What Are Side Channel Pumps?

Side channel pumps are a type of pump which is not well known. It is a type of design which enables pressures of 5- 10 times to be produced more per stage than normal impellers operating at the same speed found in multistage pumps.

This enables fluids of low viscosity to be transferred at high pressure and low flows but also benefit from the design being self-priming as well as handle entrained gas.

What is a side channel pump?

A side channel pump, also known as liquid ring pump is a type of self-priming multistage pump, having characteristics of that of a positive displacement pump.

Side Channel pumps are quite unique in terms that they can handle up to 50% of entrained gas with fluid and vapour taking different paths through the pump. They contain multiple impellers similar to a multistage pump, however the design of the impellers are slightly different being more like a multistage peripheral pump.

How does a side channel pump work?

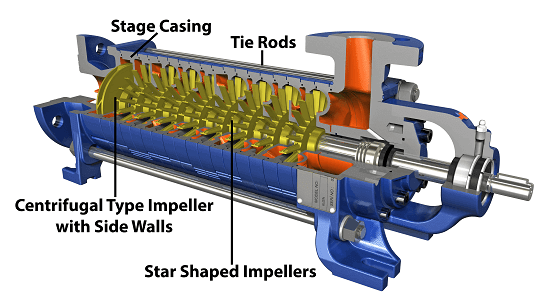

Units contain multiple radial vane designed impellers with some models having the first impeller of closed design similar to a centrifugal pump having contains side walls. The pump looks similar to a multistage pump with each impeller housed within a stage casing held together by tie rods.

The fluid path enters the pumps inlet, where it comes into contact with a suction stage casing. It then passes through impeller vanes before exiting via the outlet port where it enters another ring section repeating the same process or exits the pump through the discharge.

The vapour path enters the pump inlet, and passes through the suction stage casing similar to fluid, before passing around the outside of the impeller and exiting via a secondary discharge port.

Advantages of a Liquid Ring Pump

There are many advantages to a liquid ring pump due to its unique design:

1. Lower System Costs – As the pump accepts inlet heads of less than 0.5M of boiling liquids, it is less sensitive to cavitation and accepts NPSH values as low as 20cm meaning less system infrastructure is required. Higher pressures can be achieved by smaller motor powers, and with smaller unit sizes than multistage pumps.

2. Self-Priming – Pumps are self-priming by design enabling units to be mounted on top of tanks, which can be safer saving on secondary bunding, also eliminating the need for secondary priming devices. When container emptying, due to its design the unit retains fluid meaning re-priming is not necessary.

3. Entrained gas handling -meaning the pump can handle pumps with high gas content such as condensate, but also handle a mixture of liquid and air enabling the pump to completely empty containers, handling liquids with gas slugs problem free.

4. Low NPSH requirements – With liquids which are being pumped close to their boiling point such as liquid CO2, Liquid Petroleum Gas (LPG), liquid ammonia, Liquid Hydrogen, refrigerants and other hydrocarbons, a pump with a low NPSH must be selected otherwise the fluid will boil at the pump inlet potentially causing gas locking within the pump.

Side channel pumps have a NPSH as low as 0.2M meaning such problematic fluids can be handled without issue. Furthermore the amount of fluid which can be extracted from containers is far higher than if a standard centrifugal or vane pump was used.

Certain models are known to be cavitation proof pumps, due to their low NPSH but also in applications with variable vapor pressure involving gaseous liquids.

5. Problem Free Pumping –Volatile chemicals such as aerosols, liquified gas, hydrocarbons or refrigerants with varying inlet pressures can be pumped problem free due to the design of pumps. Units can be built with a magnetic coupling ensuring a leak free process, and zero possibility of expensive, flammable or toxic liquids escaping. Liquids can be handled across a wide range of temperatures from -60°C to 220°C, which is not often possible with positive displacement pumps.

6. High Temperature Handling –Models can accept temperatures of up to 220°C, which when coupled with the low NPSH requirements means they are suited for boiler feed applications where high temperatures are coupled with low flows, and NPSH is very low. Magnetic Drive units eliminate the possibility of seal failure, or packed gland usage reducing maintenance intervals in this problematic type of application.

7. High Inlet Pressure –Units can accept inlet pressures of close to 100bar which can be experienced with condensates, CO2 and other gaseous liquids.

8. Low flows and High heads without pulsation –low flows of low viscosity fluids (<200cst) can be achieved which are typically performed by positive displacement pumps without pulsation.

Liquid Ring Pump Applications

Typical applications for such pumps are:

1. Condensate extraction

2. Hazardous liquid transfer of liquid gases such as Ammonia, LPG, Hydrogen or LPG

3. Boiler Feed

4. Hydrophore Systems / Pressure Booster Sets

5. Refrigerant Circulation & Transfer

6. Thermal oil transfer and Recirculation

7. Liquid CO2 recirculation

Side Channel Pump vs Multistage Pump | |

Liquid Ring Pump | |

Handle up to 50% Gas Content | Can not handle entrained Gas |

Self Priming by Design | Requires foot valve for manometric Suction lift |

NPSH Required as low as 0.2M meaning liquids close to boiling point can be extracted from containers | Typically requires 1M or more |

Available with Magnetic Drive for full containment of hazardous liquids | Sealing options typically limited to Mechanical seal, Double Mechanical Seal or packed gland |

Lower Flows and Heads | Higher Pressures and Flows possible |

Solid content must be <1mm | Can handle solids when designed to accommodate |

If this seems like the type of unit you require, our range can be viewed here.

Having issues with your pump? View our Side Channel Toubleshooting guide