What Are Lobe Pumps?

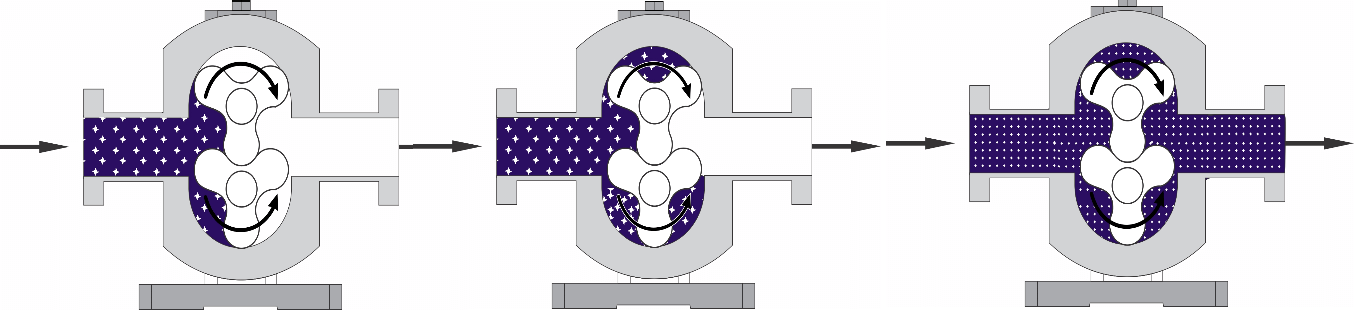

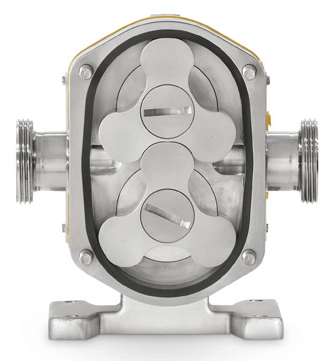

Lobe pumps are similar to gear pumps in that the pump operates by two Y or I shaped lobes which are aligned vertically rotating within a pump casing. The timing is controlled via a gearbox and timing gear which prevents the lobes from making contact with each other ensuring they rotate 90° out of phase.

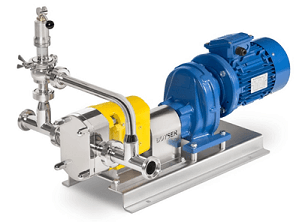

In rubber lobed pump designs, the lobes rotating within the pump casing create a vacuum enabling the pump to be self-priming up to 6M as well as handling gas slugs. Metal lobed pumps require a flooded suction. Inlet & outlets on the pump can be configured horizontally or vertically.

The lobes create flow by creating exposed cavities for the liquid to flow into which are then rotated towards the outside of the pump casing and expelled through the outlet of the pump. Liquids do not pass between the lobes and pass through the outlet ports.

Why are lobe Pumps used?

Lobe pumps are chosen due to the low speeds they can be operated at between 20-1200rpm ensuring liquids are handled in a gentle slow-motion preventing their consistency from being changed. They handle between 1cst and 55,000 CST, and produce flows up to 300M³H, while handling liquids up to 150°C.

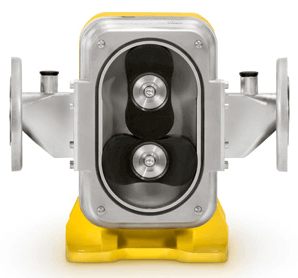

Lobes can be manufactured from Stainless Steel AISI316 which are hygienic rated and of sanitary design, but can also be rubber for use in industrial applications. Rubber Lobed pumps are self priming up to 6M as the rubber parts create an airtight seal, which is not possible with Metallic lobes. Metallic & Rubber lobes can be in tri (Y) or twin (I) lobed design, with all materials being able to operate in reverse.

The pump is sealed via a mechanical seal, double mechanical seal, packed gland or lipped seal. Heating Jackets can be fitted to ensure stable liquid temperature, and a bypass valve can be fitted on the front cover or externally to help prevent overpressurisation. Lobe pumps can be operated in both directions but a relief valve will only operate in one direction.

Units can be made suitable for dry running providing a lubricated seal system to the shaft seal preventing overheating.

This design of pump are easy to maintain given the front casing design. The casing can be opened easily through the undoing of four bolts, and inner parts and seals can be replaced within minutes. A seperate chamber between the gearbox and pump housing ensures should a seal failure occur in either the pump or gearbox that the two liquids do not interact.

Pump heads can contain wear plates to prevent the accelerated wear of the pump casing during the handling of solid laden sludges, or hard particles and which also enable low cost overhaul. This ensures cost effective maintenance of the unit throughout its life.

Applications include the handling of viscous liquids, which can contain solids up to 50mm, and gas slugs such as for the transferring of waste water sludge containing high percentages of dry solids.

They are therefore used in the following industries & Applications:

Food: Wine, Olive Oil, Vegetable Oil, Molasses, Pressed Olive Waste, Fermented Grapes, Glucose, Tomato Concentrate, Chocolate.

Industrial: Sludge, Slurries, Manure, Effluent, Crude Oil, Glue, Inks, Paint, Fuel oil,

Mining: Bentonite, Ceramic Slips, Calcium Carbonate.

Oil & Gas: Seawater, Crude-Oil products, Oily Sludge, Marine spills, Mud.

Pharmaceutical: Detergents, Surfactants, Glycerine

Wastewater: Membrane Bioreactor Filtration (MBR), Effluent, Sewage,

A comparison Table between Lobe, Flexible Impeller, Progressing Cavity, Gear, Screw and Centrifugal Pumps

Lobe Pump | Flexible Impeller | Peristaltic | Vane | Progressing Cavity | Gear | Screw | Centrifugal | |

Viscosity | 55,000 cst | 50,000cst | 50,000cst | 10,000cst | 1,000,000cst | 55,000cst | 15,000cst | 400cst |

Flow Rate | 300M³H | 72M³H | 72m³h | 110M³H | 600M³H | 200M³H | 1200M³H | 1500M3h |

Pressure | 10bar | 4 Bar | 15bar | 10bar | 48 bar | 14bar | 40bar | 50bar |

Solid Handling ability | High (without damage) | High (without Damage) | Low (with Small damage) | None | High | Low | Low | Low |

Priming ability | Low | High | High | High | High | High | High | medium |

Pulsation | Low | Low | High | Low | Low | Low | Low | Low |

Shear | Low | Low | Low | Low | Low | Low | High | High |

Accessories

A wide range of accessories are available to customise designs for your process. These include:

Custom inlet & Outlet Connections - Gooseneck connections are available ensuring the pump suction port remains fully filled with fluid. This ensures a vacuum can be created more easily, even should the lobes become heavily worn. Gooseneck pipework also ensures the conveying of gas bubbles which may form within a liquid.

Vertical outlet connections allow pumps to remain compact in design. Connections can be flanged, or according to hygienic / pharmaceutical requirements for speed of cleaning or removal from pipework.

Pressure Control – Units can be fitted with a Pressure Switch preventing pump operation at pressures likely to damage the system or pump. Alternatively, a torque limiter detects when the working action of the pump becomes strenuous preventing the pump from generating excess pressure. They can also be used to prevent pumps from dry running.

Bypass – If pressure control is undesired, units can be configured with bypass valve pipework connected to pumps, allowing fluid to recirculate back to the pump inlet should pipework become blocked. A bypass valve can also be connected on the front pump casing.

Lobe Protection - Sludge Screen, macerator or stone trap should be utilised in sewage sludge applications to preserve lobe lifespan

Heating Jacket - Heating jackets can be installed on the front casing allowing liquid temperature to be maintained and prevent solidification of material within the pump

Modular Configuration - Units can be baseplate mounted, mounted on trolleys allowing portability and complete with control panels allowing easy control of flow.

Modular Configuration - Units can be baseplate mounted, mounted on trolleys allowing portability and complete with control panels allowing easy control of flow.

Hopper with auger feed screw - allowing the pumping of high quantities of suspended solids, and ensuring fluids are fed into the pump for transfer.

Drive Options – Motors are available with dual frequency, or hydraulic drive to accommodate most drive requirements.

FAQS

The mechanical seal requires lubrication and cooling while the pump is operating. Without the presence of fluid, the mechanical seal will overheat and crack, and this may cause the pump to leak and fluid to enter the motor. There is also the possibility that the motor will burn out.

The rubber lobes may also melt or deform even after short periods of dry running.

Our advice is to ensure that the pump always has access to fluid while running, the vessel or sump on the inlet side of the pump must never run out of fluid while the pump is active.

Level sensors or a float switch can be installed in the fluid chamber ensuring that the pump is turned off in the event there is no fluid. Another way of protecting the pump is to fit a dry running device, this will turn the pump off if it detects that no fluid is entering the pump. If you think that dry running is inevitable, then please speak to us and we will select the most appreciate pump and sealing system for you.