Wastewater Treatment Industry

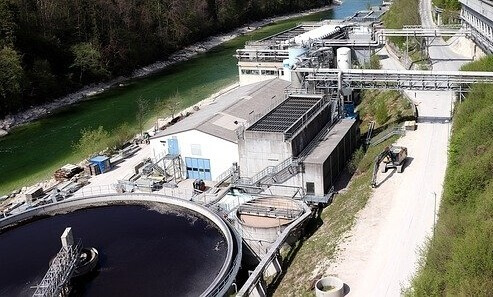

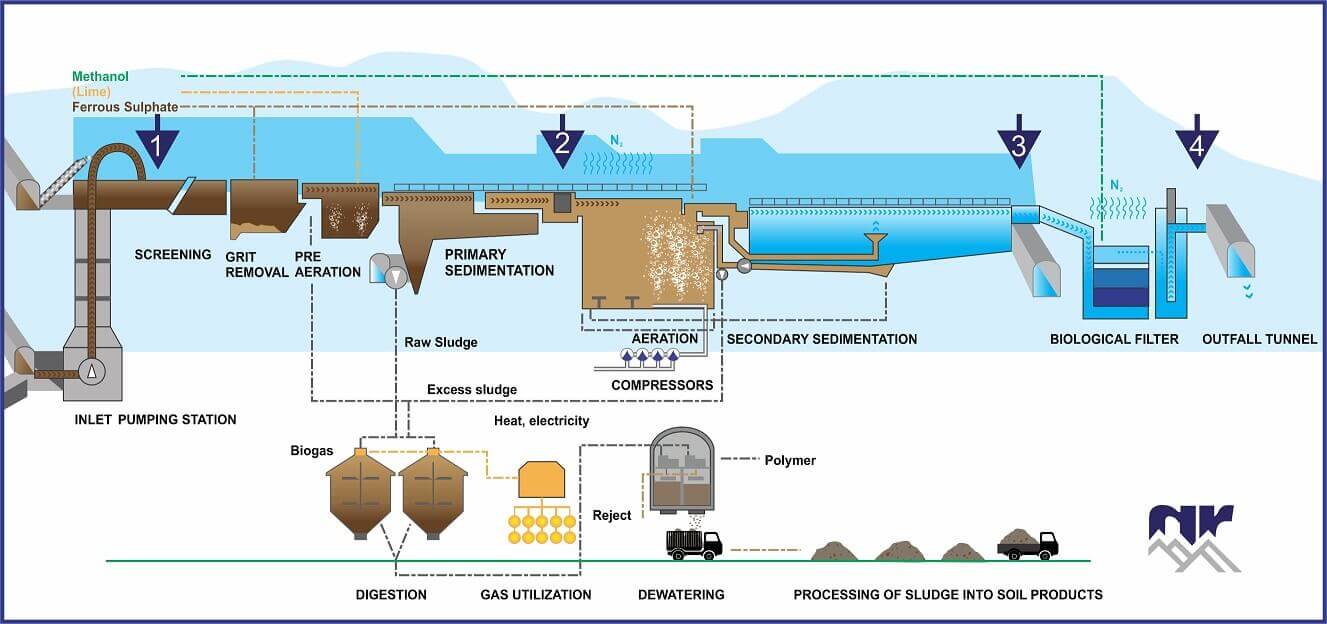

Wastewater is generated by industrial, domestic and municipal industries varying in contaminants and quality. The process for treating waste water involves different treatment stages depending on its originating source.

Wastewater is often generated in large amounts from industrial processes and is required to meet certain criteria before discharge into drainage networks or rivers as it can contain traces of heavy metals, fibrous substances, chemicals and small solids particles.

Similarly used water from food manufacturing plants can affect Biological Oxygen Demand and Chemical Oxygen Demand with starches dissolved within the water which if discharged can lead to low dissolved oxygen levels available for aquatic organisms such as fish and insects causing them to die.

Industrial plants will often have to monitor water quality before discharge through the use of a water quality monitoring system with dosing pumps treating water ensuring it meets a particular PH level before being able to discharge into mains pipework or rivers.

Wastewater from municipal processes is often one of the forms of water which requires the least treatment as it contains water from surface run off, dewatering of culverts and excess water from effluent treatment processes which is less aggressive than industrial wastewater and requires a lower grade of material choice and treatment.

There are three stages of wastewater treatment primary, secondary and tertiary. Primary treatment involves water flowing into a settling tank or clarifier allowing solids to separate by density with lighter solids floating and heavier sinking. The particles which sink form a sludge which are removed using mechanical means, dewatered and removed. Such sludge is referred to as cake.

Secondary treatment involves the additional treatment of water through the use of biological matter and water borne microoragnisms to treat the water. Extra process such as aeration may be used to accelerate biological breakdown and filtration to remove sediment further. These processes treat water and contaminants to safe levels.

Tertiary wastewater treatment further treats water to safe levels for home or industrial use with microscopic filtration and biological treatment. Chemicals may be added and before being discharged into main water courses the fluid must meet certain regulatory standards.

Contaminated wastewater and sewage are handled using centrifugal pumps with an open or closed impeller ensuring high flow rates and relatively low pressures.

Dosing pumps are used for treating water to a specific PH before discharge into mains pipework which can be diaphragm metering pumps, progressing cavity or peristaltic pumps.

Coagulants and flocculants are used in wastewater treatment plants for the removal of solids and part of the secondary and tertiary stage of water treatment. Coagulation is used to coagulate solids or group solids together rather than be dispersed in a liquid. Flocculation is then used to make the grouped solids sink to allow separation of the water from suspended particles.

Coagulants and flocculants are used in wastewater treatment plants for the removal of solids and part of the secondary and tertiary stage of water treatment. Coagulation is used to coagulate solids or group solids together rather than be dispersed in a liquid. Flocculation is then used to make the grouped solids sink to allow separation of the water from suspended particles.

Flocculants and coagulants are shear sensitive and so a slow pumping motion is required to ensure they are not damaged.

Variable Speed (VSD) pumps are used to accommodate different treatment rates which can vary during spring algae blooms, and differing levels of process activity. Pumps can also be designed for 24/7 running to ensure flocculant is kept in suspension when not being dosed.

As demand can be variable pumps can be VFD driven to allow multiple duty points, and fitted with casing wear rings to improve life span as the wear rings wear as opposed to the casing.

Download and Keep our North Ridge Waste Water Process Overview