Surface Treatment Industry

Surface treatment involves the application, coating and removal of finishes to metals. A surface treatment process consists of multiple separate stages consisting of separate baths of non-metallic construction which contain fluids for a specific stage in the process. Surface treatment can be used during the recycling of metals but also when metals are required to a particular finish, standard or colour.

Not all metals will follow the same step by step process during treatment, an outline of the various treatment stages are detailed below:

Degreasing

The first stage of treatment of metals is usually a degreasing stage. Degreasing involves the use of petroleum, chlorine or alcohol solvent to dissolve machining fluids and any impurities such as dust which may be present on the surface of the metal after production and during storage or handling. It is important to de-grease the surface to ensure any coatings applied are uniform in the finish without the presence of bubbles, differing levels or absence of coating which can happen if contaminants are present.

Etching or Picking

Etching or picking involves the use of strong acids such as hydrochloric and sulfuric acid to clean metals by removing the surface layer of metal. This can be to remove oxides or heat tint, and achieve a uniform finish if not already achieved during production. it can also be used to apply graphics through chemical etching. Some times metals need to be etched to descale removing limescale if the metal is used in contact with a heating element and hard water. An example of this is inside a kettle.

Bating

Bating is the use of enzymes or proteins in an aqueous solution to remove proteins and soften the material. These can be a process in tannery’s to soften leather but also with other materials such as the softening of animal skins.

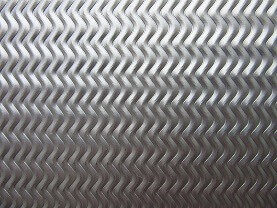

Galvanic Coating

Galvanising is the process whereby a coating is applied such as Zinc or aluminium to protect and prolong the life of another material such as cast iron by being impermeable providing a protective layer sealing pores. A galvanic coating can be applied through one of three ways. The item can be dipped in hot liquid metal (hot-dip), electroplated within a bath, or coated through thermal diffusion whereby the item to be coated is heated to between 320°C and 390°C with a galvanic coating such as zinc applied in powder form which melts onto the item.

Electroplating and Electrolyte Coating

Electroplating and Electrolyte coating is used to apply a thin layer of metal such as Nickel, Chrome, silver, Gold, Rhodium, Zinc, Copper and Chromium to another material. It can be applied to improve another metals appearance for example in chrome plating of parts, improve the corrosion resistance of another material, improve paint adhesion, and used in the printing circuit boards.

Electroplating works by a current being ran through a plating bath containing an electrolyte solution and the item which requires coating with metal. The item is negatively charged (cathode) which is placed in a circuit with the material which will coat it (anode). The cathode attracts ions from the anode which brings particles of the material with it coating the desired item with a thin layer.

Antiozonants

Antizonants are used as additives during manufacture to prolong the life of rubbers. They consist of chemicals or waxes which surface on a rubber material to protect it from attack from its environment.

Anodising / Anodic Treatment

Anodising is a process used during aluminium treatment where aluminium is immersed within an electrolytic solution and sulphuric acid to create an aluminium oxide layer or barrier layer to enhance aluminium’s environmental resistance. Through the use of hard anodising aluminium’s wear resistance can be increased.

Electrocolouring

Colouring of aluminium through the application of organic dye solutions as anodising leaves microscopic pores allowing the aluminium to absorb dyes when immersed.

Sealing

After Anodising the pores of aluminium remain open. There are two methods of sealing metals after anodising. One is through hydration which involves the application of deionised water or steam to seal pores. The other is known as impregnation where deionised water or steam in conjunction with mineral salts closes pores within the metal.

Rinsing & Neutralising

Two important steps which can occur during surface treatment repeatedly include rinsing and neutralising. Rinsing is used to remove the possibility of cross-contamination from a previous process step and neutralising removes any traces of previous solutions by neutralising the last chemical used. Typical fluids used are deionised water which is water-free from minerals ensuring streak-free surface finish as well as ensuring contaminants are not introduced to the surface.

Phosphate Coating

Phosphate coating is applied to ferrous metals such as steel to prevent corrosion. A steels surface can be coated with iron phosphate through immersion in phosphoric acid. Zinc phosphate coatings are applied through spraying.

Given the chemicals used in surface treatment which can be expensive, hazardous and toxic it is important any pumps specified are safe, transfer liquids without splashing, can handle solids if required and run continuously when ran in recirculation.

North Ridge Pumps provide the guidance to ensure the correct pump is chosen for the desired application within surface treatment, ensuring safety and longevity through pump design. View our Pumps for the Surface Treatment Industry