AOD Pump Troubleshooting Guide

AOD Pump Troubleshooting Guide

If you are experiencing issues with your AOD Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers for further assistance:

If you are experiencing issues with your AOD Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers for further assistance:

Problem | Possible Cause | Remedy |

Pump Does not Start | Lack of Air | Check air circuit, valves and connections |

Insufficient Air Pressure | Adjust Pressure. Check consumption of pump against other devices on the same air line | |

Insufficient Air Flow Rate | Check piping size, connections, and consumptions against other devices on the same air line | |

Damaged Control Valve | Check and replace if necessary | |

Pump intake or Delivery Closed | Disconnect Suction and Delivery hoses and see if pump starts | |

Pneumatic Exchanger Damaged / Broken | Replace exchanger. Check for presence of ice in air discharge. Clear ice and retry | |

Broken Diaphragm | Check for air leaking through pump discharge pipe | |

Pump Stalled | Reset Pump by following commissioning procedure to check inlet and outlet pipework, installation of the valves and three-way valves | |

Pump not Delivering Fluid | Balls Not Seating | Disassemble manifolds, clean seats or replace balls and seats |

Suction too high | Reduce Suction Height | |

Viscosity of Fluid too high | Increase pipe diameter on intake. Decrease pump cycles. The diaphragms on a pump are like a pair of lungs. By working too quickly with viscous fluids they do not fill and consequently deliver fluid | |

Suction Blocked | Check and remove blockage | |

Pump Cycles Slow | Fluid is Too viscous | Increase pump size, increase pipe diameter |

Suction / Delivery hose blocked | Check and clean | |

Pump Operation is erratic | Pneumatic Air Valve is worn | Replace |

Shaft is worn | Replace | |

Ice on discharge | Check all air control devices and any snap on couplings | |

Internal Exchanger Fouled | Clean | |

Pump Stalls | Intake Blocked | Check hose does not kink. Clear blockage. Replace if necessary |

Air dirty or contaminated with oil or condensation | Check pressure using pressure gauge on pump during operation. If pressure is low compared to supply pressure recheck all fittings. In 90% of cases all stalls are caused by snap on fittings | |

Faulty Distributor | Replace | |

Correct stopping procedure to pump not applied | Ensure correct pump stopping procedure is followed | |

Low Pump Flow Rate | Intake hose not connected correctly | Check |

Blocked Pipe | Check and clean | |

Fluid is too viscous | Install larger diameter pipes, run pump slower, increase pump size | |

Balls Not Seating | Disassemble manifolds and clean seats and balls | |

Insufficient Air Flow | Check pressure using pressure gauge on pump during operation. If pressure is low compared to supply pressure recheck all fittings. In 90% of cases all stalls are caused by snap on fittings |

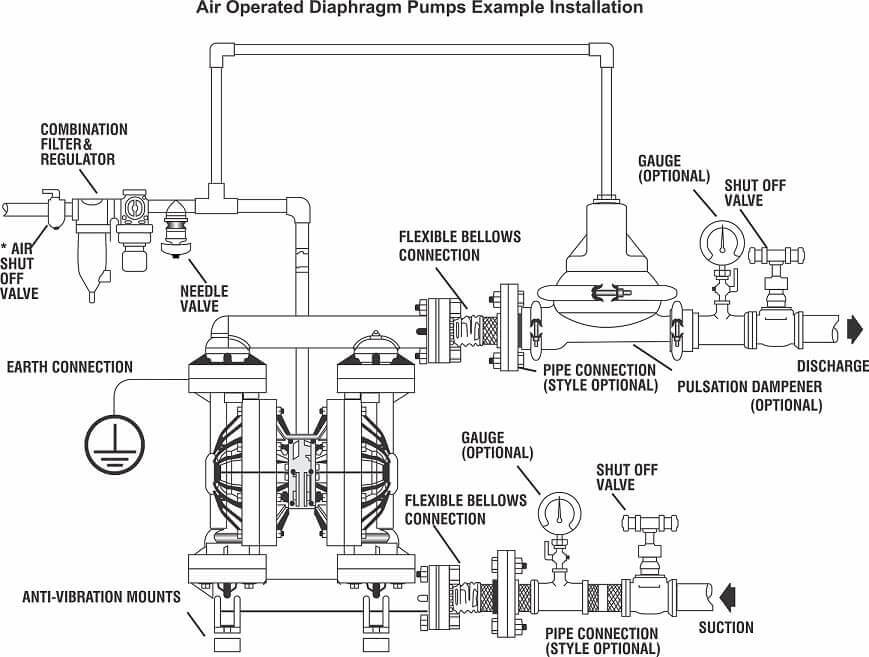

See below our example AOD Pump installation:

Examples of Damaged or Worn Pumps

(1000 x 350 px) (1)-24070513042250312.png)