7 Steps to Reduce Pump Maintenance

7 Steps you can take to reduce Pump Maintenance

Has your maintenance budget shrunk for this year? Are you frequently having to replace the same spare parts consistently?

If you are frequently having to maintain your pump leading to process stoppages and downtime it could be a sign of another problem. Here are 7 steps you can take to reduce the time spent on pump maintenance and improve plant efficiencies and process uptime:

Have a Lubrication & Inspection Schedule

Insufficient lubrication & too much lubrication is often a cause of bearing failure.

If a seal leak remains undetected, fluid will leak from the pump casing into bearings which if left unresolved, can lead to catastrophic pump failure.

If a seal leak remains undetected, fluid will leak from the pump casing into bearings which if left unresolved, can lead to catastrophic pump failure.

Our maintenance schedule provides indicative time frames for scheduling maintenance.

Check Actual Pump Duty vs Design Duty

Over time a pump's performance may deteriorate or the conditions it faces change. A pump's performance should always be checked to ensure it is not cavitating. A doubling in wear ring clearances can mean NPSH increases by 50%. This pump suffered catastrophic failure after cavitating resulting in a cracked impeller.

Drop In Replacements

Pump Inserts or bareshaft pumps ensure replacement pumps can be placed into the process with minimal disruption or downtime ensuring process uptime. Having Pumps mounted on plinths ensures liquids which spill during maintenance can be hosed or jetted away easily and also ensure that maintenance is performed at an easy working height without engineers having to adopt uncomfortable or awkward working positions.

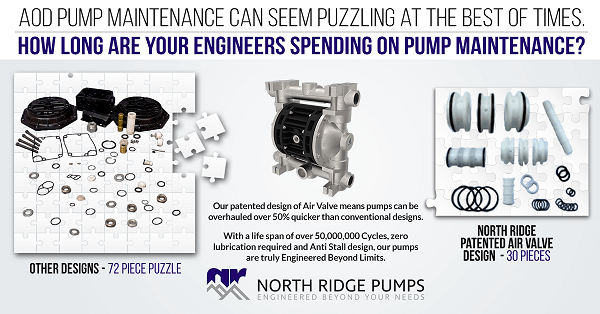

Change Pump Design

Some designs of pump, like in the below comparison have far more spare parts than other models. Maintenance can become puzzling trying to refit all parts, along with time pressure constraints meaning mistakes are likely.

Maintenance can often take longer than is required on inferior designs which is not always apparent at the time of purchase of a pump. The time is taken to service some pumps can be reduced by up 50% when specified correctly.

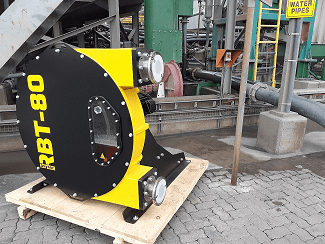

Change Pump Type

Not all pumps are created equally. Some designs are better suited for abrasive slurries, can accommodate dry running and better suited for 24/7 operation. Changes in pump types can mean energy savings of between 20-30% with an equivalent reduction in spares costs.

By re-evaluating your current application against the pump type in use, could mean another solution is better suited as in this case study

Increase Pump Size

Quite often a pump is installed in an application based on cost rather than factoring in full application details. Units may be operating too fast meaning spares are being replaced frequently. Increasing the pump size and running it slower is often a way of ensuring longevity by reducing wear.

Pump Monitoring

Remotely monitoring your pump can mean early detection of a reduction in flow or pressure, vibration, excess temperature or increase in power consumption.

This enables condition-based maintenance to be undertaken before failure and requirements become urgent.

It also means pumps are dismantled when required rather than unnecessarily.

If you are interested in reducing labour costs further, our article provides 17 ways in which a pump can be automated.