Paint, Print & Varnish

Paint is made up of 4 ingredients which are typically pigment, additives, resin and solvent or water.

What are pigments?

Pigments within paint are to provide the main colour, provide hiding of the object it adheres to. The main pigments used in paint are Titanium dioxide to provide brightness, whiteness and transparency, Zinc oxide which resists yellowing, UV light, and mildew and Titanium dioxide which provides whiteness and great hiding power. Fillers are a type of pigment and can be used to thicken the volume of paint and thicken film. Such fillers consist of inert materials such as clay or lime.

Pigments within paint are to provide the main colour, provide hiding of the object it adheres to. The main pigments used in paint are Titanium dioxide to provide brightness, whiteness and transparency, Zinc oxide which resists yellowing, UV light, and mildew and Titanium dioxide which provides whiteness and great hiding power. Fillers are a type of pigment and can be used to thicken the volume of paint and thicken film. Such fillers consist of inert materials such as clay or lime.

What are the additives?

Additives are included to change the consistency of paint, prevent foaming, skinning, improving flow characteristics and improve pigment stability.

What are Resins?

Resins bind ingredients such as pigments and additives of paint, durability and resistance such as for hard-wearing paints in high traffic areas of a house, moisture resistance when the paint is used in bathrooms and kitchens, UV resistance in direct sunlight such as in wood gloss.

What are solvents and water used for in paint?

Solvents and waters act as the carriers for paints which remain in the paint when within a container, but when painted are absorbed into the painted material to transfer paint into materials before evaporate leaving behind the paint.

Water-based Inks are environmentally friendly, and much easier to handle due to their low viscosity, and solubility within water making cleaning of mechanical equipment much easier.

Solvent-based paint is more viscous and difficult to convey when mixed with paint as well as being highly flammable. Solvent-based inks can be highly viscous and problematic to pump due to its nature to act as an adhesive when combined with resins and polyurethane. Such paints should be conveyed gently with a low shear motion.

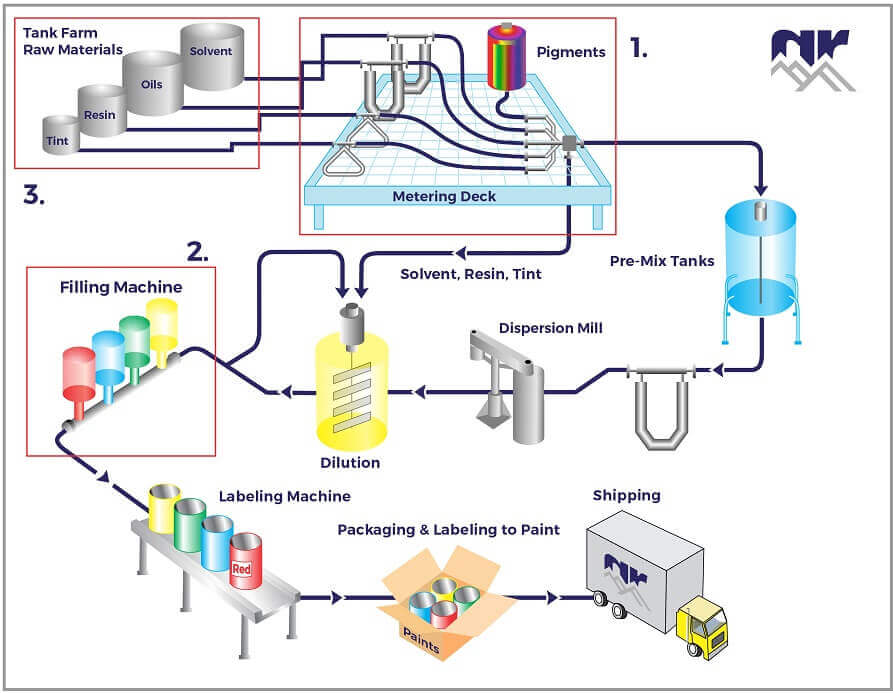

The paint manufacturing process begins with raw material and additives being mixed to provide an even base with solids suspended within the liquid. This mixture is then fed to a disperser to dissolve solids, disperse pigment throughout the paint, emulsify and ensure the mixture is consistent. Liquids can range from paste to fluids which can flow easily. Blending begins with resin and additive agents added to the milled base. During the colour phase ingredients are added until the liquid reaches the required colour. Filtering is then used to clean paint after which it is packed into containers.

The Pump types used to handle paint are peristaltic due to their low shear pumping motion, reversibility and ability to handle various viscosities. AOD Pumps are also used to due to their intrinsically safe nature being ATEX rated, Easy cleaning, ability to dismantle and low shear motion.

We provide pumps for the following paint applications:

Metering

Tank farms

Solids in suspension

Transfer

Dosed

Slurry transfer

Mixing

Dilution tank

Spraying

North Ridge Pumps' range of pumps for the Paint, Print and Varnish Industry