domain, https://commons.wikimedia.org/w/index.php?curid=5551431

What to consider when selecting a pump for fuel transfer

When searching for a fuel pump, a number of factors need to be considered in order to ensure optimal performance, efficiency, and compatibility, such as;

Type of Fuel: Identify the type of fuel your system operates on—gasoline, diesel, or alternative fuels like ethanol. The fuel type dictates the pump's design, materials, and compatibility, ensuring it can handle the specific fuel properties without corrosion or malfunction. The viscosity can also affect the pump selected and power used by the pump.

Flow Rate: Determine the required flow rate of the fuel pump. Your optimal flow rate will depend on the size of the tank you are storing fuel in, and how quickly you need it emptied or refilled. When calculating your flow rate, you should factor in the process steps either side of the tank. This will help you identify where bottlenecks could occur if the flow rate has been inaccurately calculated.

Pressure Rating: Consider the operating pressure requirements of your fuel process and choose a fuel pump that is capable of maintaining the necessary pressure consistently. Factors such as viscosity and any possible fluctuations in this need to be carefully considered. The distance being pumped also has a huge impact on the pressure required, and if the process covers a large distance, the viscosity may impact the pressure losses and dictate what pressure can be achieved.

Voltage & Frequency Compatibility: Ensure the fuel pump's voltage and frequency rating is suitable for the geographical location it will be used in. Using a pump with an incorrect voltage rating can lead to electrical issues, reduced performance, or even damage to the pump or electrical components.

Mounting and Installation: Evaluate the pump's size, shape, and mounting options to ensure compatibility with your process design. . Consider factors such as space constraints, mounting orientation, and accessibility for installation and maintenance. If the pump is required to strip tanks then the orientation and mounting of the pump needs to be suitable for the tanks used in the process and may require additional controls to ensure the pump does not dry run.

Durability and Reliability: Opt for a fuel pump constructed from high-quality materials that offer durability and resistance to corrosion, abrasion, and chemical degradation. A reliable pump ensures consistent fuel delivery and minimizes the risk of breakdowns or failures. Ductile iron is more resistant to high pressures, whilst grey cast iron is often more economical however it is brittle and prone to breakage upon impact.

Noise Level: Assess the noise level produced by the fuel pump during operation, particularly if noise is a concern in your application.

Some pumps can be located in installations where a backup generator is required such as hospitals and as such a pump operating at high speeds with a low viscosity fuel can be noisy.

Choose a pump where consideration has been given to the fuel viscosity, speed of operation and noise produced. Alternatively, aftermarket solutions such as soundproof enclosures can be selected if quieter operation is desired.

For more information about how we can help you specify, select or maintain a pump for fuel get in touch with our team of pump sales engineers.