Flexible Impeller Pumps for Detergent Transfer

Process Overview

Process Overview

A UK producer of laundry products, specialising in detergents and fabric softeners required 4 versatile pumps for use in their manufacturing processes. With a wide range of chemicals of various compositions and viscosities, it was essential that the pumps be capable of handling different liquid types without losing performance or succumbing to corrosion.

In addition to the varying viscosities, it was important to be aware of the shear sensitivity of the fluids, the wrong pump technology could be too rough on the detergents and cause damage, ultimately leading to waste and lost revenue. Due to the layout of the facility, it was not possible to gravity feed the inlet of the pumps, the units needed to be self-priming and capable of performing a suction lift from dry.

Our Low Maintenance, Low Shear Solution

After acquiring specific information on viscosity figures and chemical compatibility, we found the ideal solution with our flexible impeller pumps. These are extremely versatile with their ability to self-prime from dry, handle high and low viscosity products while also being available in a wide range of materials. In addition to these benefits, due to their positive displacement pump design they produce a gentle pumping action that makes them excellent when transferring shear sensitive products.

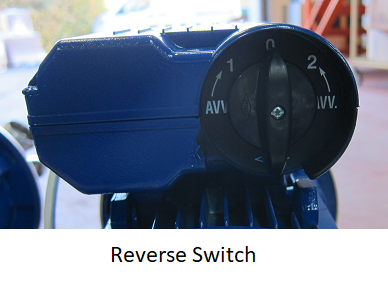

The engineer requested 2 sizes of pumps for different processes, 2 units for moving 130L/min and the others for 250L/min. The supplied pumps were installed with stainless steel casings, EPDM impellers and EPDM mechanical seals for chemical resistance. To assist the operator on site, we fitted reverse switches to the motors, this enables to pumps to be ran in reverse by a simple flick of a switch, this is ideal in case a container is overfilled or there is a blockage in the pipework that needs removing. As these are units are crucial to their operation, we supplied spare impellers, O-rings and mechanical seals to ensure there was minimal loss of production when maintenance is required.

Other Uses

Due to their flexibility, flexible vane pumps are used in applications such as this in factories and manufacturing plants worldwide. Fluids that often pose a challenge for other pump technologies are easily handled by this range, common tricky fluids include milk, cream, toothpaste, honey, vegetable glycerine, water-based glues, and paints. With the ability to fit these units with other impeller materials, such as NBR, Silicon and Natural Rubber, the list of compatible liquids is vast.

Key Benefits

• Self priming up to 6m without the requirement of a non-return valve

• Excellent for handling shear sensitive fluids due to the smooth non-pulsating flow

• Viscosity capability of 50,000cp for the largest model

• Up to 25mm solids handling capability depending on pump size.

• Reversible via switch on the motor

• Various impeller materials, including NBR, Neoprene, EPDM, Silicon and Natural rubber

• Various connection types, including DIN, BSP Male and Female, Triclover, SMS, RJT, Friederich, Garolla and Macron.

• Certain models are available with 2 speed motor

• Various pump head orientations depending on application requirements

• Integrated manual or spring-loaded bypass available for certain models

• Motor options include 12V DC, 24V DC, 230V Single phase and 400V Three phase

• Wide range of accessories available including mobile trolley, control panel, bypass, barrel filling kit, carry handle, flow meter, dry run protection, pressure switch, level sensors, remote control, and motor shroud.