Air Operated Double Diaphragm Pumps Guide

What is an air operated diaphragm pump?

An Air Operated Double Diaphragm pump is a pump driven by air. Each side of the pump houses two separate diaphragms operating individually, which fill with fluid before being discharged through an outlet manifold. Air Operated Double Diaphragm Pumps are often abbreviated to AODD, AOD, or shortened to Diaphragm Pump. Diaphragm pumps are a positive displacement pump.

How does an air operated diaphragm pump work?

This design is primarily driven by an air valve located within the pumps central chamber. Air enters the valve and is directed to one side of the diaphragm creating a vacuum on one side and compressing the diaphragm on the other.

A diaphragm pumps main parts are its suction and delivery manifolds, diaphragms, central air valve, and balls and seats which operate like valves within the pump. North Ridge Pumps have optimised their design of AOD Pumps to consolidate the number of parts within each pump to a handful, where many older generations of pumps continue to use over 50 parts making maintenance difficult.

Their working principle is when a vacuum is created in one diaphragm it causes the balls on the suction side to rise from their seats, allowing fluid to enter the diaphragm, whilst simultaneously causing the balls located close to the discharge manifold to seal against their seats. In the opposing diaphragm which is compressed, fluid pushes the balls against the seats close to the suction manifold, the balls on the discharge manifold no longer seal the outlet meaning fluid expels through the discharge manifold. This cycle repeats continuously. See our air operated diaphragm pump working animation

Miniature Air Operated Diaphragm Pumps work differently, due to the addition of springs in between balls and seats, enabling the balls to return to their position regardless of orientation, whereas traditional designs rely on gravity.

Such equipment can only be regulated by the volume of air and pressure of air into the inlet valve. Each diaphragm can be likened to a pair of lungs meaning depending on the fluid and viscosity, in order for a pump to operate effectively it must operate at the correct speed. When an AOD pump operates too fast, each diaphragm does not fill fully, reducing efficiency, output and pressure. This is most common with viscous fluids such as waste oils, and sludges.

Air operated diaphragm pump advantages

Such pumps due to their working principle have many advantages which are:

- Dry Running - meaning they will not suffer damage if left operating without fluid

- Self Priming – As they are a positive displacement, and capable of dry running, they can prime up to 8M without issue

- Safe Design – As pumps are air driven they are inherently safe within ATEX environments. Designs are available with carbon impregnation making pumps conductive and suitable for the most volatile atmospheres. Should a discharge valve line be closed the pump will continue to build pressure in the outlet until it matches the inlet pressure. At which point the pump stops, and restarts when outlet pressure reduced.

- Versatile – Due to its simple design, such pumps are available in a wide variety of plastics, and metals ensuring suitability for a wide range of fluids from water, oil, waste oil, diesel, acids, foods, and slurry. They can be easily controlled to accommodate high viscosities without risk of failure. Furthermore, pumps can easily be stripped. Various designs are available from miniature air operated diaphragm pumps which can be mounted in any position within machines, to 4” diaphragm pumps.

- Low shear – due to the speed control available, AOD pumps are low shear and suitable for handling shear sensitive fluids such as foods, Latex, inks and polymers.

They can be installed in a large number of scenarios from immersed, to container emptying, under positive suction, for the pumping and mixing of fluids simultaneously such as Part A and Part B glues, paints, fixatives and bonding agents either separately or mixing together.

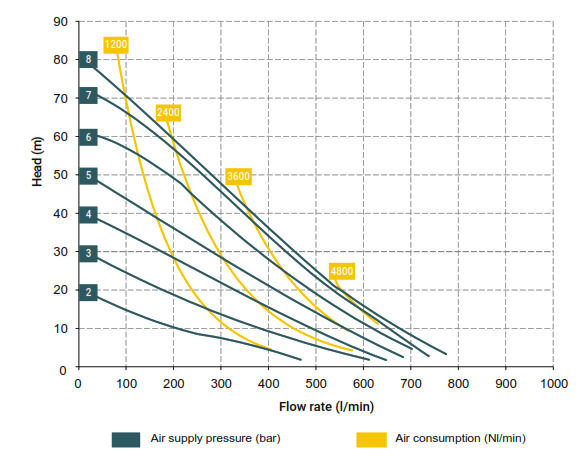

Air operated double diaphragm pump curve

A typical curve shape is similar to centrifugal pump curve with the highest point being on left indicating highest pressure, and lowest flow increasing as the line moves across the axis. A diaphragm pump curve will typically indicate air supply pressure, and air volume required in order to enable the pump to perform as indicated. All curves are based on water, with flooded suction and open outlet, so checks should be made between curve assumptions and expected application.

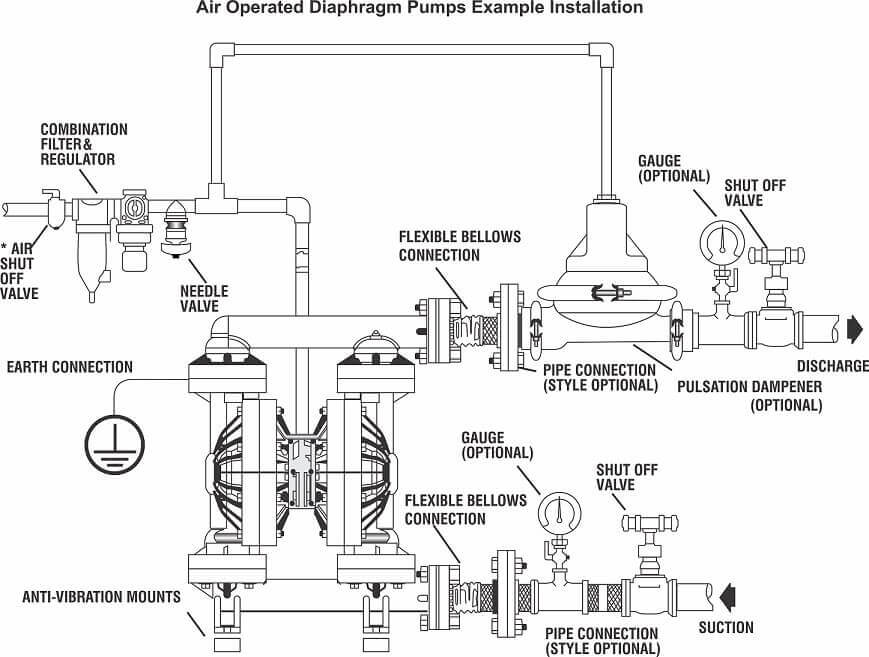

Air operated diaphragm pump installation

Ideally an air operated diaphragm pump should be installed according to the below guidelines. The air supply should pass through a master air valve with regulator fitted. Checks should be made as to whether clean air or lubricated air is required.

North Ridge Pumps utilise clean air, making our pumps suitable for hygienic applications as no oils, or dust are discharged via the exhaust causing contamination.

The pump should be grounded if required, and on the discharge a pressure gauge should be installed monitoring the discharge pressure. In systems where there is not an open-ended discharge a relief line should be installed with pressure relief valve back to the source tank.

Flexible connections on the inlet and outlet of the pump will dampen vibrations and the addition of a pulsation dampener will reduce pulsations by up to 98%

Air operated diaphragm pump applications

Typically AOD pumps can be installed according to the following application scenarios:

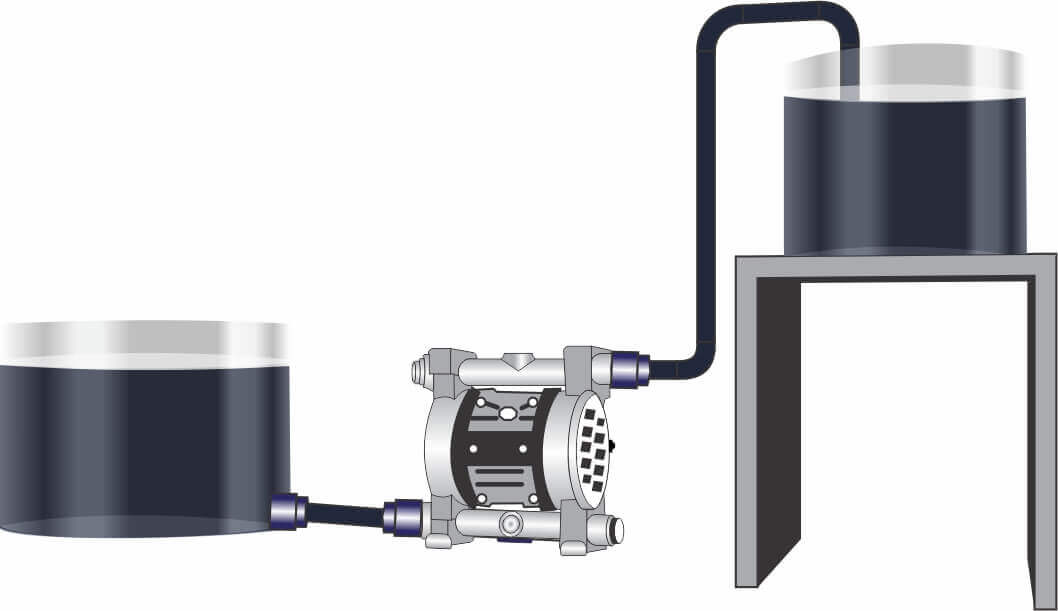

Self Priming – Pump located above tank drawing fluid

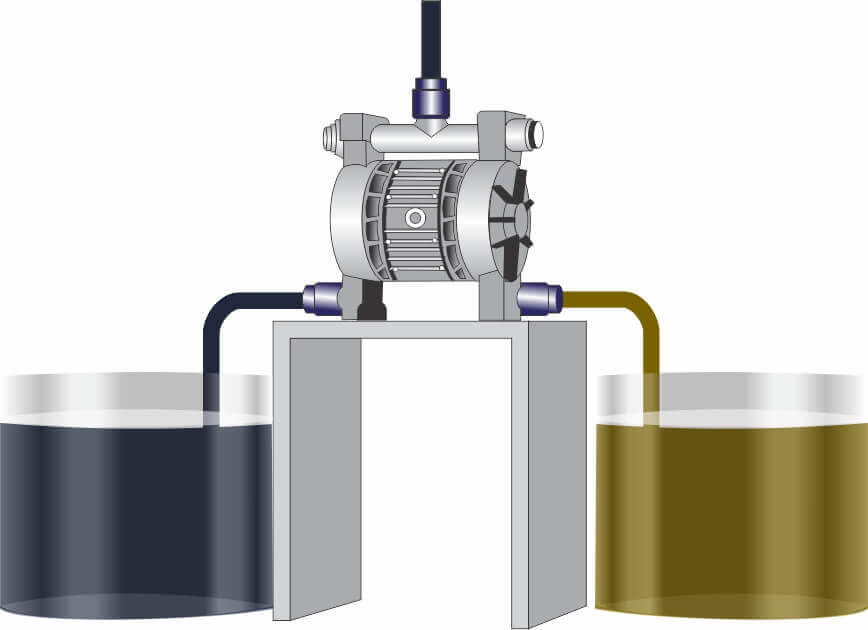

Twin suction and delivery of separate fluids – Manifold is specified with twin inlet and outlet manifold keeping fluids sperate

Twin suction manifold – Pump Is specified with twin inlet manifold but single discharge meaning fluids are mixed at the discharge of the pump

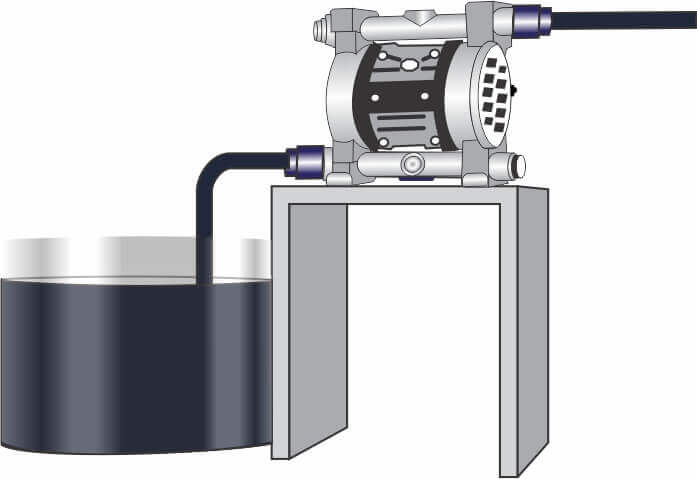

Positive suction – Pump has pressurised inlet

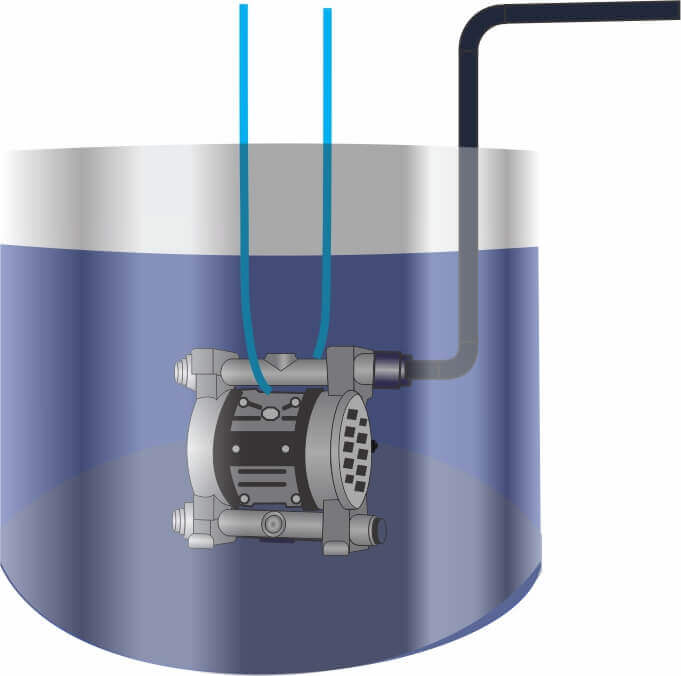

Immersed – Pump is submerged in fluid, with hose connected to exhaust enabling discharge of pressurised air

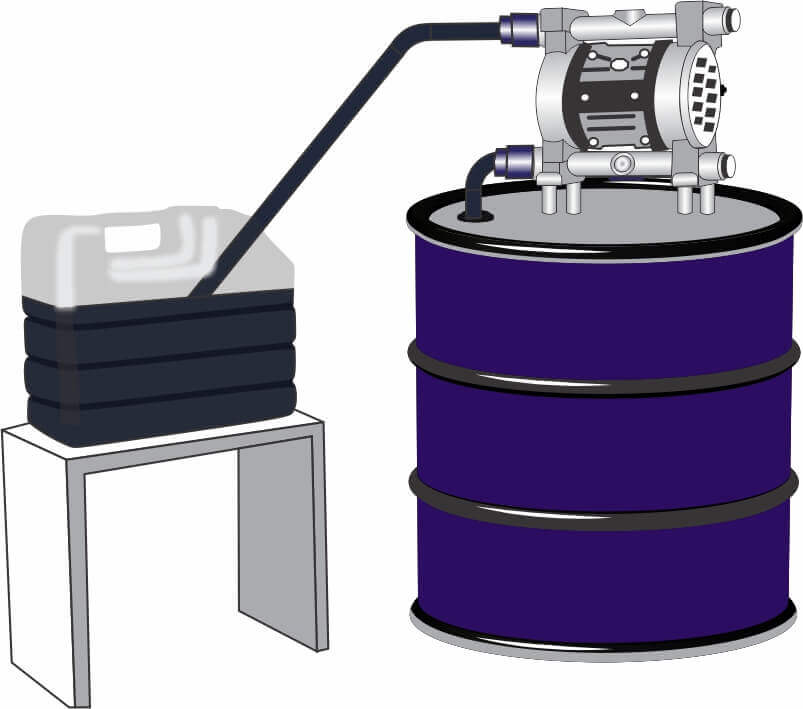

Container Emptying - Emptying of containers from above

Container Emptying - Emptying of containers from above

AOD vs other Types of Pumps

AOD Vs Gear Pump | |

AOD | Gear |

Dry Run without damage | Can not be ran dry |

Handle Abrasives | Can not handle abrasives |

Designed for varying flow, viscosity and head conditions | Limited ability to handle varying viscosity, thixotropic or non Newtonian liquids |

Pump pauses during zero flow without energy consumption at dead head. Restarts once closed valve opens | Relief valve required if deadheaded with only limited time for using bypass |

No rotating or close wear parts which once wear experience large drops in flow | Many Rotating and close tolerance wetted parts |

AOD vs Lobe Pump | |

AOD | Lobe |

Self Priming up to 7.6M | Limited suction |

No rotating or close wear parts which once wear experience large drops in flow | Many Rotating and close tolerance wetted parts |

Pump pauses during zero flow without energy consumption at dead head. Restarts once closed valve opens | Relief valve required if deadheaded with only limited time for using bypass |

Handle Abrasives | Can not handle abrasives |

Handles solids as large as inlet | Limited solids handling |

AOD Vs Progressing Cavity Pump | |

AOD | Progressing Cavity |

Dry run without damage | Can not dry run |

Fewer less expensive wetted wearing parts | Expensive rotating and close tolerance parts |

Maintenance relatively easy | Maintenance time consuming, labour intensive. Usually required to be taken off site for repair as specialist tools and knowledge required for maintenance. |

Virtually no slip with thin liquids such as water | Slip increases with low viscosity fluids |

Pump pauses during zero flow without energy consumption at dead head. Restarts once closed valve opens | Relief valve required if deadheaded with only limited time for using bypass |

Compact design | Larger unit with gearbox |

Handle a wide range of temperatures | Limited temperature handling capability |

AOD vs Vane Pump | |

AOD | Vane Pump |

Dry run without damage | Limited dry run |

Fewer less expensive wetted wearing parts | More rotating and close tolerance parts |

Pump pauses during zero flow without energy consumption at dead head. Restarts once closed valve opens | Relief valve required if deadheaded with only limited time for using bypass |

Handles solids as large as inlet | Limited solids handling |

Handle Abrasives | Can not handle abrasives |

Typical AOD Pump Installation Example

Having difficulty with your AOD pump? View our AOD Troubleshooting Guide

FAQS

They are also controlled by the system in which they are installed in, and if pumped against a dead head, or closed valve they will pause before restarting automatically when a process is restarted.

Their efficiency can be up to 97%, and there are few places for transmission losses to occur as the air valve within the pump directly drives a piston into each diaphragm.

As models vary greatly yet look similar the efficiency of specific models should be studied when making comparisons. From our own tests our 1” model consumed 420 Nominal Litres a minute of air (nl/min) at a particular duty point against 672nL/min of that of a competitor - which in real terms means a competitors model used 60% more air than our model to deliver the same performance.

Often more than one material is suitable for your fluid and selection could be based on the application type. For instance; NBR, Santoprene, EPDM, Hytrel and PTFE are all suitable for water. If it is a simple transfer application, then the most cost-effective material will be best.

However, if it involves abrasive solids or there is another variable to consider, then an alternative material may be a better selection. Some materials also are more flexible and ensure better performance when pumps prime which is another factor only known by us when specifying models.

Diaphragms, Balls and pump casings can be impregnated with carbon to ensure conductivity and prevent the buildup of static or sudden discharge causing ignition. Each pump is given an ATEX rating and can match the ATEX rating of the zone it is intended for.