Hygienic Peristaltic Pump for Luxury Cosmetic Manufacturer

Luxury Cosmetic Manufacturer's Enquiry

Luxury Cosmetic Manufacturer's Enquiry

The cosmetic industry has been one of the fastest growing industries in the world in the past few years, with a current global market value of more than 300 billion GBP and expected to reach £500 billion by 2025. Skin and hair care products are among some of the most bought products in this industry.

We received an enquiry from a luxury shampoo and skincare manufacturer in the UK, they needed to increase and at the same time improve their current process as they were not happy with the equipment they were using to transfer some of their signature products. After discussing their process in detail, we identified several ways where we could indeed improve this, potentially saving them time and money. Accelerated pump wear was one of the problems they were having, but the most concerning issue was product agitation, the old pump was not originally specified for handling the new product, a honey-like viscosity luxury shampoo.

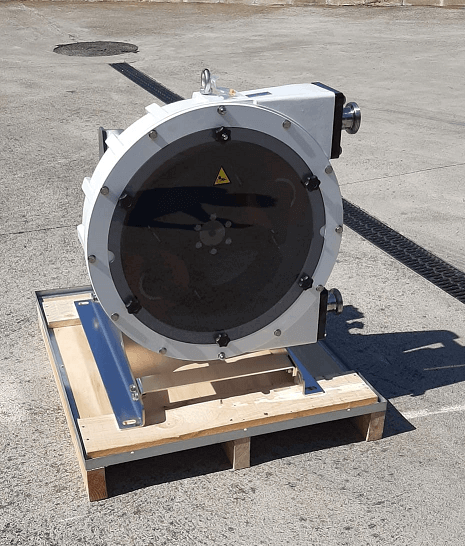

Our Shear Sensitive FMP60 Peristaltic Pump

The solution was simple, our customer required a shear sensitive pump, capable of handling the product without causing agitation or froth, they also required the pump to handle a luxury face cream which was a much more viscous fluid. We supplied the customer one of our FMP60 peristaltic pumps, with DIN 11851 stainless steel sanitary connections, food-grade hose, complete with a 3Kw motor.

When handling shear sensitive fluids, our FMP peristaltic pumps are almost always the best solution, no other technology has a more gentle pumping action than these type of pumps, furthermore they can handle viscosities up to 30,000 cSt as well as being incredibly easy to maintain as the only wearing component is the internal hose. This made things a lot easier for our customer, not only because of how simple it would be to service a pump which only has one wearing part but also because the hose was the only component in contact with the fluid, making the CIP cleaning process much more straightforward than before. Our customer used an ozone & water mixture to clean the pump, we selected food-grade Norprene® as the hose material, which besides being compatible with the cleaning liquid is also an excellent hygienic material.

When selecting a peristaltic pump for any application, it is important to pay special attention to the material compatibility of the hose as not choosing this correctly could cause immediate leakage by hose failure.

Some of the reasons why our FMP peristaltic pump range is ideal for this application:

• Seal-less – Minimising the risk of leaking.

• Shear sensitive – Very gentle on the product being pumped.

• Capable of running dry indefinitely – Without the need to install any other device.

• High dispensing accuracy – Excellent for dosing applications.

• Easy to clean as the inner hose is the only part in contact with the product.

• Suitable for food-grade applications – FDA approved.

• Requires low maintenance – Economical to run.

Specific details of the pump supplied to our customer are as follows:

Model: | |

Materials: | Norprene hose and stainless steel connections |

Capacity: | 5.3 m³/hr |

Max. Head: | 80 m |

Inlet/Outlet: | NW 50 DIN 11851 – Stainless Steel |