What Are Submersible Pumps?

What Are Submersible Pumps?

Submersible pumps, also known as Electric Submersible Pumps (ESP) have hermetically sealed, electric motors to enable them to be completely immersed in the fluid being pumped. They are of centrifugal design and therefore are very efficient, requiring less energy for moving water into the pump than other designs of pump. Narrow submersible pumps are known as borehole pumps which are designed for extracting water from narrow holes drilled into the ground as narrow as 4”.

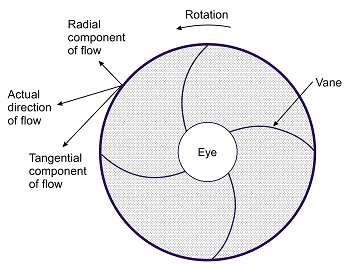

Fluid flows into the rotating impeller along its central axis and is propelled outward by centrifugal force, through the impeller’s vane tips. They are typically controlled by float switches which can trigger operation at various levels within a sump in which the pumps are located. A suction strainer on the bottom of the pump strains debris and solids.

Submersible pumps can be either free-standing where the pump casing has integrated feet or guide rail mounted. Guide rail-mounted means that the pumps are fixed with a bracket to a rail which runs the depth of the sump allowing for it to be raised and lowered via chains to the bottom of the sump, where it automatically couples to the discharge pipework. A freestanding pump is where the bottom of the pump has been designed with feet to elevate the suction port from the bottom of the sump to allow solids and liquids to enter the pump.

The range of submersible pumps available means that they can be used in a variety of applications, with some models enabling the transfer of solids without loss of pressure.

What are submersible pumps used for?

Due to the variety of submersible pumps available, they are often used in a number of applications such as;

Sewage transfer

Seawater handling

Irrigation

Pressure boosting

Pumping from wells or boreholes

Reducing nuisance groundwater, floodwater and dewatering

Types of submersible pump

There are various designs of submersible pumps.

Slurry versions have an agitator which works in conjunction with the impeller to stir up solids which may be compacted at the bottom of a lake to enable them to be pumped.

Puddle sucker pumps are suitable for taking water levels down to a few mm, with some capable of draining the water completely which is why they are called puddle suckers.

Portable submersible pumps are ideal for temporary applications, such as draining flooded areas. They are lightweight, easy to handle and reliable.

Manual vs Automatic Pumps

Depending on the location of your pump, application, power supply available and fluid being transferred will depend on whether you have a manual submersible pump or an automatic submersible pump.

As you would expect, a manual pump needs to be switched on or off manually and will require monitoring whilst in operation to ensure the pump does not run dry. Manual submerged pumps tend to be used in conditions where fluid levels are not consistent, such as removing unwanted nuisance bodies of water in an area.

Automatic submerged pumps with a float switch operate automatically when fluid levels reach a certain depth and will automatically cut out when the desired depth has been achieved.

Automatic pumps can operate via various float designs such as a float switch or tubular float switch attached to the pump. Puddle sucker designs operate via probes, which when in contact with a fluid cause the pump to begin operation.

The float switch contains a contactor which causes the pump to work as water levels rise causing the float switch to elevate and the contactor to complete the circuit starting pump operation. As water levels drop the contactor in the float switch separates from the circuit, causing the pump to be stop.

ATEX Submersible Pumps

ATEX rated submersible electric pumps transfer water and leachate in industrial applications. They are not recommended for use with flammable liquids such as fuels as they can potentially leak via seals into the motor over time and require regular thorough inspection.

If you are looking for an ATEX rated pump for flammable liquids it would be worth considering a self priming pump or vertical immersion unit.

Types of impeller that can be used on submerged pumps

Various impeller types can be fitted depending on the fluid being pump. A vortex impeller would be used to transfer solid laden fluids in which solids are suspended within the fluid such as sewage, or in wastewater applications.

Various impeller types can be fitted depending on the fluid being pump. A vortex impeller would be used to transfer solid laden fluids in which solids are suspended within the fluid such as sewage, or in wastewater applications.

A semi-open impeller allows for small occasional debris which may be present in dewatering or wastewater applications. A cutter or macerator impeller would be used for fluids containing stringy solids such as straw within manure or animal waste, industrial process waste or in domestic sewage transfer applications. When sewage needs transferring long distances, and through narrow pipework it oftens requires pumping high pressure to ensure the waste reaches the sewage drainage network.

This can often be the case when extensions are made to basements in built up inner cities such as London, or where properties are located in remote areas, where gravity is insufficient to allow sewage to drain away naturally through the existing network meaning a pump station is required.

Solid transfer submersible pumps

Solid transfer applications are typically required in industrial, mining and construction applications, as well as in sewage treatment, and dredging.

Submersible pumps designed for solid transfer are developed to handle fluids containing solids or slurries.

When considering a submersible pump for transferring solids within fluid, there are a number of considerations that need to be addressed such as;

Abrasive nature of the solids on the pump components and seals. For Example in some applications such as sewage transfer, the maximum speed should be limited to around 1500rpm to minimise wear, and maximise seal and bearing life.

Impeller design to avoid clogging

Sizing and capacity of the pump in relation to the size and concentration of solids in the liquid

Pump design to allow for maintenance within hazardous environments

Viscosity and Specific Gravity of the fluid as if this is too high it may flow insufficiently to allow cooling of the motor as in this case study

In addition what accessories may be required in addition to the pump, such as cutters for stringy solids, and agitators for slurry to enable improved operational efficiencies.

Pumping Wells and Boreholes/Bore wells

Submersible pumps are an ideal choice for transferring water from deep wells and boreholes into storage tanks. As the maximum distance a pump can prime from a body of water is 9.8M, often the most cost effective way of pumping is utilising a such designs, as they can be immersed at great depths and pump at large pressures. It is much easier for a pump to be immersed in a liquid and pump rather than a pump suck or create a vacuum and then pump.

Depth of submersion

By their nature, submersible pumps need to be fully submerged in the fluid they are transferring. This is because the liquid they are submerged in acts as a coolant and prevents the motor from overheating. When such designs are used in bodies of water where there is insufficient flow for effective cooling, a cooling sleeve is utilised.

Float switches or level probes should be incorporated into system design to ensure automatic cut out if fluid levels drop below safe operational levels.

Advantages of a submersible pump

They are compact compared to many other types of pump

As the motor and pump are directly coupled, they can be easier to use or manoeuvred than other types of pump

They can be installed in almost all locations which lowers operational costs and requirement for housing

Reduces the need for additional components such as suction pipes, shaft alignment, excess piping and valves

As they are submerged, submersible pumps take up no floorspace and are operationally quiet

Disadvantages of submersible pumps

As submersible pumps are submerged in fluid, it is often hard to carry out regular maintenance and see whether components like mechanical seals and bearings are degrading

Water ingress can cause motor failures

As submersible pumps are in sealed units, replacement motors are not typically available as separate components. In cases where they can be replaced, they may be on long lead times, and not available from multiple sources.

Cable glands can be weakened through certain actions such as manoeuvring the pump in and out of the chamber. This can cause water ingress into the motor.

The initial investment is higher when purchasing a standby pump as well as the duty pump.

The initial investment should also take into account maintenance entry, particularly if the pump is operating in a confined space.

How to maintain a submersible pump

As with any heavy duty asset, submersible pumps require the correct specification, installation and maintenance to ensure operational and life-span optimisation.

A schedule of weekly, monthly and annual maintenance checks and tasks should be undertaken, depending on the working conditions and the make and model of your pump.

Typically you may want to consider the following checks as a minimum;

During the weekly check:

Listen for unusual noises or vibrations while the pump is running.

Examine the flow and pressure at the discharge end.

Inspect pipework and valves for any signs of leaks.

Monthly:

As part of a monthly inspection:

Measure the power drawn from each phase to ensure it is balanced. If the reading has significantly changed since the pump's installation or if one phase exhibits notably higher or lower current than the others, stop the pump and seek advice from the distributor or manufacturer.

Employ an infrared thermometer for safe, non-contact heat detection to check for any heat emanating from wires or switches.

Verify that the float switch or any alternative level sensor, if installed, effectively shuts off the motor when the pump is lifted out of the water.

Confirm the oil level is at the correct level by tilting the pump slightly to allow a small amount of oil to drain from the downward-facing oil plug. If the oil appears discolored or mixed with water, consider replacing the seals before the next operation.

Ensure the strainer is free from obstructions or damage.

Six-Monthly/Annual Checklist:

In addition to the monthly routine checks, conduct the following tasks at least once a year:

Perform an oil change. Clean oil is vital for proper pump operation and lubrication. Always follow the instructions in the pump’s manual.

Examine the strainer compare the strainer's hole size to the pump's original specifications; excessive wear can allow larger solids into the pump than it can handle.

Inspect the impeller and volute to ensure that they are in good condition, following the manufacturer’s instructions.

Check the mechanical seal carefully and cable gland carefully for any signs of leakage

Examine the condition of both the inside and outside surfaces of the impeller and the volute. Worn surfaces and edges can diminish pump efficiency and performance, ultimately reducing its operational lifespan.

How North Ridge Pumps can help

If you need support identifying a submersible pump for your application, or have a pump in need of repair then we are happy to help.

Our team of experts are on hand to guide you though our range of submersible pumps so that you are able to correctly specify the pump you need to achieve efficient and reliable fluid transfer.

For more information contact us.