Shear Sensitive Fruit Transfer Pump

Customer's Process for Transferring Apple Pieces

A Fruit processor was having issues with their Apple piece Transfer Pump. The unit had been in use for 20 years, and was coming towards the end of its useful life.

The customer was not happy with their current supplier, struggling with lax service, expensive spares and support troubleshooting ongoing problems. They wanted to upgrade their existing unit as well as overhaul their control panel to increase output to around 1200L/hour.

The mixture consisted of fruit pieces which were between 2.5-3” long, comprising of concentrated apple chunks, water, sugar, and starch for apple pie filling. The pieces had been cooked, were very soft and could not be damaged. The fluid had a very high concentration of solids, and the pump needed to produce up to 1200L/hour to fill pies at the required rate, but also have the ability to lower output without loss of pressure.

Various low shear pump technologies were explored such as flexible impeller, lobe, progressing cavity, gear and peristaltic however none were able to convey the pieces without damage which was a requirement for this process.

Our Unique Very Low Shear Sinusoidal Design Solution

North Ridge selected a unique very low shear sinusoidal design of pump. Named after a sound wave of smooth repetitive oscillation, in this design of pump an S shaped impeller gently rotates within the pump head, lightly conveying solids, intact without risk of damage or breakage from the inlet to the outlet.

The pump head is partitioned into 4 chambers via the impeller, which can rotate at any speed up to full motor speed. The motion ensures very low pulsations, high suction capabilities and provides a constant pressure regardless of flow rate (positive displacement).

The impeller is shaped in such a way that pieces are scooped and transferred towards the outlet. The impeller does not have a tip unlike other low shear designs of pumps or have to pass through it which can cause pieces to be broken, or damaged.

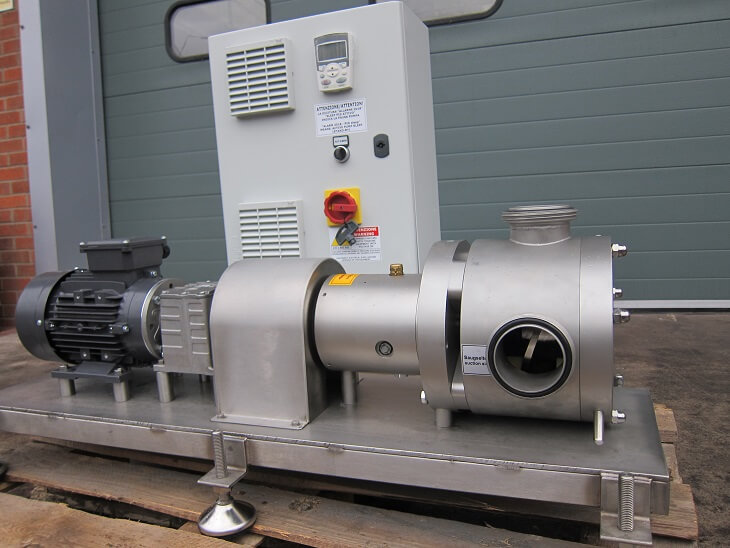

We supplied the pump complete with variable speed panel to enable easy flow control in production. The unit was mounted on a hygienic stainless steel baseplate with adjustable feet for easy levelling and connection to their pipework. The mechanical seal was oil (hygienic) lubricated.

Our solution ensured product consistency from manufacture to final output enabling consumers of the apple pie to experience fruit chunks in their fullness.