Side Channel Pump Troubleshooting Guide

Side Channel Pump Troubleshooting Guide

If you are experiencing issues with your Side Channel Pump, the below guide can help you diagnose any issues, or speak to one of our Technical Sales Engineers for further assistance:

Problem | Possible Cause | Remedy |

Delivery Rate too Low | Back pressure too high | Check duty point against curve |

Suction Head too high, or supply pressure too low | Check liquid level. Open all valves on discharge | |

Blocked Filter. NPSH incorrect | Clean filters, and check suction pipework | |

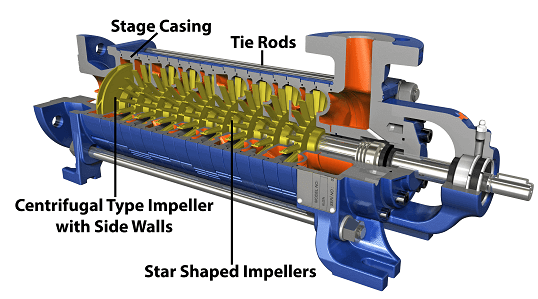

Suction of air through pump shaft seal and stage casing seals | Replace any worn seals, gaskets, and O rings. Check shaft diameter for wear | |

Incorrect Rotation | Check direction of rotation | |

Air ingress through housing or suction line | Replace housing seal, and check flange gasket sealing. Check suction tank for signs of vortexing. | |

Pump not Priming | Suction of air through pump shaft seal and stage casing seals | Replace any worn seals, gaskets, and o rings. Check shaft diameter for wear |

Air ingress through housing or suction line | Replace housing seal, and check flange gasket sealing | |

Priming requirements too high | Check liquid level, and depth of suction pipe | |

Incorrect Rotation | Check direction of rotation | |

Pump not filled with fluid | Fill pump with fluid | |

Suction or discharge valve closed | Open all valves | |

Pipe connections not made correctly | Check all pipe connections | |

Electrical Connections | Check motor, absorbed power, winding resistance, phases | |

Check NPSH in line with pump curve | ||

Screw Plugs in place | Remove screw plugs | |

Pump Leaking | Housing Screw Joints leaking | Check torque of housing screw joints and ensure match figures in manual |

Misalignment | Check alignment and connections are stress free | |

Worn Seals | Replace Seals | |

Temperature Increase in Pump | Pump or Pipe not filled completely | Bleed pump and fill pump, suction and supply lines |

Suction Head too high, or supply pressure too low | Check liquid level. Open all valves on discharge | |

Pump Dry running | Clean filters, and any dirt traps on suction side | |

Pump Noisy or Erratic | Priming requirements excessive, pump cavitating | Check liquid level, depth of suction pipe. Open all valves |

Pump operating below minimum safe continuous flow | Clean all filters and suction pipe. Increase tank level. Check pump Impeller and seals for wear. | |

Pump cavitating | Check supply pressure, and temperature of liquid | |

Excessive torque through magnetic coupling causing disconnection from drive | Check pump for blockage. Check internal sleeve bearings, all operating conditions and density of pumped liquid | |

Misalignment | Check pump setup. Check Coupling for wear and check alignment | |

Particles within pump | Check filter size and system operation | |

Motor operating on 2 phases | Check all electrical connections | |

Antifriction bearing worn | Check when NPSHR meets NPSHA pump operates smoothly | |

Motor protection switch tripped | Solids in Pump | Check pump, filters. Dismantle and clean pump |

Discharge Valve Closed | Open Valve | |

NPSH | Ensure NPSHA meets NPSHR | |

Power consumption too high | Check motor protection switch and all electrical connections | |

Internal Friction | Pump blocked by particles. Shaft bearing worn, motor bearing worn, stuffing box bolted too tight. Check viscosity of fluid. | |

No Fluid Delivery but Motor Operational | Excessive torque through magnetic coupling causing disconnection from drive | Check pump for blockage. Check internal sleeve bearings, all operating conditions and density of pumped liquid |