Peristaltic Pump Troubleshooting Guide

Peristaltic Pump Troubleshooting Guide

If you are experiencing issues with your Peristaltic Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers:

If you are experiencing issues with your Peristaltic Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers:

Problem | Possible Cause | Remedy |

Pump does not Start | Insufficient Motor Power / Performance | Check Motor Rating, Power, that motor is running operationally sound independently of pump, Winding resistance. Repair/Replace if necessary |

Insufficient output from Frequency Converter | Check Frequency converter matches motor | |

Pump Blockage | Check Voltage and current draw. Pump Start occurs at 10Hz | |

Pump Blockage | Check if pump suction or discharge is blocked | |

| Valves on discharge and/ or suction may be closed fully or partially | Open Valves fully |

Pump Hose Compression too little | Check number of shims fitted on rollers is correct for pump model | |

Hose Rupture / Leakage | Replace Hose | |

Partial Blockage | Clear Suction and Delivery lines | |

Insufficient Inlet Pressure | Increase level of fluid in suction tank, replace pump, or reduce pump speed | |

Inlet Pipework too Small | Increase Suction Pipe Diameter | |

Suction Line too Long | Ensure Suction line is as short as Possible | |

Viscosity of Fluid | Check it is in line with original specification. Viscosity may change with temperature. | |

Suction of Air | Ensure Connections are airtight | |

Pulsating Suction Line | Ensure all connections are tight. Use pulsation dampeners to reduce pulsations by up to 98%. Check Application | |

High Pump Temperature | Hose not lubricated | Lubricate Pump Hose |

Product Temperature High | Reduce Fluid Temperature | |

Poor Suction Conditions or Insufficient Suction | Check Suction Line for Blockages | |

Pump Speed too High | Reduce Pump Speed | |

Vibration on Pump & Pipework | Connecting Pipework not fastened Correctly | Ensure pipework is connected with accessories such as brackets where required |

Pump Speed too High | Reduce Pump Speed | |

Insufficient Pipe Bore | Increase bore of pipe | |

Pump Loose on Baseplate | Tighten Baseplate | |

Pulsation Dampeners insufficient or missing | Install pulsation dampeners on Suction & Discharge | |

Short Hose Life | Chemical Attack | Check Hose Chemical Compatibility with liquid pumped, any cleaning agents used and lubricant |

High Pump Speed | Reduce Pump Speed | |

High Temperature | Reduce fluid Temperature | |

High Operating Pressure | Reduce Operating Pressure | |

Cavitation | Check Suction Conditions including bore of pipe, tank size, viscosity of fluid with pump capacity | |

Elevated Temperature | Check Rollers Shaft Mounting | |

Unsuitable Lubricant | Only use Lubricant from North Ridge Pumps | |

Insufficient Grease | Top Up Lubricant | |

Pump Hose Pulled into Housing | High Inlet Pressure >3 Bar | Reduce inlet Pressure |

Pump Hose contains Deposits | Clean or Replace Pump Hose | |

Holder (press flange) not Tight | Re-tighten Press Flange and Holder | |

Insufficient Grease | Top Up Lubricant |

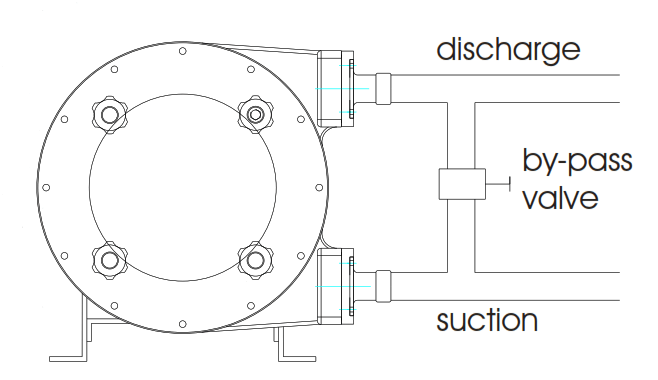

See below suggested installation for a peristaltic pump within a CIP Process:

A by-pass valve is required in this situation as per the below piping schematic.