-

Applications

-

-

6 8Abstraction

-

6 9Atex

-

6 65Booster

-

6 213Centrifuge & Hydrocyclone Feed

-

6 10Chemical Injection

-

6 214Chemical Transfer

-

6 11Circulation

-

6 12Container Emptying

-

6 13Cooling

-

6 14Dewatering

-

6 15Dosing & Metering

-

6 16Drainage Station

-

6 17Edible Oil

-

6 18Effluent Transfer

-

6 225Filter Backwash

-

6 215Filter Press Feed

-

6 20Flocculation & Coagulation

-

6 19Fuel Transfer Pumps

-

6 21Grease Pump

-

6 23High Viscosity

-

6 24Hygienic

-

6 25Irrigation

-

6 216Liquid Organic Hydrogen Carrier

-

6 27Low Viscosity

-

6 28Lubrication

-

6 232Multiphase

-

6 217Pipe Flushing

-

6 30Pipeline Pump

-

6 32Sampling Pump

-

6 33Scrubbers

-

6 220Sewage Transfer

-

6 34Skimming

-

6 35Sludge Pumps

-

6 36Solid Handling

-

6 218Spraying

-

6 37Swimming Pool

-

6 38Tanker Unloading

-

6 219Test Rig Pumps

-

6 39Thermal Oil Transfer

Industrial Solutions

North Ridge Pumps Ltd are an independent manufacturer and distributor of pumps. Established since 1998, we have a wealth of experience in pumping applications, handling fluids from freshwater, seawater and glycols to heavy oil, grease, food and chemicals. Having worked in a variety of demanding industries both in the UK and Internationally, any fluid you can think of, we have most likely pumped it.

We can specify your ideal solution

Ask our industry leading experts to provide the perfect solution for your application.

LATEST NEWS

Sanitary Progressing Cavity Pumps For Lecithin and Cream Transfer

NEED HELP?

If you are unable to find the product that you are looking for then please contact us via [email protected] or call +44 (0) 1773 302 660

-

7 40Ballast

-

7 41Bilge

-

7 55Boiler Feed

-

7 231Cargo

-

7 42Circulation

-

7 43Cooling

-

7 227Drill Water

-

7 54Fire Fighting

-

7 56Fish Waste

-

7 60General Service

-

7 44Grey Water

-

7 230HT LT Cooling Pumps

-

7 226Hydrophore Systems

-

7 46Liquid Gas Pump

-

7 47Low Sulphur Fuel Oil

-

7 49Lubrication

-

7 229Main Engine Preheating

-

7 57Marine Fuel

-

7 222Methanol

-

7 228Reverse Osmosis

-

7 51Scrubbers

-

7 58Seawater Injection

-

7 52Sludge Pumps

-

7 53Solid Handling

Marine Solutions

North Ridge Pumps Ltd are an independent manufacturer and distributor of pumps. Established since 1998, we have a wealth of experience in pumping applications, handling fluids from freshwater, seawater and glycols to heavy oil, grease, food and chemicals. Having worked in a variety of demanding industries both in the UK and Internationally, any fluid you can think of, we have most likely pumped it.

We can specify your ideal solution

Ask our industry leading experts to provide the perfect solution for your application.

LATEST NEWS

Sanitary Progressing Cavity Pumps For Lecithin and Cream Transfer

NEED HELP?

If you are unable to find the product that you are looking for then please contact us via [email protected] or call +44 (0) 1773 302 660

-

-

-

Industry

-

-

191Agriculture

-

192Aviation

-

89Beverage

-

90Building Services

-

193Carbon Capture and Storage

-

91Chemical Manufacture

-

194Decommissioning

-

92Energy From Waste

-

93Energy Storage

-

195Foam Products

-

94Food

-

95Fuels, Biofuels and Petroleum

-

97Marine

-

98Mechanical

-

99Mining

-

100Oil & Gas

-

101Paint Print and Varnish

-

102Pharmaceutical

-

103Power Generation

-

104Pulp & Paper

-

196Railway

-

197Renewable Energy

-

198Rubber and Plastics

-

105Surface Treatment

-

106Wastewater Treatment

-

-

-

Liquids

-

-

121Beverages and Drinks

-

202Bitumen

-

203Chemicals

-

123Chocolate and Sweets

-

124Coagulants & Flocculants

-

125Corrosive Liquids

-

126Cosmetics

-

127Dairy, Milk & Ice Cream

-

204Drilling Mud

-

128Edible Oils & Fats Transfer Pumps

-

129Fish & Seafood

-

130Food Transfer Pumps

-

131Fresh Water

-

132Fuel Pumps

-

133Glues

-

206Glycol

-

134Grease

-

135Ink, Paint, Print & Varnish

-

208Latex

-

138Meat & Poultry

-

139Oils

-

223Polyethylene & Polyurethane

-

209Polymers

-

31Pulp

-

210Resin

-

143Seawater

-

144Sewage

-

145Sludge

-

146Slurries

-

147Solids and Abrasives

-

148Surface Treatment

-

211Thermal Oils

-

149Viscous and Sensitive

-

150Wastewater

-

212Wax

-

-

-

Pump Types

-

- Pump Kits

-

221Accessories

-

63AODD

-

64Barrel

-

66Booster Sets

-

67Borehole

-

82Centrifugal Pumps

-

200Circulator

-

76Dosing and Metering

-

68Flexible Impeller

-

69Gear

-

70Hand Operated

-

71Lobe

-

72Magnetic Drive

-

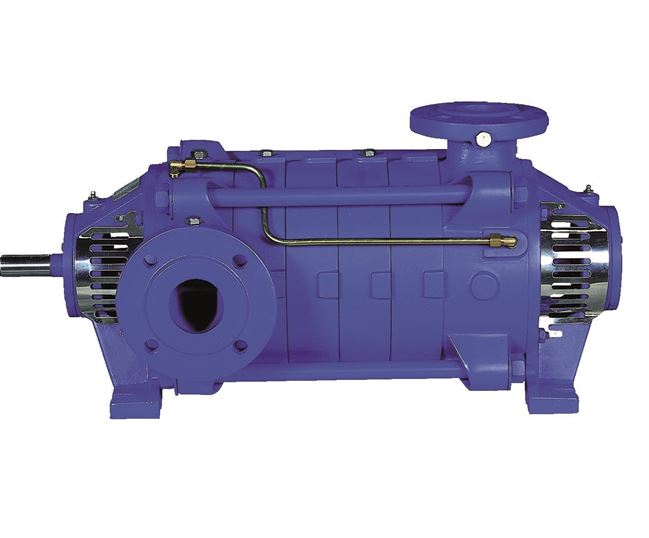

73Multistage

-

74Peripheral

-

199Peristaltic

-

75Piston/Plunger

-

77Progressing Cavity

-

224Pump as Turbine

-

78Rotary Piston

-

79Screw Pumps

-

80Self Priming Centrifugal

-

81Side Channel

-

83Split Casing

-

84Submersible

-

85Vane

-

86Vertical Immersion

-

87Vertical Inline Centrifugal

-

-

Spare Parts

-

Brands

-

Resources

- Case Studies

- Pump Repair