Tanker Unloading of Toxic Chemicals

Considerations For Tanker Unloading of Toxic Chemicals

Tanker unloading is an application that requires careful consideration due to the low NPSH requirements of some fluids transported within the vessel. The chemicals are kept under pressure to ensure they remain as a fluid, as when exposed to atmospheric temperature there is a high risk they can boil as such fluids often have low boiling temperatures -some times lower than room temperature meaning they are kept under high pressures to keep them as a fluid.

We were contacted by a customer that needed to empty several tankers containing many variations of toxic and flammable liquids, including; propane, butane and toluene. They had two main concerns, firstly the flammability of the fluids, and secondly ensuring no product leaked due to their toxic nature.

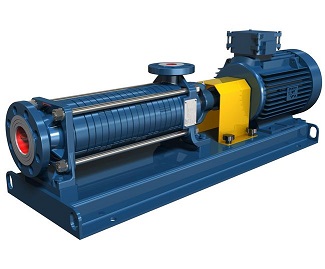

Our Atex NRSC Side Channel Pump in Stainless Steel 316 for Low NPSH Requirements

Due to the Atex, no leakage and low NPSH requirements, we selected several of our NRSC Side Channel Pumps in Stainless steel 316. Due to their special design, our side channel pumps can operate with as little as 0.35 metres of NPSH available, and can handle up to 50% entrained gas content. These pumps were fitted with magnetic drive couplings that ensure zero chance of leakage. ATEX rated motors were also fitted due to the flammability of the fluids being pumped.

Controlled tanker unloading with pumps is increasingly becoming the preferred method of tanker unloading, as opposed to pressurizing the tanker with compressed air to remove contents by “blowing”. The utilization of side-channel pumps not only increases the recovery rate of chemicals from tankers, meaning wastage is lowered, it also ensures savings are made by the ability to completely empty the tankers. The ability to fully empty the tankers negates the risk of any excess product having to be returned to the supplier who will then charge for disposal.

Below are the specifications of the 6 pumps that were supplied:

Model: | |

Materials: | Stainless steel 316 |

Flow rate: | 12m³/hr |

Head: | 40m |

Motor: | 2.2Kw, 1450RPM |