External Gear Pumps for Constant Flow of Fish & Soy Oil for Animal Feed

They were looking for 4 hygienic pumps to transfer edible Fish and Soy Oil into a mixer for the manufacture of Animal Food. Soy and Fish Oil are a great source of Vitamins, Fat and Amino acids with its consumption helping to increase both livestock growth and yield.

Process Set Up

The pumps were being used on 2 separate duty/standby lines transferring the oil from separate IBCS into mixers via 1” lines. The containers were located in a low-risk area of the plant, to avoid the risk of feed contamination via pallet truck movements, and as such were over 40M away from the process, with spray nozzles fitted at the end of the line to ensure an even coating of oil within the mixers in the shortest possible time.

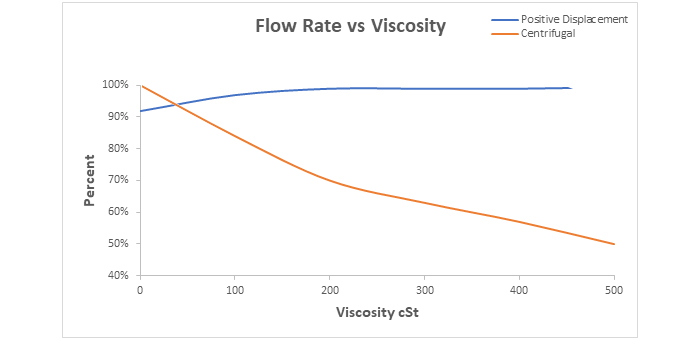

When handling oils, it is important to note that as viscosity can fluctuate with temperature, using a positive displacement pump ensures that a process will always receive the same flow rate which for this application was 2M³H at a pressure of 6 bar.

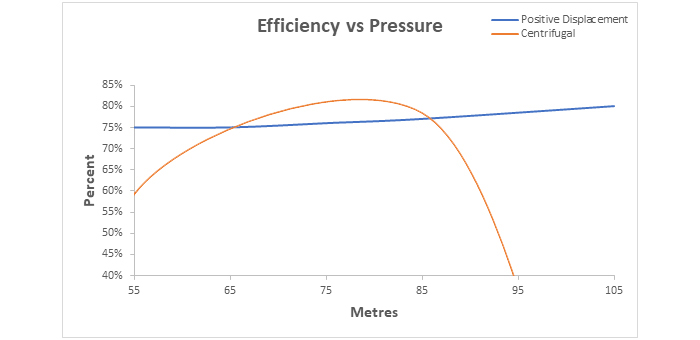

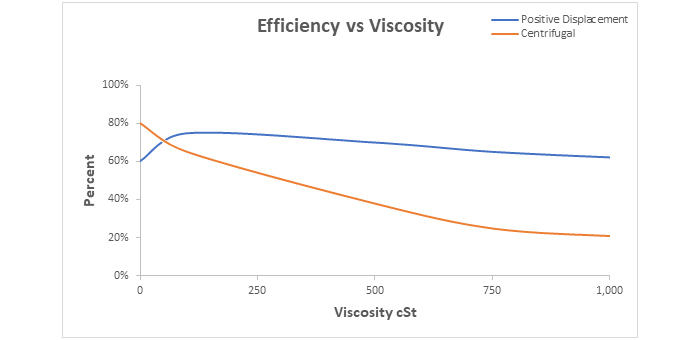

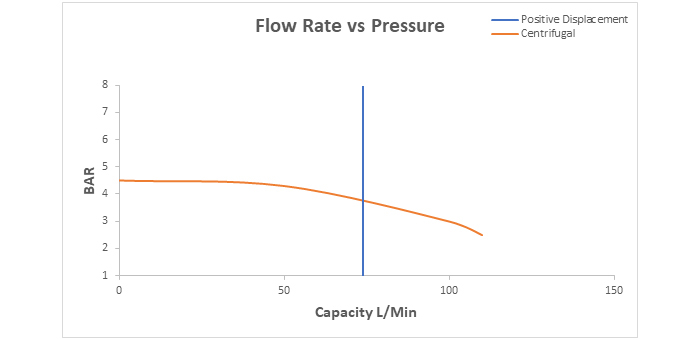

Positive Displacement Vs Centrifugal Flow, Viscosity & Efficiency

As you can see in the graphs above a positive displacement pumps flow and efficiency will remain almost constant against differing pressures, and viscosity.

This is due to the nature of its design and working principle meaning that during operation liquid is unable to recirculate back towards the inlet.

A centrifugal pumps efficiency will quickly drop as viscosity increases. This is because as the fluid becomes more viscous, the internal working design of a centrifugal pump allows fluid to recirculate back to the inlet, known as pump slip. Positive displacement pumps not only ensure that volumetric flow rate is consistent against a range of pressures, but in fact prefer viscous fluids with flow and pressure ranges increasing with viscosity.

Our Constant Flow Solution

We manufactured and supplied 4 off 1” MGHP External Gear Pumps manufactured with the Casing, Gears and Shaft in AISI 316 Stainless Steel, ensuring the pumps transferred the oil cleanly and without the introduction of contaminants.

The units were directly coupled to a 1.5Kw ABB motor running at 1450rpm, suitable for operation via a variable frequency drive without a gearbox, meaning the units remain compact, and ensuring that pump speed can be altered to control the amount of oil being dispensed.

If you have a project where you are looking to transfer Food, Oils or Chemicals and are unsure of the best solution, speak to us to see how we can help.