Hygienic Flexible Impeller Pump for Syrup Transfer at Bakery

Hygienic Transfer Pump Enquiry for Transferring Syrup

Hygienic Transfer Pump Enquiry for Transferring Syrup

A bakery specialising in cakes, flapjacks and muffins required a hygienic pump for transferring syrup from a large holding tank to several smaller tanks for later adding to their cooking processes. It was vital that the pump be easy to clean both inside and out, all other equipment on site is frequently sprayed and washed with high temperature water. Also, due to the limited space available at the installation, the inlet and outlet pipework is at 90°, meaning the pump connections must be in line with this.

North Ridge's FDA Approved Flexible Impeller Pumps

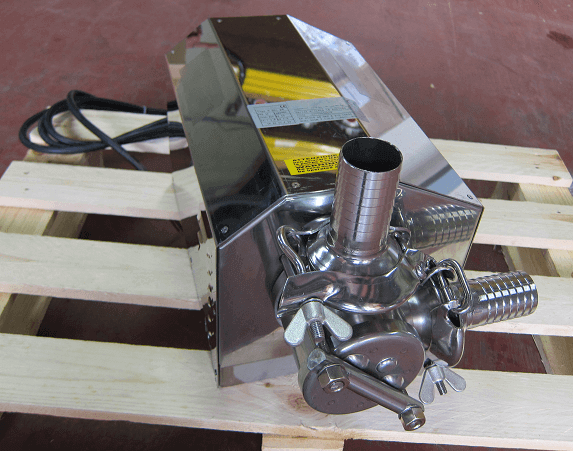

Syrup is viscous and requires careful consideration when the pump selection is made, it is critical the pump speed is low enough to produce a gentle pumping action that will correctly draw the syrup without just drawing air. Our flexible Impeller pumps are perfect for this application as they produce a gentle pumping action, they are FDA approved with a stainless steel 316 casing and rubber impeller, they can also be cleaned in place by simply flushing the pump with hot water and a cleaning solution. Additionally, we supplied the pump with Garolla food grade connections and a stainless-steel shroud to protect the motor so that it can be sprayed for cleaning to maintain hygiene standards.

90° Inlet and Outlet Connections In line with the Existing Pipework

Further to the above bespoke requests, we manufactured the pump with inlet and outlet connections at 90° to ensure a simple installation with the limited space available on site. Our flexible impeller pump range is configurable to meet a wide range of needs and applications, these include connection options of tri-clamp, RJT, BSP and SMS, the option of built in variable frequency drive for controlling the flow rate, dry run protection, as well as a mobile trolley for easily moving the pump around site.

We recommend this pump range for various food and hygienic fluids such as milk, yoghurt, honey and even toothpaste. With the further flexibility of being self-priming and the ability to supply the impeller material in EPDM, NBR, EPDM, silicon and natural rubber, these pumps can handle most thin and viscous food products with ease.

Below is the specification of the supplied pump:

Model: | FIPMinor40 Flexible Impeller Pump, with Hygienic Stainless-Steel Shroud/Enclosure |

Materials: | Stainless steel 316 casing, EPDM mechanical seal and EPDM impeller |

Flow rate: | 103 L/min maximum |

Head: | 24m maximum |

Inlet/Outlet: | 1 ½” Garolla stainless steel connections |

Motor: | 1.5Kw, 900RPM, 400V/3Ph/50Hz |