Air Operated Diaphragm Pump Kit for Bilge Water

Assisting our Customer in switching to an Air Powered Bilge Pump

We help customers as much as possible to solve any issues they are experiencing, quite often this involves supplying additional components rather than just the pump. Understanding the installation and the ultimate goal of the project allows us to paint a complete picture and specify ancillary items that will make the operation as simple and painless as possible for the customer.

A regular customer of ours that operates a wide range of marine vessels planned to switch from an electrically powered to an air powered bilge pump, although needed guidance on all the components required to complete this process. Their existing bilge transfer was undertaken by a progressive cavity pump, a perfectly suitable unit for this process, however this particular client wanted to save on the cost of spare parts.

North Ridge's Selection of our Simple, Low Cost, Versatile Boxer 50 Air operated Double Diaphragm Pump

After discussions to understand all the requirements, we identified the flow rate required and selected our Boxer 50 Air Operated Double Diaphragm Pump with aluminium casing and NBR internals. This type of pump is one we recommend to a lot of marine engineers as it is extremely versatile and simple and low cost to maintain. As bilge tends to contain sea water, lube oil and diesel, aluminium and NBR are ideal materials to resist corrosion and extend the life of the pump.

Diaphragm pumps, often referred to as AOD pumps, are reliable and flexible due to their ability to self-prime, run dry indefinitely, produce pressures up to 8 bar, handle viscous fluids and solids. They are from the positive displacement family and therefore the flow rate is directly proportional to the air pressure entering the motor, this allows for the flow rate to be adjusted simply by controlling the air pressure via a valve on the motor or airline. This simple yet useful feature permits the pump to be used for various applications in other locations on the ship that may require higher or lower flow rates, such as effluent or slop transfer.

Supply of a Complete Plug and Play Kit to Assist with the Transition

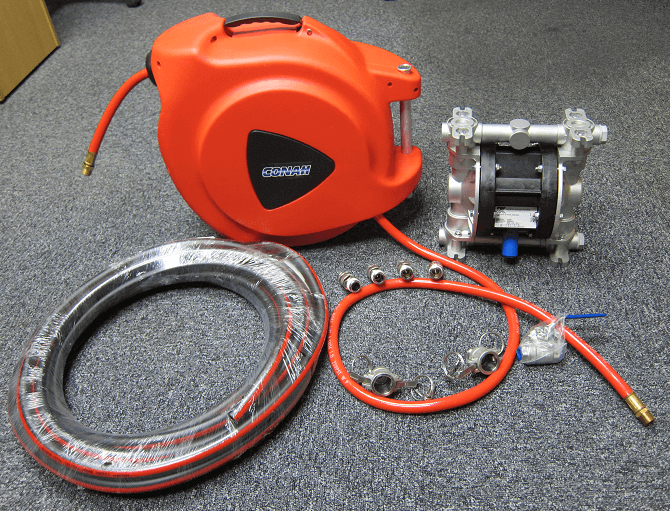

To assist the engineer with the transition from an electric powered to an air powered pump, we supplied various additional items to effectively make a plug and play solution. Along with the pump, we delivered a complete kit including reinforced suction hose, a retractable air hose reel with hose, quick release cam coupling, hose tail, ball valves and quick release air connectors. This was an excellent project to be involved with and the customer is exceptionally happy with the long-term cost savings and the ease of the changeover.

Below is the specification of the bilge water AOD pump that were supplied:

Model: | |

Fluid: | Bilge water containing sea water, lube oil and diesel |

Materials: | Aluminium Casing, NBR Diaphragms, NBR Balls, Aluminium Ball seats and NBR O-Rings |

Flow rate: | Up to 60 L/min |

Pressure: | Up to 8 Bar |

Inlet/Outlet | Fluid connections ½” (DN15), Air connection 3/8” F |

Motor: | Air |