Hand Pump Guide

Hand pumps are available in a variety of different types and designs but what factors should be considered during selection?

Types

There are various types of hand pumps available and the selection of which will usually depend on the application and liquid being pumped. A brief comparison table below highlights differences in types:

A pumps action and fluid delivery vary depending on not only the movement by the user but the pumping action used to drive the pump.

Rotary Action – Handle rotates in a 360° motion

Rotary Action – Handle rotates in a 360° motion

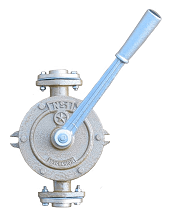

Semi Rotary – Handle rotates in 180° back and forth motion

Single Acting – Fluid is drawn in with forward motion and fluid delivered on backstroke

Double Acting – Fluid is simultaneously drawn in on both forward and backstroke.

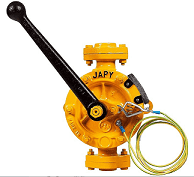

Materials

Hand pumps are available in a variety of materials from polypropylene (pp), PVDF, cast iron, bronze to stainless steel depending on the application. Typically for chemicals, a PP or PVDF material will be selected and for fuels a cast iron or bronze unit with earthing wires. For flammable chemicals, any pump used will have to be earthed and also ensure the body is conductive which is a feature of most metals but plastics must have the material carbon impregnated to ensure a build-up of static does not occur.

Assembly

Assembly

As with most equipment, there are often large differences in cost of hand pumps which attention should be paid close to. Cheaper models are often self-assembly plastic types where the suction tube is screwed together using PTFE tape. There are usually 2 or 3 joints to the body which if not airtight will limit the ability to draw fluid from the bottom of a container. The PTFE tape is subject to wear, and if drawn into the pump can cause the pump to be clogged and for the handle to shear off as the internals stop revolving. Such parts are also prone to loosening. Better designed models have single-piece riser tubes which are a more robust solution.

Mounting

Hand pumps are versatile to mount in a number of ways. Their suction lift capacity means they can be located away from fluids and not only on top of the drum but also on an adjacent wall or floor – especially if a diaphragm pump is selected.

The best practice is always to have the unit as close to the fluid as possible, but if this is not possible a diaphragm or piston pump may be a better solution due to the valves within the pump creating a seal meaning air is ejected and they have the better suction capability.

Usually, hand pumps are chosen due to the lack of power available, for small flow rates in applications such as sampling, for priming a main pump or for emergency use. An alternative can be a cordless battery-powered pump which delivers higher flow rates where multiple batteries can be utilised to ensure a consistent supply of power. Batteries of lithium-ion technology mean charge is not lost if unused for long periods.

Technology

Technology

Hand pumps internal parts are altered to accommodate differing fluid types, viscosities and solids. With differing technologies and fluids depending on the design chosen, pumps will be capable of producing different flows, and pressures. Centrifugal types are common for clean, low viscosity fluids which can produce high flows and relatively low pressures, whereas positive displacement types such as piston and diaphragm pumps have great suction capabilities, can handle viscous fluids but develop much higher pressures but at the sacrifice of flow rates.

If you require a hand pump selecting for an application, consult with us to help us select the correct solution for you.