Rotary Vane Pump for Marine Engine Lubrication

Urgent Requirement for an Engine Oil Lubricating System on a Marine Vessel

Urgent Requirement for an Engine Oil Lubricating System on a Marine Vessel

A marine vessel was in urgent need of a reliable solution for their engine oil lubricating system. The pump was required to transfer lube oil through a filtration system before entering the main engine. The oil has a viscosity of 40cSt, a density of 850kg/m³ and needed to be transferred at a flow rate of 6m³/hr at 2.5 bar.

The lube oil pump is fed via a large holding tank with a level switch to shut the pump off for protection in the event the tank empties. It was important to the engineer that the unit can maintain the necessary flow rate regardless of fluctuations in pressure. This was because quite often the duplex filter can become partially clogged and this can increase the pressure in the pipeline up to 5 bar.

Selecting our NRBAR-1.5 Rotary Vane Pump with Built in Pressure Relief Valve as a Solution

Selecting our NRBAR-1.5 Rotary Vane Pump with Built in Pressure Relief Valve as a Solution

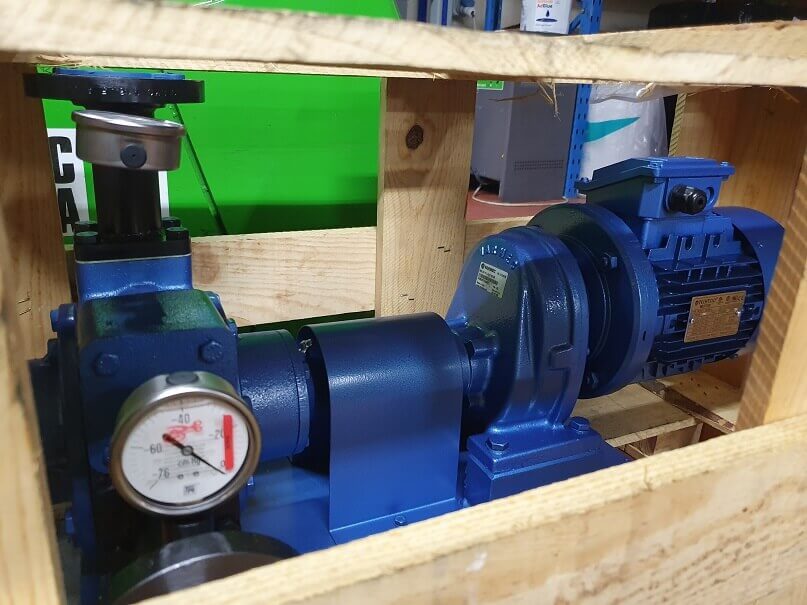

We specified our NRBAR-1.5 model of rotary vane pump design fitted with a 1.1Kw motor and gearbox to reduce the operating speed to 400RPM. This is a positive displacement pump and can therefore sustain the specified flow rate even if pressure fluctuates. This design is fitted with a built-in pressure relief valve that opens when back pressure reaches a certain level, this recirculates the fluid within the head protecting the unit and system. The relief valve was a very useful feature for the engineer as it was made clear that the filtration system was prone to clogging.

The NRBAL series is typically directly coupled to a motor when transferring low viscosity liquids such as diesel fuel or solvents. We couple units with a gear box when handling higher viscosity fluids such as lube oil or crude oil. The lower RPM produces a much gentler pumping action and enables it to transfer thicker fluids with ease. When fitted with a gearbox, they are excellent at handling any similar applications, which include lube oil bunkering, blending and cooling.

Additional Benefits of Using A Rotary Vane Pump

Other benefits of our rotary vane pumps are; the ability to self-prime from dry, they are quiet running and produce minimal vibrations, they are also simple to maintain and can handle small quantities of vapour.

As the customer stated the pressure can fluctuate within the system, we installed suction and discharge pressure gauges to provide the engineer with a clear view of what is happening within the system.

Below is the specification of the equipment that was installed:

Model: | NRBAL-1.5/1500-1.1kW, with built-in Bypass/Safety Valve and Pressure Gauges on Suction and Discharge |

Fluid: | Lube oil with a viscosity of 40 cSt |

Materials: | Cast Iron casing and Viton mechanical seal |

Flow rate: | 6 m³/hr |

Pressure: | 2.5 Bar |

Motor and Gearbox: | 1.1Kw, 400RPM |

Interested to learn more about Vane Pumps? Read more