What are Pump Couplings

What are Pump Couplings?

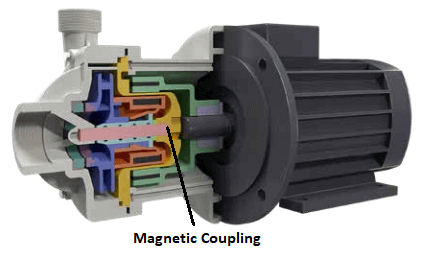

Couplings also known as shaft couplings are used to connect the rotating pump shaft with the drive shaft of the motor ensuring torque is transferred to the pump with minimal losses.

Couplings are typically aligned by laser alignment but can also be aligned by the use of a straight edge and feeler gauge. Couplings must be aligned within a specific tolerance as any misalignment will cause premature failure of rotating parts due to extra stresses being placed on parts.

There are 3 types of coupling misalignment which are axial, radial and angular.

Axial

Coupling components are not joined at correct set distances leading to ineffective transmission of power leading to wear and damage to rubber spider elements or if too close the rubber flexibility is compromised leading to excess wear.

Radial

This is where shafts join together and the centre line is at different positions meaning one shaft is higher than the other.

Angular

This is where the shafts and couplings are at different angles to each other.

Symptoms of misalignment include excess wear on coupling parts, vibrations, high bearing wear and lower seal life.

There are three types of pump couplings which are rigid, flexible and magnetic. The below table outlines the differences between the three types:

Couplings are typically selected based on a multitude of factors based on pump application, duty point, running time and if you are experiencing excessive coupling wear or failure your pumping process may need a review.

Please contact our technical team to discuss any issues you are experiencing, and how we can solve these.