Twin 8” Duplex Strainers for Water Glycol Mix

Application Overview

Plastic bottles are extensively used throughout industry. They are a convenient, safe and essential way of distributing decanted Water, Oils, Lotions, Gels and Creams to consumers across the globe. Within the UK over 7.7 Billion plastic water bottles alone are used per year. (Water UK) <https://www.water.org.uk/news-item/national-refill-day/>

A plastic bottle manufacturer of HDPE bottles producing over 140 Million bottles per year operating 24 hours a day, 7 days a week contacted us requiring a strainer for removing fine particles from a Water / Glycol mix cooling recirculation line. The coolant was being used for the cooling of dies, with the strainers being required for equipment and pump protection. It was a solution requiring a large strainer due to 600M³H passing throughout the plant at up to 6 Bar. Plastic bottles can be made in two ways – by plastic injection, or extrusion blow moulding.

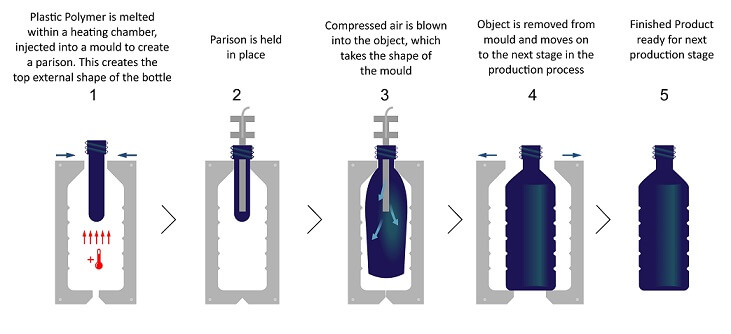

Injection Blow Moulding

In this process plastic polymer is melted within a heating chamber and injected via nozzles into a mould. This provides the top external shape of the bottle and is known as a parison.

The parison is removed from the mould and placed into another mould where the parison is clamped, and compressed air blown to form the shape of the mould which is in the shape of a bottle.

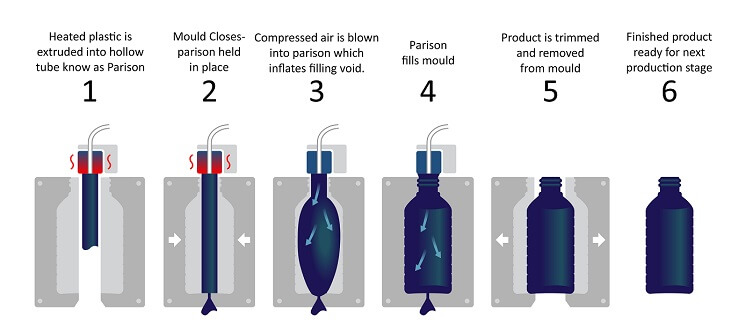

Extrusion Moulding

This is a similar process to injection moulding in that heated plastic is pressed through a die to produce a particular shape such as a hollow tube called a parison. The parison is held in place, with compressed air blown into it, with the parison forming the same shape as the mould.

The bottle is trimmed and removed and ready for next stage which may involve heat treatment, and further customization including branding.

The dies and injection equipment used in the manufacture of such goods requires constant cooling, and our customer required a 12” duplex Strainer urgently to handle the 600M³H flow.

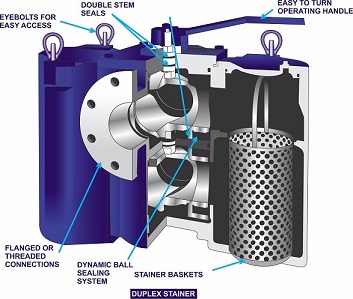

Duplex Strainer Working Principle

A duplex strainer is perfect for any operation where production operates 24/7. A duplex strainer consists of two large strainers connected via a central manifold. During normal operation fluid flows through both sides of the strainer, however should one side become clogged, flow can be diverted to one strainer whilst the other is cleaned without process stoppage.

A set of differential pressure switches enables operators to easily see when a filter is becoming clogged. They sense the pressure between the incoming and outgoing flow of the strainer, and as backpressure increases – meaning a blockage is present, an indicator shows the level of blockage from green indicating normal operation, yellow meaning the basket should be scheduled for clean, and red meaning that a service is due as soon as possible.

Differential pressure switches are available as unpowered versions enabling easy inspection in manned areas, or with a wired DIN plug to connect to an alarm and control panel if the installation is remote or equipment is not frequently inspected.

Typical applications for such units include fuel oil filtration, raw water solid removal, food filtration, filtering of adhesives and seawater.

Due to time constraints we explained a 12” Duplex strainer was not possible within the short lead time required, but we were able to offer two 8” Duplex Strainers in Cast Iron with customized baskets in under 3 weeks.

Having two 8” Duplex Strainers would ensure that the pressure drop was not excessive and that the high flow could be accommodated within the project deadline. The units were fitted with customized baskets providing the level of filtration the customer required, with 4 differential pressure switches enabling nearby personnel to easily observe when maintenance was required. All delivered in under three weeks.