Head vs Pressure

The discharge pressure of a pump is commonly referred to as head or pressure, but head and pressure are not the same across all liquids. It often causes confusion leading to a miscalculation of the correct pump specification to use.

What is head?

Head is the height of fluid typically expressed in (MLC) Metres of Liquid Column or represented with the unit M. This unit is independent of fluid type.

What is pressure?

Pressure is fluid dependent and relative to fluid density. A calculation of the pressure will change according to the fluid’s specific gravity.

Manometers on pumps indicate suction and delivery pressures, and the corresponding differential pressure, which does not take into account the specific gravity of the fluid being pumped meaning any readings provided need to be checked against the fluids specific gravity to calculate the differential pressure being produced.

Head to pressure conversion Formula

To convert Head in Metres to Pressure in Bar a formula is required.

Metres Head to Bar Formula

![]()

The formula is Pressure (P) x Head (M) x Specific Gravity (SG) Abbreviated to P x H x SG

Abbreviated to P x H x SG

Pressure = 0.0981 x M x SG

Example:

Water at 10M Head - Water has a specific gravity of 1, therefore 0.0981 x 10 x 1 = 0.981 Bar

Heavy Fuel Oil (HFO) at 10M Head – HFO has a specific gravity of 0.97, therefore 0.0981 x 10 x 0.97 = 0.952 bar

Meaning if a pressure of 0.952 bar is showing on a pressure gauge the head being produced for HFO is actually 10M

Feet to pressure in PSI Formula

![]()

The formula is Pressure in PSI (P) x Head (ft) x Specific Gravity (SG)

Abbreviated to P x Head(ft) x SG

Pressure = 0.434 x Ft (') x SG

Head in Bar to Pressure in M Formula

The formula for converting pressure in Bar to Head in M:

![]()

Head unit (H)= 10.197

Pressure (p)= bar SG = Specific Gravity

SG = Specific Gravity

Convert Pressure in PSI to Head in Feet Formula![]()

H = 2.31 * Pressure / SG

P= Pressure (PSI)

H = Head (ft)

SG = Specific Gravity

How to find power absorbed

What is absorbed power?

The absorbed power is the power consumed by the pump during operation at the required duty point. Although a pump may be fitted with a larger motor than is required for the duty, the power absorbed is usually indicated on the pump curve with an intersecting line of where the pump is expected to perform.

What is Specific Gravity (SG)?

Each liquid has a relative mass dependent on its volume. A figure (SG) is given to fluids to identify how dense the liquid is. Water has an SG of 1, with some oils having an SG around 0.83 meaning they are less dense than water. As they contain less relative mass (0.83 being < 1) they are lighter, which is why in the attached picture oil floats on top of the water.

Power Absorbed by Pump Calculation

The density and pressure directly affect the power absorbed by the motor during operation. The amount of power absorbed by a motor during operation is multiplied by the SG to calculate the power absorbed.

Absorbed power calculation

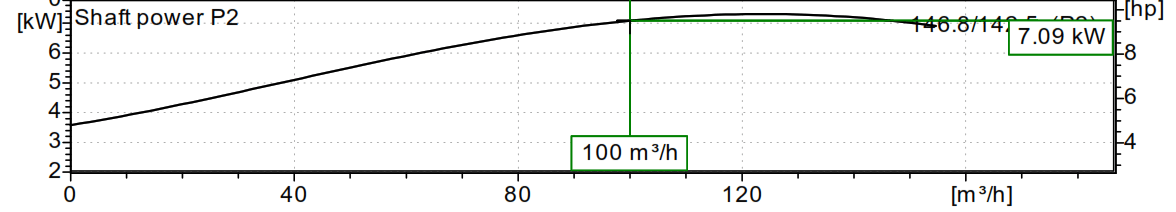

E.g.. If the absorbed power at the duty point is 7.09kw as in the above curve this is based on water.

If the density of a liquid is 1.3 then the power absorbed would be 7.09kw x 1.3 = 9.217Kw at duty, meaning the motor would need to be at least this size to not trip.

If the SG of a liquid is less than water for example and a light oil the SG would be 0.83 meaning the power absorbed would be 0.83 x 7.09kw = 5.88Kw meaning a smaller motor could be installed.

As a pump operates according to the system it is installed in, care will need to be taken to ensure the absorbed power at the highest point of the curve is larger than the density multiplied by the SG.

In the above example, the highest point is 7.5Kw so for water (7.5Kw x 1) max absorbed power will be 7.5Kw, and for a fluid, with a density of 1.3, the maximum absorbed power would be 7.5Kw x 1.3sg = 9.75Kw. A motor greater than 10Kw would be advisable. Read more about why a pump may be fitted with a larger motor.

Head loss vs pressure loss

Head loss refers to the pressure loss (friction) imparted on a fluid as it travels through components in a system. All parts from straight pieces of pipe, to bends, valves, heat exchangers and couplings create different levels of friction loss.

Different angled bends such as 45° bend compared to a 90° will create different levels of loss in a system. Each item has a pressure loss value known as a K factor detailing the losses caused by each part.

Geodetic Head

This is the physical difference in height between the liquid level and the highest discharge point. This figure can often change when pumping from tanks or pits where the level can fluctuate. There is often a misconception that the Geodetic head is measured from the depth of the suction pipe, but this is not something considered when calculating this but is instead the difference in fluid levels.

Pump Derating

As pump curves are based on water, a correction factor must be applied to a curve to correct it against the liquid being pumped. This is applied when a fluid is more viscous than water, viscosity fluctuates with temperature or if solids are present.

There are several factors which must be considered when correcting pump curves from particle size, temperature, to the properties of a liquid, so it is always better to discuss curve correction with one of our engineers.

If you have an application you would like to discuss with one of our Technical Sales Engineers, contact us.