Flexible Impeller Pump Troubleshooting Guide

Flexible Impeller Troubleshooting Guide

If you are experiencing issues with your Flexible Impeller Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers:

If you are experiencing issues with your Flexible Impeller Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers:

Problem | Possible Cause | Remedy |

Pump is not drawing in liquid (priming) | Suction pipework is not airtight | Remake any joints, ideally with sealant and not PTFE tape |

Suction Line is blocked or valve shut | Clear suction line and any valves | |

Impeller Damaged or worn | Replace Impeller | |

Discharge Line blocked or valve closed | Clean fittings and pipework on discharge line | |

Pump Pressure is Low | Impeller is worn or wear plate damaged | Check impeller for wear, cracks, tear, or chemical attack |

Fluid Viscosity too High | Check fluid viscosity in line with original specification | |

Pump Running Too Fast | Pump Speed May be too high for viscosity of Fluid | |

Pump Leaking | Mechanical Seal Defective, or O Ring worn | Check Mechanical Seals and O Rings and Replace where needed |

Pump is not Operational | Impeller Stuck | Flush pump with pumped medium to loosen impeller |

Impeller Clogged or swollen | Remove any solids, check impeller for chemical attack. Check impeller material against chemical to ensure compatible. Check liquid Manufacturer has not changed the additives or components of the fluid. | |

Dry Run Protection Activated | Reset. Check pump operating conditions | |

Motor not Rotating | Have motor windings, and resistance checked by qualified engineer. |

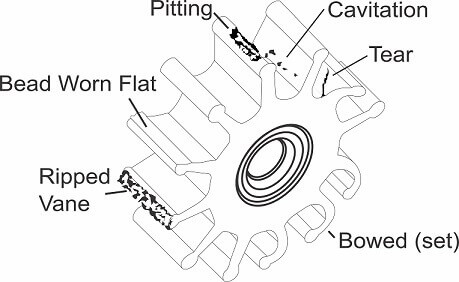

Signs of Flexible Impeller Vane Damage:

Need spare parts or replacement Pump? Order online