Renewable Energy Industry

Renewable energy usage within the UK accounted for 15% of electricity generated in the UK in 2017, with targets of 20% by 2020 and 32% by 2030 large scale investment is needed within renewable generation technologies in order to deliver the required increase.

Renewable energy is produced by utilising Solar, Wind, Biological and hydroelectric technologies to generate electricity. Each method generates electricity or heat in a different way, meaning the processes pumps are involved in varies.

Below is an overview of where pumps are used within each industry:

Wind

Pumps are utilised within the wind industry for gearbox lubrication within the turbine itself, for the spraying of turbine blades to clean residue from them. In floating, wind installations pumps are also utilised for the stabilisation of the turbine itself as ballast pumps moving seawater around tanks to ensure the turbine remains level.

Diesel turbines are used to generate power for essential services, to energise the offshore substation and during low wind, can provide backup power as a reserve.

Pumped Hydro

Pumps as turbines are a viable alternative to hydroelectric schemes in installations between 7.5Kw and 1000Kw. Pumps as turbines (PAT) is a known concept of using excess flow and pressure to operate pumps in reverse to generate electricity. PAT has twin modes to enable them to pump as well as generate electricity. Water is typically pumped up to a higher area such as an upper reservoir during periods of low energy cost, and when energy costs are higher a valve is opened draining the reservoir forcing flow through the pump generating power.

Pumps as Turbines can operate in one direction if required where power is generated consistently from a fast-flowing stream such as a river. They are much easier to service and maintain as they contain fewer parts, are less complicated in design and cheaper to repair during planned maintenance.

Solar Panel

Pumps are utilised in various ways within the solar industry. Borehole Pumps in remote areas are operated by solar to extract water from aquifers and groundwater via boreholes. We recommend our range of borehole pumps for such purposes which are fitted with 3 phase motors as opposed to 12/24v motors as they are far easier to service locally in remote areas. Dc motors are very difficult to maintain where local expertise is not available and can often involve the motor being replaced rather than serviced in situ. The motor is driven by an inverter which converts DC power to 3 phase.

Solar-powered pumps are utilised for Irrigation of crops and fields, as well as providing drinking water. Horizontal centrifugal pumps which are utilised for drinking water may operate via a DC motor during low light conditions. If DC pumps are not viable battery back up panels can provide the required energy to drive single-phase and some three-phase motors.

Pumps utilised for cleaning to keep solar panels to maintain efficiency ensuring maximum output.

Tidal

Tidal energy involves the generation of electricity by tidal energy causing either pistons to rise up and down, or turbines to rotate. In large scale installations cooling, large transformers are required meaning external cooling is required which is provided by cooling pumps.

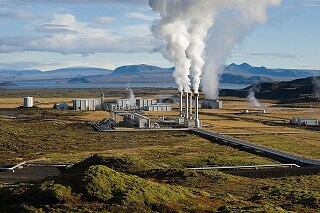

Geothermal

Geothermal involves the abstraction of heat from energy stored in rocks deep underground, which radiates to the surrounding area heating water in underground reservoirs.

This heated water can be utilised in various ways to generate heat or power:

Dry Steam - This is the most popular method where hot steam is pumped into a turbine to generate power. The condensate is then reinjected back into the well.

Binary - The water and steam are kept separate with the hot water from the reservoir heating water from another source via a heat exchanger. This generates steam which rotates a turbine generating power.

Flash Steam -Hot water is pumped into a low pressure and cooler tank with the sudden change in temperature and condensate powering a generator.

Closed Loop - Underground pipes recirculate liquid within a closed system which heats fluid pumped around buildings via heat exchangers.

Open Loop - Water is taken from an open body of water, fed into a heat pump and then discharged to the atmosphere.

As the liquids being pumped can be at high temperatures, high casing pressures, contain dissolved metals which have leached from surrounding rocks as well as being of brine like nature it is important to close attention is made to material selection to ensure the longevity of the process.

We offer pumps with the following features to incorporate within any renewable energy process:

AC/DC Drive

Inverter driven borehole pumps utilising easily serviceable 3 phase motors driven by DC supplyMaterials suitable for corrosive brine containing dissolved metals at high pressures and temperatures

Efficient design ensuring low energy usage

Inverter driven to enable one pump to deliver a multitude of duty points.