What are Heating Jackets?

What are heating jackets and why might they be fitted to pumps?

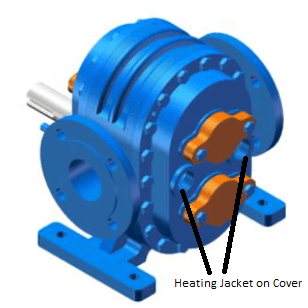

Pumps can be fitted with heating jackets as a way of ensuring any liquid pumped maintains a set temperature which may be critical to an application. They can also be used to ensure the product does not solidify within a pump in particular in and around seals, valves, and any other moving parts which could shorten life span by accelerating wear. Some liquids require heating to reduce their viscosity making the liquid easier to pump and flow ensuring pump conditions remain optimal.

Example applications in which heating jackets are often used include Bitumen, Heavy Fuel Oil (HFO). The liquids which are used for transferring heat to pumps and pipework include steam, oil and electricity through trace heating. When a liquid is used on a pump casing the heating element can either be single meaning one side of the casing or double meaning both sides of the pump casing.

A pump mounted pressure relief valve can not be used with particular fluids which solidify when cooled such as chocolate and bitumen as should product cool and harden within the valve, it can eliminate the effectiveness of the valve by forming a plug rendering the valve useless. The hardened product can also contaminate fresh new batches of the product being pumped leading to contaminated batches.

If you have a requirement for a pump with a heating jacket, with either internal or external mounted relief valve contact us to ensure the correct selection is made for your process.