Peristaltic Pump for Flocculant Transfer at Mineral Processing Facility

Enquiry from an Engineer at a Mineral Processing Facility

Enquiry from an Engineer at a Mineral Processing Facility

We received a phone call from an engineer at a mineral processing facility that watched our case study video of a peristaltic pump we supplied to a papermill for water based ink transfer, needless to say he was extremely impressed and could see how our AMP range can help with their existing process.

They were currently using a progressive cavity pump to transfer flocculant to a belt press and thickener for a separate process. The progressive cavity pump was failing frequently and required constant maintenance and repair, this was a costly and lengthy process leading to considerable downtime. Progressive cavity pumps can be difficult to repair and often need to be sent to a specialist company for repairs to be undertaken.

Our case study video demonstrated to him how simple and quick peristaltic pump maintenance is. With the only wearing part being the hose, stocking parts is easy and cost effective, maintenance can also be performed by low skilled labour at their facility.

After looking at the specification of the existing pump and discussing the process, it was ascertained that a flow rate of around 900L/hr and a pressure of around 1.5 bar was required at peak operation. The current pump was being controlled via a variable speed drive to alter the motor speed and pump output, also the pump was often left unattended for long periods of time.

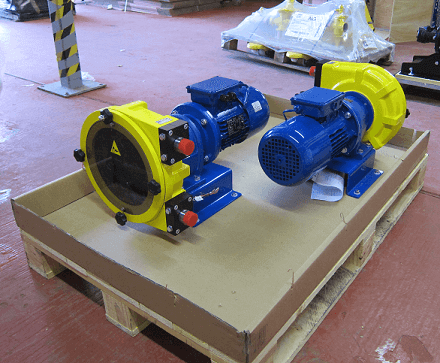

Our AMP 22 Peristaltic Pump with Variable Speed Drive and Forced Air Cooling System

Based on the information provided, we selected our AMP 22 model peristaltic pump fitted with a motor suitable for operation via a variable speed drive. We suggested that the motor be fitted with a forced air-cooling system to allow the operator to run the motor at very low speeds without fear of overheating. As the flocculant and thickener are neutral, a natural rubber (NR) hose was selected and we recommended that a spare hose and silicone grease was ordered to avoid any possible downtime. Due to the existing pump being left unmanned, we selected a hose leakage system for the hose pump to warn the operator if the hose bursts so that repairs can be performed quickly with no loss of downtime.

After reviewing our specification and suggestions, and considering the obvious benefits of easy maintenance, easy stocking of parts and dry running, the customer quickly ordered 2 pumps for their processes.

Below is the specification of the peristaltic pump that was installed:

Model: | AMP 22 Peristaltic Pump with Gearbox, VFD rated Motor, Forced Cooling and Hose Leakage Sensor |

Fluid: | Flocculant and thickener at 350 cSt |

Materials: | NR (Natural Rubber) hose |

Flow rate: | 44 – 1196 L/hr |

Pressure: | 0.9 – 1.73 Bar |

Motor: | 1.1Kw, 3 - 81RPM, 3 – 75Hz, VFD Rated Motor, with PTC Sensors and Forced Air Cooling |