Rubber & Plastics

Manufacturers within the rubber and plastic industry share similar manufacturing processes. They are categorised within the same industry not only because of their similarities in manufacture but also but due to the products being interchangeable with rubber parts being substituted for plastic which is often cheaper, lighter and through the use of thermoplastic polyurethanes have enhanced chemical resistance.

Plastic and Rubber can be manufactured in a number of ways:

Injection – Rubber and Plastic

In injection moulding resin pellets or rubber is melted inside a heating chamber within an injection machine. The plastic or rubber is then pumped into a mould which results in a solid plastic or rubber part. After forming the desired shape rubber must be vulcanized where it is heated to approximately 140°C – 180°C with sulfur added with carbon or zinc to improve the rubber qualities.

Extrusion – Rubber and Plastic

With extrusion which is similar to injection, plastic or rubber is melted within a heating chamber then pressed through a die giving the plastic or rubber a particular shape. The rubber is then vulcanized.

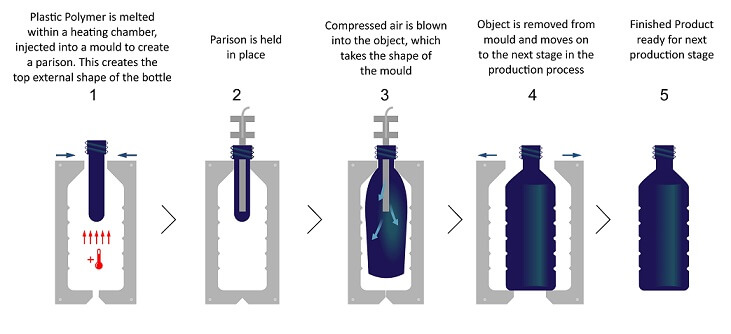

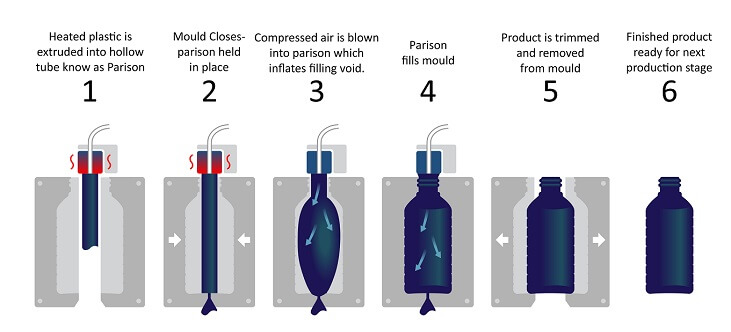

Blow Moulding – Plastic

This is where hollow pre-shaped plastic pieces in thermoplastic to a particular length known as a parison has a mould pressed around it. Air pressure is applied which forces the parison to assume the shape of the structure, with the piece remaining hollow. Parisons can also be injection moulded or extruded and an example of this is in bottle manufacture above.

Rotational Mould - Plastic

During a rotational mould process plastic is pumped into a frame which is then sealed, melted and rotated until coated entirely in plastic with the interior of the piece hollow.

Latex Dipping – Rubber

Thin-walled moulds are immersed in latex before being slowly removed. The time immersed in latex has a direct correlation to the product thickness. After dipping the rubber requires vulcanizing to harden.

Moulding – Rubber

Rubber due to its softness can be compression moulded. Another way of shaping rubber is by pumping into an already warm to accelerate the sculpting process.

Calendaring – Rubber

In order to create rubber sheets to a required thickness, rubber is subject to a process known as calendaring where it is fed between 2 metal rollers which compress the rubber, only allowing rubber of a particular thickness through the rollers.

In all of the above processes within rubber and plastic processing, thermal oils are used as a heat transfer medium during polymerization, polycondensation, and synthetic fibre processing such as nylon, and polyester. Thermal oils are used for drying, bonding but are also used for barrel cooling during blow moulding.

The applications we can provide pumps for include:

Mould filling

Latex recirculation within dipping tanks

Transfer and natural packaging

Latex metering to forming operation for injection moulding

Metering of liquids for blending

Extrusion during 2 part solution

Adhesive metering

Reactor discharge/ emptying

Monomer/emulsifier solvent metering

Thermal oil pumps

We can assist users in the rubber and plastics industry with the following pump features:

Low shear pumps ensuring the consistency of rubbers and plastic is not changed

Pumps with heating jackets to maintain product temperature

Metering pumps for the precise delivery of plastic or rubber

Seal less pumps to ensure there is no air ingress which can change the consistency of latex pumps which are reversible to clear pipework and ensure all product can be removed without solidification