Pulsation Dampeners

Positive displacement pumps such as air operated diaphragm pumps and peristaltic pumps can create a pulsating flow which is a pressure spike or batch of high pressurized flow, due to their design.

Pulsating flow can cause a number of undesired outcomes such as product foaming, inconsistent flow, overpressure, water hammer, pipework vibration and inconsistent readings from metering equipment which require reducing or eliminating.

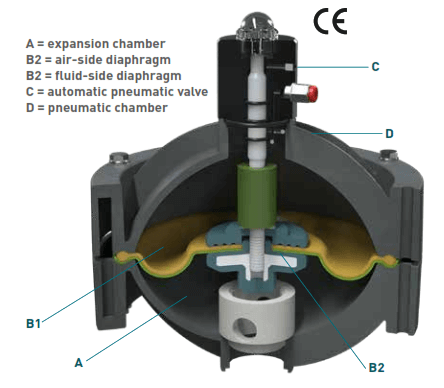

Pulsation dampeners are designed to absorb the excess pressure by up to 80% to prevent and limit these undesired outcomes acting similar to a car's suspension. They are designed to either be pressurized by a compressed airline or via the same air connection to an Air Operated Diaphragm Pump to use pressure to counteract and limit the effect of overpressure. Pulsation dampeners require little maintenance and are often fit and forget. They should be fitted as close to the outlet of the pump as possible.

If you are experiencing issues with product foaming, inconsistent flow, water hammer, pipework vibrations and irregular readings from flowmeters discuss with us today to understand if a pulsation dampener will solve these issues.