Low NPSH Pumps Guide

In order for a centrifugal pump to deliver a specific discharge flow, it must have sufficient suction pressure known as NPSHR.

Without sufficient suction pressure, a pump will suffer from cavitation leading to internal damage and produce less flow.

Cavitation is where fluid at a pump's inlet begins to vaporise. Small bubbles form within the liquid which then collapse onto wearing parts transferring large amounts of destructive energy causing a pitting effect and for parts to appear as though they have suffered from severe corrosion.

When cavitation occurs the discharge flow can drop and there is a noticeable sound similar to that of ball bearings or gravel passing through a pump.

With excessive cavitation, vapour locking can occur where the fluid becomes mostly a vapour which can be difficult for a pump to recover from as it continues to generate heat and vaporise increasing amounts of fluid. Cavitation can cause rapid failure of a mechanical seal, casings and impellers.

What is NPSH?

When a liquid is in fluid form it possesses energy above than that what is required to maintain it as a liquid. All liquids have a vapour pressure which is the temperature at which the liquid will begin to change into a vapour/gas at atmospheric pressure. What can happen in cavitation is that the suction pressure can reduce to such an extent that fluid reaches its vapour pressure boiling at the pump inlet. Steps must be taken to ensure this does not happen and the fluid remains a liquid. Whenever NPSH is discussed there are usually two separate definitions which are discussed – NPSHA and NPSHR.

NPSHA

This is the NPSH Available in the system measured in M or feet. The pump must meet this figure in order to deliver the required duty point.

NPSHR

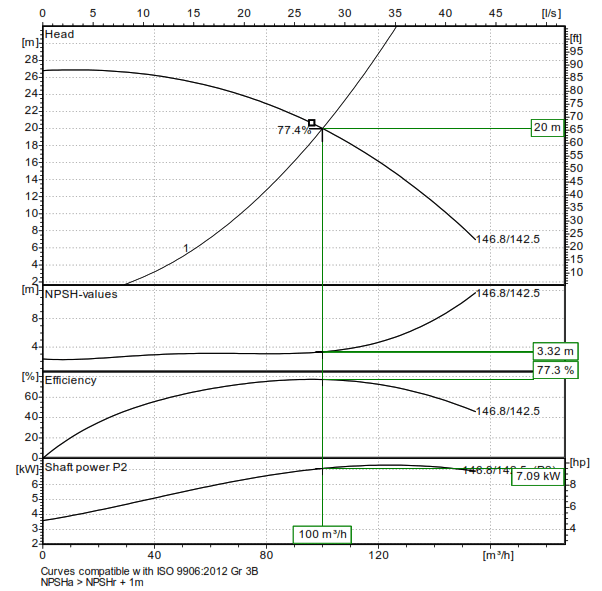

This is the NPSH required by the pump in order to meet the duty point and deliver the required flow and pressure. In the below curve for the duty of 100M³H at 20M Head to be met an NPSHR of 3.32M is required. The NPSHA should always be more than the NPSHR with at least a 10% margin to allow for pump wear, and as a tolerance between theoretical calculations and actual loses produced by the system. As you can see the NPSH Required increases sharply as the pump reaches the end of the curve where the pump will begin to cavitate. Read more about where a pump should operate on its curve.

6 Causes of Low NPSHA leading to Cavitation

High flow – causing a greater velocity increase into the impeller eye and higher pressure drop at the pump inlet

Low flow – increase in temperature of fluid due to energy being transferred from impeller and friction from the casing as well as circulation flow from wear rings

Suction pressure – low suction pressure caused by system design or clogged inlet filter or air ingress

Unexpected heating of pumped fluid meaning NPSH A reduced

Pump wear due to increasing in tolerances between parts causing increased impeller flow and circulation. A pumps NPSHR may increase by 50% due to a doubling of wear ring clearances

Parallel flow – mismatching of pumps connected to common suction manifold where one pump suffers from increased pump wear with one pump taking a higher proportion of the flow.

Npshr should always have tolerance and be monitored in low NPSH conditions. It is possible to reduce the NPSH of a pump by up to 50-60% of the original level by fitting an inducer to the pump inlet but this would only reduce the npsh required at certain sections on the curve and not across the whole pump curve.

The NPSH value quoted on any diagram is usually based on a 3% pressure decrease at full impeller diameter. The NPSH available must exceed the NPSHA by at least 0.5m to 1m.

Download and read at your convenience our Infographic on the 6 Causes of Low NPSHA

Do you require a low NPSH pump? Contact us today to discuss more.