Air Operated Diaphragm Pump for Glue Recirculation

Customer's Requirement For Recirculating Water-Based Glue

Customer's Requirement For Recirculating Water-Based Glue

A UK based market leading manufacturer of carrier bags contacted us requiring a replacement pump for recirculating water-based glue in one of their machines. They specialise in making printed carrier bags, printed paper bags, bags for life, printed mailing bags and eco-friendly carrier bags. In addition to these products, they also produce a range of retail packaging across a wide array of sectors.

They have many processes in their factory as they handle the entire manufacturing cycle from start to finish, mainly involving glues and inks in addition to various chemicals. On this occasion one of their glue machines had failed, the existing pump was old and all markings in relation to brand, materials and performance had worn away over time.

This machine is crucial to their manufacturing process and is used for all their product ranges, they were very keen to get a replacement pump that would match their existing unit in performance but also be extremely reliable. After discussions with their engineering manager, it was ascertained that they were not content with the existing pump and hoped to get a new unit that would perform a higher flow rate as on certain occasions this is required, they wanted the flexibility to use this on demand.

Factors to Consider when selecting the Pump

After receiving photos and dimensions, we determined it was an air operated diaphragm pump, the casing must be polypropylene, the diaphragms PTFE and the connections were 3/8” and the flow rate currently being produced was around 20L/min. The installed pipework is ½” so they have the facility to accept a larger pump and therefore a higher flow rate.

The customer was unable to provide viscosity figures for the glue, this is crucial information that determines the material required for the balls and balls seats inside the pump. We therefore went for the safest option and selected stainless steel 316 balls and ball seats as these are better with higher viscosity fluids. Due to the machining process, they grant a better seal, and the weight of the balls allows them to fall easily through thicker liquids to from the seal, this also assists with self-priming when the pump is situated above the fluid level.

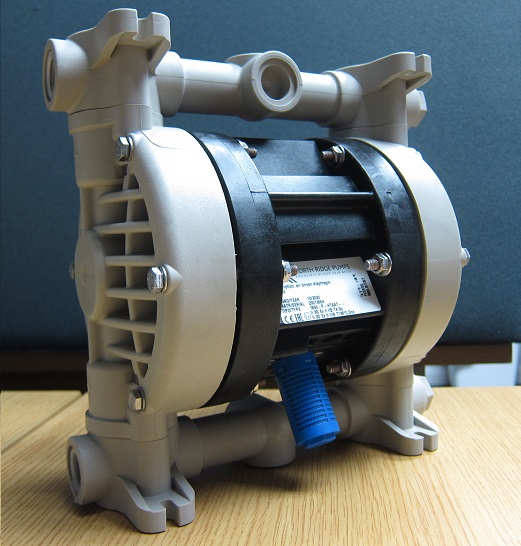

Our Boxer 50 AODD Polypropylene Pump For High Viscosity Fluids

We supplied our Boxer 50 air operated diaphragm pump, this has ½” connections and produces a flow rate of 60L/min at maximum air pressure. Often referred to as AOD pumps, these units are exceptional at handling liquids such as glues, inks, or other high viscosity fluids. They are flexible for a wide range of installations as they are positive displacement by nature, they can self-prime, produce pressures up to 8 bar, run dry as well as handle high viscosity fluids and solid particles. The flow rate output is easily controlled by the operator, this can be increased and decreased by simply controlling the air pressure into the motor via a valve.

To further add to the reliability and flexibility, this range can be manufactured in other materials such as AISI-316 stainless steel, Aluminium, and PVDF alongside other diaphragm materials including EPDM and NBR. Our diaphragm pumps are Atex Zone 2 compliant as standard for installation in non-safe areas, we can also produce them to Atex Zone 1 standards for pumping flammable fluids.

This customer now has a new reliable pump for their glue process and the flexibility to increase demand if required, the patented anti-stall motor design also means the air pressure can be lowered significantly to produce extremely low flow rates for dosing without stalling and stopping production. It can also run on non-lubricated air, a unique element not typically available in other designs on the market.

Below is the specification of the AOD pump that was supplied:

Model: | Boxer 50 Polypropylene Air Operated Double Diaphragm Pump |

Fluid: | Water based glue |

Materials: | Polypropylene Casing, PTFE Diaphragms, Stainless Steel Balls and Ball seats. |

Flow rate: | Up to 60 L/min |

Pressure: | Up to 8 Bar |

Inlet/Outlet: | Fluid connections ½” (DN15), Air connection 3/8” F |

Motor: | Air |