Flexible Impeller Pump Guide

How does a flexible impeller pump work?

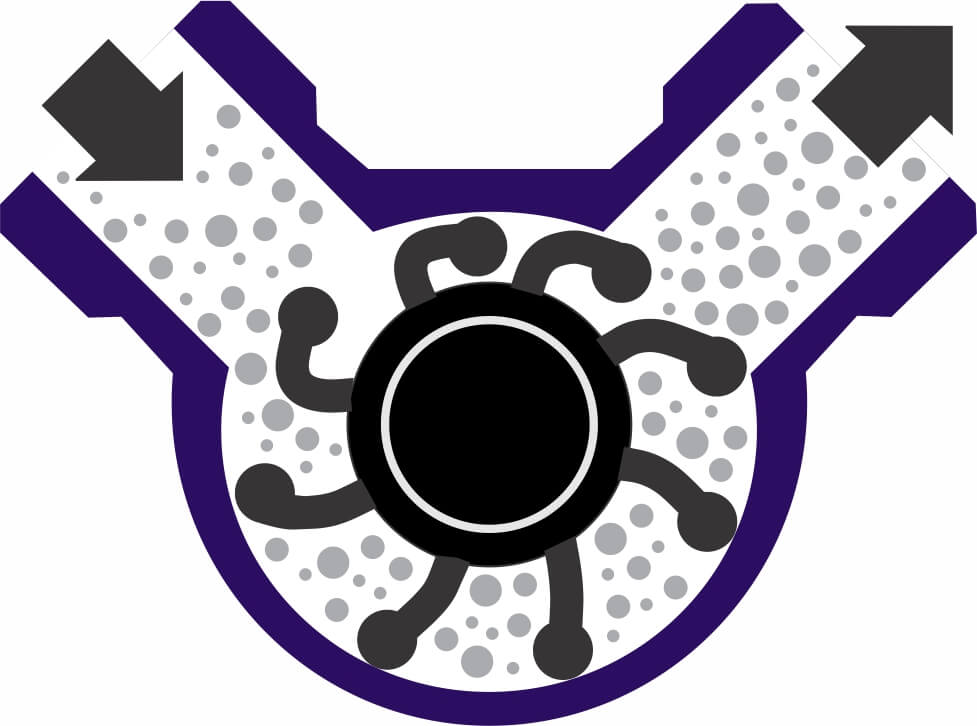

A flexible impeller pump is a type of pump design which consists of a circular rubber impeller with several flexible rubber vanes mounted within a casing.

The casing is smaller than the impeller vanes, meaning to insert the vane into the pump head, the vanes must be bent creating a seal and chamber between each vane. The pump head then contains several chambers which operate like valves, making the pump self-priming, and a positive displacement pump.

There are numerous advantages of a flexible impeller pump, which are:

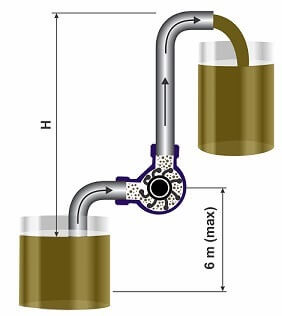

· Self-prime from dry and prime up to 6M.

· High flow capacity and can operate at full motor speed with low viscosity fluids

· Versatile - can be run at different speeds to accommodate differing viscosities. As the pump is positive displacement its pressure will also be constant, and the flow rate proportional to speed.

· Works in any location. The nature of the pump means it is a preferred pump to be used by machine builders as it can be mounted in almost any position and still work as intended.

· Gentle pumping action ensures the consistency of the fluid remains unaffected by shear forces e.g. milk, cream, thixotropic fluids.

· Flow is also non pulsating, meaning the output can be measured very accurately with a flowmeter.

· Easy Maintenance due to few moving parts – only 8 parts in total. 4 of which are wearing.

· Solid Handling capability – solids can be handled with ease, but also without damage. Seeds, grapes and fruit in suspension can be handled gently, retaining solid integrity. It is favoured in the brewing industry as not only does it pump gently, but it can handle solids. Solids are also kept in suspension which can be important with textured products, such as; yogurts, drinks, or sauces.

· Cleaning in Place friendly – Such pumps are very easy to dismantle and clean

· Reversible to enable multiple applications to be used by one pump, such as; tank loading and unloading

· Many accessories available to optimise the pump to your process, including; carry handle, variable speed drive, trolley, flowmeter, and hosing.

· Pump head can be made with differing connections, such as; BSP M, BSP F, RJT, Tricover, Triclamp to suit your process.

Flexible impeller pump vs centrifugal?

Flexible impeller pumps are often compared to centrifugal pumps, however the two are quite different. A flexible impeller pump is a different pumping technology, positive displacement. This means the pump prevents liquid recirculating in the pump head and back towards the inlet. Its pumping motion is always forward, or positive, as opposed to centrifugal pumps where fluid can recirculate back towards the inlet.

Flexible Impeller Pumps Vs Centrifugal | ||

FLEXIBLE IMPELLER | CENTRIFUGAL | |

Flow rate | Low to Medium. Flow rate directly proportional to speed | Low to high |

Flow Type | Non Pulsating | Non Pulsating |

Pressure | Low to medium - Up to 40M Not affected by inlet pressure | Low to High - Up to 200M |

Priming | Self-Priming up to 6M | Only self-priming by special design or with a foot valve |

Abrasive Liquids | Yes | No |

Solid Handling | Handles Solids as standard and kept in suspension | Not as standard. |

Shear | Low shear – pumped product remains unchanged and is handled gently | High Shear. Single cream in – double cream out. |

Viscosity | Up to 50,000 cst | Up to 300cst |

Reversible | YES | NO |

Cleanability | Very easy to dismantle and clean. Can be cleaned by CIP. Impeller can need removal to clean properly. | Can clean through CIP. Does not usually require disassembly |

Speed | Due to the impeller touching the casing, speed is limited to a maximum of 1400rpm | Can operate at full motor speed up to 2900rpm / 3600rpm |

Entrained Gas Handling | Can handle entrained gas | Can experience vapor locking with gas entrained fluids |

Suitable for Metering | Yes. Flow and pressure consistent | No. Flow and pressure can vary. |

Noise | Can be noisy | Quiet when operating efficiently |

Temperature | Up to 100°C | Up to 300°C |

Size | Compact if not utilizing a gear box | Compact or base plate mounted. |

Atex Rated | No | Some models Yes |

Starting Torque | High | Low |

How to Prime a flexible impeller pump?

A flexible impeller pump is self-priming from dry up to 3M. Flexible impeller pumps should not be run dry, but in order to help with priming on start-up during first use, ideally both inlet and outlet ports should be filled with fluid to lubricate the impeller and assist with priming. If possible, the front cover should also be removed from the pump and the chambers filled with the fluid to be pumped, which will help fully lubricate the impeller upon first use.

Flexible Impeller Pump Wear

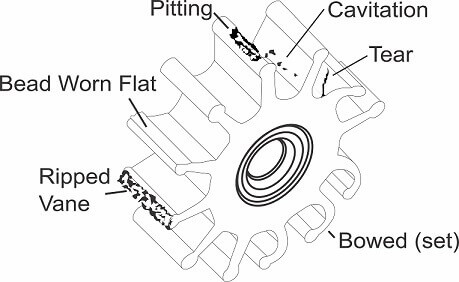

Normally the flexible rubber impellers should be replaced annually, or if any of the below conditions are present:

1. Flexible impeller blade bead is flat

The tip of the impeller should be bent and form a tight seal against the pump casing. If any part of the impeller begins to wear, this will cause inefficiency within the pump causing the pump to lose suction, flow rate and pressure.

2. Impeller blade pitting (cavitation)

Any pitting on the impeller vanes reduces the structural integrity, limiting the pressure generating ability of the pump. Parts of the vane can break off contaminating the fluid. Possible causes of pitting can be chemical attack. A recent change in the additives used in oils has meant flexible impeller material may now be unsuitable and require changing.

3. Impeller vanes torn

Any tears in the rubber vane will affect the strength of the vanes, limiting the priming ability of the pump, and the pressure generating ability of the pump. If a blade snaps off, it can contaminate the product or jam the impeller, causing the motor to burn out. Impellers which are torn can be a sign of another problem stemming from over pressure, or chemical compatibility.

4. Flexible impeller blade set in bowed position (set)

Over time or due to hardening, a flexible impeller pumps blades can become permanently deformed. This then limits the priming ability of the pumps and causes slippage within the pump head causing flow rate to drop. Pressure generated by the pump will also be limited. Impellers set in a bowed position can be caused by long term use, or due to oils within the rubber being stripped, causing the rubber to harden. This can happen if the impeller is in contact with fluids which are incompatible with the rubber.

FAQS

The rubber impeller may also melt or deform even after short periods of dry running. Our advice is to ensure that the pump always has access to fluid while running, the vessel or sump on the inlet side of the pump must never run out of fluid while the pump is active.

Level sensors or a float switch can be installed in the fluid chamber ensuring that the pump is turned off in the event there is no fluid. Another way of protecting the pump is to fit a dry run protection, this will turn the pump off if it detects that no fluid is entering the pump.

If you think that dry running is inevitable, then please speak to us and we will try to select a more suitable pump for your application.

For fluids with a viscosity of approximately 100 cP a 25% loss can be expected, for products with a viscosity of approximately 4000cP, a 60% loss can be expected.

This all needs to be considered when selecting a suitable model.