What are Peristaltic Hose Pumps?

What Are Peristaltic Hose Pumps?: Learn How A Peristaltic Pump Works & How They’re Used

Hose pumps are versatile devices used in various industries for pumping fluids. They operate by compressing a flexible tube, creating a positive displacement action. These pumps are commonly used in chemical processing, wastewater treatment, mining, and food production due to their ability to handle abrasive or viscous materials efficiently.

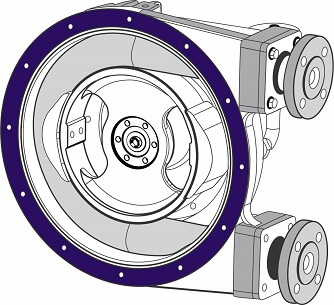

A peristaltic pump (also known as Hose or Squeeze Pump) is a rotary positive displacement pump which is a simple design consisting of a single piece of hose which is compressed via rollers or shoes moving fluid from the inlet to the outlet of the pump.

How a peristaltic pump works

Each unit comprises of a motor, gearbox, hose and either shoes or rollers. They operate via rollers or shoes compressing a single part known as the hose or tube to create a vacuum and create flow and pressure.

As the unit does not contain valves it is known as a non-clog pump. Peristaltic pumps are self-priming, which can create suction lifts up to 8M from dry, handling air without issue. The rotary motion of a peristaltic is very slow, which is why a gearbox is used to step down the motor speed to as little 1rpm within the pump head. View our Peristaltic Pump animation

Roller vs shoe pump

Peristaltic pumps designs vary, with the method used to compress the hose varying between models.  Our low pressure design of pumps utilise roller designs and higher pressure utilise a shoe design.

Our low pressure design of pumps utilise roller designs and higher pressure utilise a shoe design.

View our comparison table below to understand the differences between a roller and shoe peristaltic pump:

Roller Peristaltic Pump | Shoe type Peristaltic Pump |

Utilises 30% less Energy | Uses more energy |

Longer hose life as virtually no friction between rollers and hose leads to lower power consumption and motor required | More abrasive to hose meaning hose must be immersed in lubricant |

Wide Frequency Range starting from 1Hz meaning very low flows can be achieved | Longer hose life on 5-15 bar applications due to higher mechanical efficiency |

Easy Hose Replacement as lubricant does not need to be emptied from the pump to change the hose | |

Only Small amounts of lubricant required | |

Smaller Rotor meaning lower power consumption | |

Where are peristaltic pumps used?

Peristaltic Pumps are used in most industries as due to their design they can handle anything from clean low viscosity fluids to sludges and slurries with abrasive particles such as rocks, cuttings or metal particles. They can handle a viscosity from 1cst to 55,000cst making them suited for most fluids.

Applications tend to be where there is a requirement for a low to medium flow (36,000 L/hour) at low to high pressure (15 bar).

Low Viscosity

At low flow and pressure they can be used for ground water sampling, gearbox filling, chemical transfer, and for mouse perfusion which is the preservation of organ / tissues by the passage of a chemical such as formaldehyde though a mouse’s circulatory system.

Pharmaceutical / Hygienic

As hose pumps are low shear they are often used in laboratories as they can transfer fluids without changing their consistency, nor damage cell culture and are also used within the food industry for machine filling. They can operate as low as 1Hz accounting for the most minute quantities at low pressure.

As the designs consists of only one fluid contact part they are often used in high sterile applications where a single use pump are required. Hosing on smaller pumps can be replaced in minutes between applications ensuring sterile single use pumps for bioprocessing and life sciences. Hosing can be supplied in long lengths, which is cut for use per application, and disposed of once used preventing cross contamination.

Gassing Fluids

They are especially suited for fluids which may gas such as Sodium Hypochlorite as they do not contain valves or seals which can be opened when exposed to an increase in pressure, which often happens with diaphragm pumps allowing leakage. If centrifugal pumps are used with fluids which gas, it can cause vapour locking.

High Viscosity Fluids

They are also known as high viscosity fluid pumps accustomed to handling liquids such as slurry, grout, concrete, cement, and Glycerine up to a viscosity of 55,000cst. As the pump is reversible it also means such problematic fluids can be easily recovered from hoses and equipment which can solidify when exposed to air or when cooled. Hoses are robust and multilayered meaning they handle abrasive slurries, debris and objects very well.

They can also be used for chemical injection due to their accuracy and delivery of low flows at high pressure, without requiring suction and delivery valves.

Peristaltic pumps are not really used for solvents. Solvents generally require to be handled using PTFE which is very rigid and not very flexible. Even when used in an Air Operated Diaphragm pump the back of the diaphragm (air side diaphragm) must be another material to ensure it is more flexible and can withstand the constant flexing shear motion. Such pumps are also not used for high flows (>36M³H) of clean low viscosity fluids which are better suited for a centrifugal pump.

How to calculate peristaltic pump flow rate & how accurate are Peristaltic Pumps?

Peristaltic Pumps are 99% accurate in dosing applications which are continuously working, or batching. However in batching applications as pumps contain twin shoes or rollers which do not always start and stop in the same position, meaning at times a shoe or roller can compress the tube an additional time in one batching cycle than others.

This will cause a different volume to be dispensed at times, and so for the batching accuracy of any peristaltic pump it is flowrate dependent by pump model. Every pump has a capacity which is detailed as the number of ml per revolution, and is generally a ¼ of the capacity of the pump.

For example in our FMP30 the capacity is 433ml per revolution, so the minimum accuracy will be +- 108ml as to the significance of the figure depends on the total flow expected. Accuracy can be improved through the use of a flowmeter and control valve, as the flow is directly proportional to speed and so a very predictable flow rate can be achieved.

Why are peristaltic pumps used?

Peristaltic pumps are used due to the following advantages:

Self Priming: Due to their design they are self priming up to 8M.

Low & Easy Maintenance: As there is only one wearing part, the hose they are known to be very low maintenance. When the hose requires replacement, it can be exchanged very simply.

Reversible: Their rotation can be reversed meaning they can be utilized in a number of scenarios such as container filling and emptying but also ensure any associated equipment such as hoses can be drained if required.

Non Clog: Such designs can accommodate solids as large as the internal diameter of the hose, and due to the movement do not clog. This makes them ideal for sewage, sludge and other applications which can contain large dry solids, rags, or unexpected objects.

Low Shear: Due to the nature of movement, and when fitted with rollers operating as low as 1Hz, they can handle the most sensitive of liquids without changing consistency or damage to cell culture.

Abrasion Resistant: Due to the tough, hard wearing hose, slow speed and gentle action pumps can handle the most abrasive of slurries from mining or other applications which may contain sharp particles or debris.

Valve less: With the absence of valves there is no potential for clogging or build up of limescale.

Seal-less: Due to the absence of a mechanical seal, gaskets and O-Rings they are very low maintenance. There is no opportunity for problematic fluids such as glues, or latex to cause seal failure allowing ingress of air reducing efficiency, and consequential loss of product.

Variable speed: Due to the nature of design the pumps are known as a volumetric pump meaning that flow rate is proportional to speed, but pressure remains constant. Units can be fitted with a wide variety of motors from dc motor, single / three phase motor to hydraulic motors.

High temperature: Peristaltic Pumps can handle temperatures up to 110°C with little effect, where as other positive displacement pump types such as progressing cavity must be operated within narrow bands of temperatures and air operated diaphragm pumps have a limit of 80°C.

Peristaltic pump accessories

Accessories available for use with peristaltic Pumps include:

Vacuum assist: This device is an air driven vacuum pump which creates a vacuum within the pump casing, enabling the hose to return back to its original shape quicker which helps with priming of viscous liquids but also to maintain flow and pressure.

Leakage Sensor: A leakage sensor detects when the hose has burst and product is leaking. This enables fluids to be pumped safely knowing should a leakage occur an alarm will sound, or pump stopped. Due to the design, it also enables full containment.

Pulsation Dampeners: Pulsation dampeners limit the pulsations created by pumps, leading to a 98% reduction in fluid surges.

Hoppers: Hoppers enable pumps to fed with highly viscous liquids where without they may struggle to prime without as they contain an auger screw, which can operate without fluid, either on demand in conjunction with a product sensor or continuously.

Hoppers: Hoppers enable pumps to fed with highly viscous liquids where without they may struggle to prime without as they contain an auger screw, which can operate without fluid, either on demand in conjunction with a product sensor or continuously.

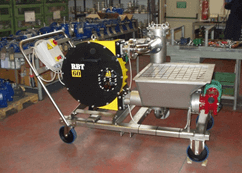

Trolleys: Trolleys enable the pumps to be moved between processes easily, enabling easy portability.

Chemical Coating: At times leakage can occur during hose replacement or hose rupture. A chemical coating in Halar enables the pump to withstand any residue or dust particles present in atmosphere.

Integrated Inverter: Pump mounted inverter enabling local speed control as well as reversibility.

Peristaltic vs Diaphragm Vs Gear vs Centrifugal Pump

Peristaltic | Peristaltic Vs Progressive Cavity | Peristaltic Vs Gear | Peristaltic Vs Centrifugal |

Higher suction Capability | Peristaltic Pump can dry run | Higher suction Capability | Designed for high viscosity fluids >300cst |

No issues with liquids which gas such as Sodium Hypochlorite | High Abrasion resistance | High solid content handling | No mechanical seal or O Rings. |

No requirement for suction and discharge valve | Very gentle pumping motion for shear sensitive fluids such as polymers | Higher pulsations | Very gentle pumping motion for shear sensitive fluids such as polymers |

Additional accessories such as foot valve or injection valve are not required | Dosing is proportional without slip. | Consistent pressure without loss of flow | |

Better dosing in variable pressure applications | No mechanical seal or O Rings. | ||

High solid content handling | |||

Reversible |

Having issues with your peristaltic pump? View our troubleshooting guide.

Also read our guide on 7 features to look for when specifying a peristaltic pump or View our Peristaltic Pump Brochure