Progressive Cavity Pumps vs Incline Conveyors For Residual Sludge Guide

Progressive cavity pumps are a viable alternative for conveyors. With long service intervals Progressing cavity pumps can handle up to 45% dried solids making them a strong contender for use in dewatered sludge and cake transfer.

With service intervals up to 20,000 hours when installing correctly they can provide the required sludge handling capability easily between plant shutdowns.

Choosing a progressing cavity pump to transfer sludge from a centrifuge means lower energy usage and can expect to save 4-5 kW per hour of usage which can lead to substantial savings in particular when being used for 24 hours a day.

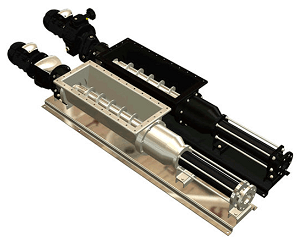

Progressing cavity pumps can be fitted with screw conveyors as well as bridge breakers ensuring the sludge does not clog the pump inlet.

PC pumps have a large number of combinations of rotors and stators to match flocculent being used, which can change several times during a plants lifetime.

The fluid contact parts can be replaced within a couple of hours if required and are fairly straight forward once tie bolts are removed vs a conveyor in which if a liner needs replacing the time taken to do this can be extensive given the number of bolts per section.

PC Pumps offer a way to fully containerize a sludge handling system which can suffer from odour issues in particular within warm climates and temperatures. One issue with conveyors is that during periods of high volume processing sludge can spill from conveyors causing secondary odour issues. Oversized hoppers can be manufactured to connect to pipework ensuring high processing capability which also reduces the likelihood of them running dry.

Accessories such as product sensors can ensure the pump only runs when required and with a VFD the pump can be run according to required demand.

Accessories such as product sensors can ensure the pump only runs when required and with a VFD the pump can be run according to required demand.

If you are thinking of using a conveyor for residual sludge speak to us to determine whether a progressing cavity pump will be lower maintenance and long term cost-effective solution when all factors have been considered.