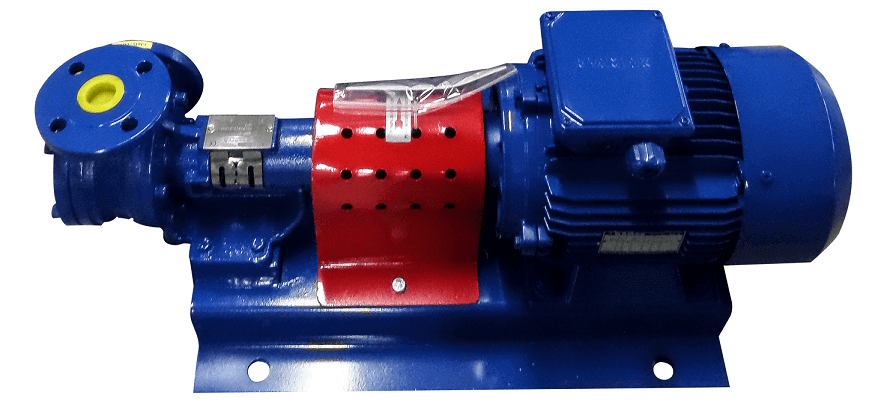

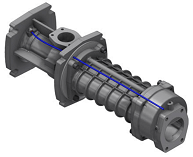

Screw Pumps vs Gear Pumps Guide

Screw Pumps and gear pumps utilize the same pumping technology and are from the same pumping family of positive displacement pumps.

They are chosen as a solution for the transfer of viscous fluids which require transfer with both having different advantages and disadvantages.

Sometimes both pumps can be selected for the same application but why choose one pump technology over another?

To enable an easy comparison to be made we have constructed the below table showing the various features between both pumps:

| Screw Pumps | Gear Pumps |

| Advantages | Advantages |

| Operate at full motor speed (2900rpm / 3600rpm) meaning non-pulsating flow and no requirement for a gearbox | Internal parts are usually cheaper |

| Higher pump efficiency as mechanical efficiencies are not lost through the gearbox | Higher range of viscosity handling |

| Smaller footprint as the gearbox is not required | |

| Disadvantages | Disadvantages |

| Limited viscosity handling | Bushes and bearings located in pumped liquid meaning parts are subject to wear / damage from fluid being pumped |

As screws wear, a full set of screws should be replaced at the same time to ensure pump functions correctly | Noisy pump due to the presence of gearbox, and pumping technology utilizing large gears meaning turbulent flow is created causing larger vibrations and lower working life |

| Can not handle solids | |

| Pulsating flow due to low RPM and large gears | |

Less efficient meaning for the same duty as screw pump a larger motor is required | |

Gear pumps are unable to operate a high RPMs due to the design of gears and teeth meaning larger pulsations in the discharge pipework requiring a pulsation dampener. |

If you require pumps for a viscous fluid and are looking for technical advice as to the best solution, please contact us to enable us to select the most appropriate pump for your application.