Peristaltic Pump for the Transfer of Mine Tailings Slurry

Coal Mine Enquiry

Coal Mine Enquiry

Quite often we are contacted by engineers that are experiencing problems with their current pump installations. This was the case with a coal mine in South Africa, the pumps for their tailing’s slurry process were failing rapidly and regularly, causing leaks and leading to considerable costs and downtime. This was mainly due to the large quantities of abrasive particles in the sludge wearing the key components in their centrifugal pump, such as the mechanical seal, impeller and casing.

Maintenance was also an expensive, long and complicated process that was adding to their frustration. Various spare part components in large quantities were required to be stocked at their facility to ensure production was not interrupted. Due to the complicated process of repairing their existing pumps, the equipment had to be sent offsite to a specialist engineering company every time repairs were undertaken.

Tailings is a by-product sludge that is created from the mining process, is it a waste mixture of ores and water, commonly created from coal or iron. The waste slurry needs to be disposed of in a safe and efficient manner, so that the water can be separated, therefore it is important that a reliable and simple to maintain pump is installed.

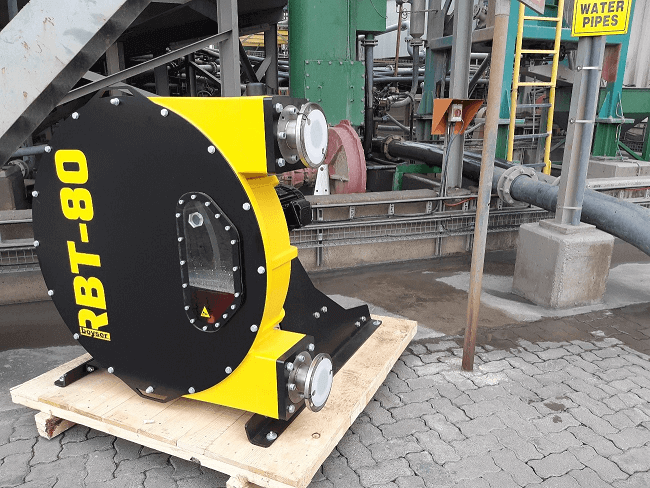

Our Cost Effective, Easy to Maintain RBT-80 Peristaltic Pump Solution

Due to our experience with applications such as this, we knew the ideal solution was our RBT-80 peristaltic pump. Often referred to as a hose pump or squeeze pump, they are the easiest to maintain of any pump type available. There is only one component within the casing that encounters the fluid being pumped, this is a rubber hose that can be manufactured in various materials to guarantee chemical compatibility. As this is also the only wearing part, keeping spare parts is a simple and low-cost process, maintenance can also be performed by low skilled personnel on site in very little time.

Peristaltic pumps are run at very low speeds via a gearbox to create a gentle pumping action, this ensures abrasion is reduced to a minimum. Thanks to their unique design, they can handle high viscosity and solids laden fluids without risk of clogging. They can be run in reverse if required in the event the pipework is clogged, this is an excellent failsafe for applications such as this.

Hose pumps are self-priming by nature and can perform suction lifts up to 9 metres depending on the nature of the fluid, they can also run dry indefinitely without risk of damage. We fitted the RBT-80 pump with a leakage sensor for this customer as they often leave the equipment unmanned. This device signals the engineers via a control panel in the event the hose bursts/leaks, it is an early indicator of any problems and reduces downtime significantly.

This mine now has a reliable and effective pump installed for their slurry process. Downtime and maintenance have been reduced significantly, consequently they are saving thousands of pounds in maintenance costs. Only a spare hose and lubricant need to be stocked, and with minimal training, their onsite engineers can perform repairs the same day.

Below is the specification of the peristaltic pump that was supplied:

Model: | |

Fluid: | Mine Tailings Sludge |

Materials: | NR (Natural Rubber) hose |

Flow rate: | 16,000 L/hr |

Pressure: | 2 Bar |

Motor: | 7.5Kw, 23RPM |

Learn more about our peristaltic pump range here