Mining Industry

Mining is a crucial industry used for the extraction of precious metals, stones, minerals and fuels. The mining industry incorporates a variety of mechanical processes ensuring maximum efficiency and safety.

North Ridge Pumps work with you to ensure your mine operates continuously without downtime in all processes covering all pump types from multistage pumps for mine dewatering, to dosing pumps for wastewater treatment, heap leaching, tailings thickening and flotation. We also supply submersible pumps and cantilever pumps for the removal of nuisance sump water.

Floor mop-up

Supply of submersible pumps or cantilever pumps for the removal of nuisance sump water

Flotation

Recovering of materials through the use of chemicals to alter the density of the liquid. Equipment is designed to be hard wearing, handling solids, and liquids of varying viscosities without reduction in flowrate.

Heap Leaching

Use of leached pulp and carbon for the recovery of precious metals from tailings. Precious metals are recovered by dissolving them by applying chemicals such as sulfuric acid onto ore or tailings. The metals are dissolved into leachate which is then recovered.

Tailings thickening

Dewatering of solids from tailings into a concentrated slurry using thickeners and filter presses. Water can then be recovered for reuse which is essential as mines are often located in isolated areas away from sources of water, and reuse of excess water also reduces large disposal costs from mines

Cyclone feed

Cyclones can be used to dewater slurries pumping water with a small chamber and through centrifugal force pushing solids to the outer walls to be drained away and removed. Our pumps can be ran according to your requirement via a Variable Frequency Drive ensuring the required feed rates are met without loss in process efficiency.

Mine dewatering

Removal of excess water from deep within the mine to the surface which can be via high pressure pumps mounted on a floating pontoon feeding another pump to reach the required surface level with liquids containing fibrous solids operating according to variable demand. Pumps can be oversized to accomodate large solids without reduction in flowrate, with equipment design to reach the top of the mine from the very bottom, or through multiple stages across levels in the mine. Read more about how we handled such a requirement in our mining case study.

Waste Water treatment

Hydrogen peroxide in Mine Water is used for the removal of cyanides from wastewater. It enables deeper leaching by direct oxidization when used as part of Gold leaching as it provides a chemical source of oxygen. It is also a good ferric ion recoverer and it can replace the use of ammonia as a precipitation agent in uranium mining.

Caro acid modules use a combination of hydrogen peroxide and sulphuric acid dosed continuously in a mixing tank to dose directly onto pulp and used as acid detoxifier to reduce cyanide levels to safe permissable levels. The combination can also be used for purification and recovery of valuable metals such as Vanadium and Tungsten from waste material / tailings and is known to be a good ferric ion recoverer.

We offer pumps with the following features to assist in the mining industry:

Variable speed drive pumps with large solids handling capacity

Low shear during leaching and slurry transfer ensuring solids remain in suspense But with maximum flow

Seal less pumps without valves ensuring blockages do not occur and ensuring the opportunity for seal wear is removed.

Hard wearing pumps specified for process longevity reducing downtime

Leakage sensors to warn if any volatile chemicals are leaking with pump casings

ATEX rated for the most volatile of atmospheres

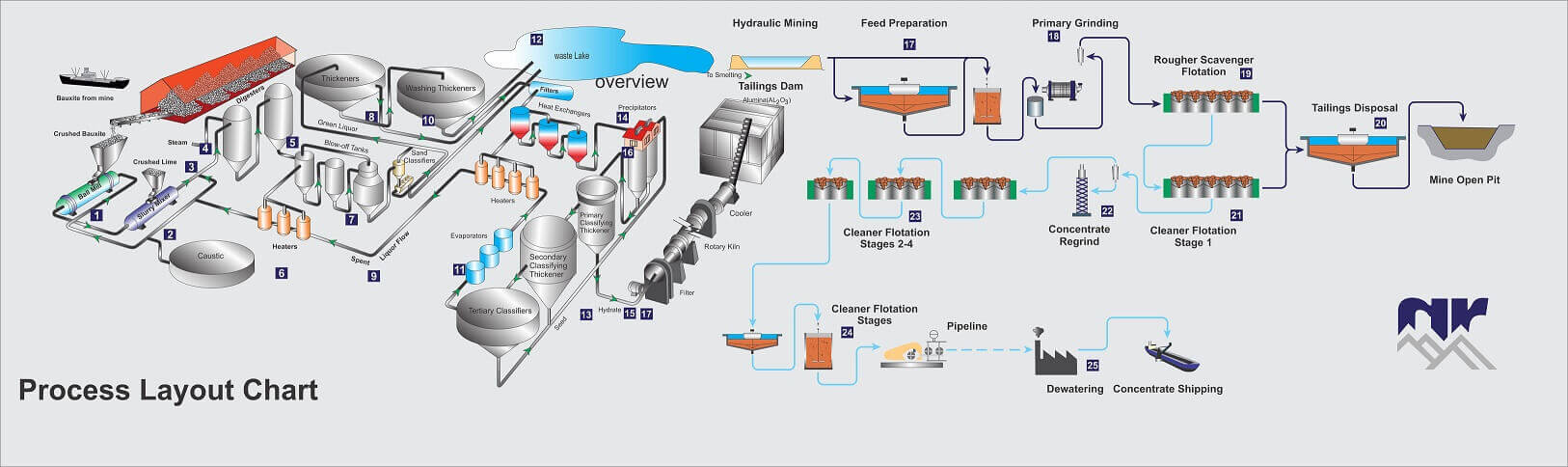

Download and Keep our Mining Industry Process Overview

Whatever your process within a mine, we will supply engineered pumps for your process. View our range of pumps for the Mining Industry