Sanitary Centrifugal Pump for Hot Water and Oil in the Faroe Islands

Customer's Fish Oil Process

A Fish Processor in the Faroe Islands needed to empty tanks containing hot water and oil at 100°C which was present after cooking and could be utilised within another process.

The customer required a sanitary solution which would enable the fish oil to be recovered and utilised without contamination, handle near boiling water and oil, and was suitable for Cleaning in Place (CIP). The customer required only a small unit which could transfer 80-100L at a time, at a head of up to 2M.

Recovery and recycling of fluids in all areas of food manufacture is becoming of increasing importance, in particular with Fish Oil where it is utilised within nutritional supplements retailing at prices around £1500- £2500 per Ton.

North Ridge's Compact AISI316 Hygienic Pump Solution

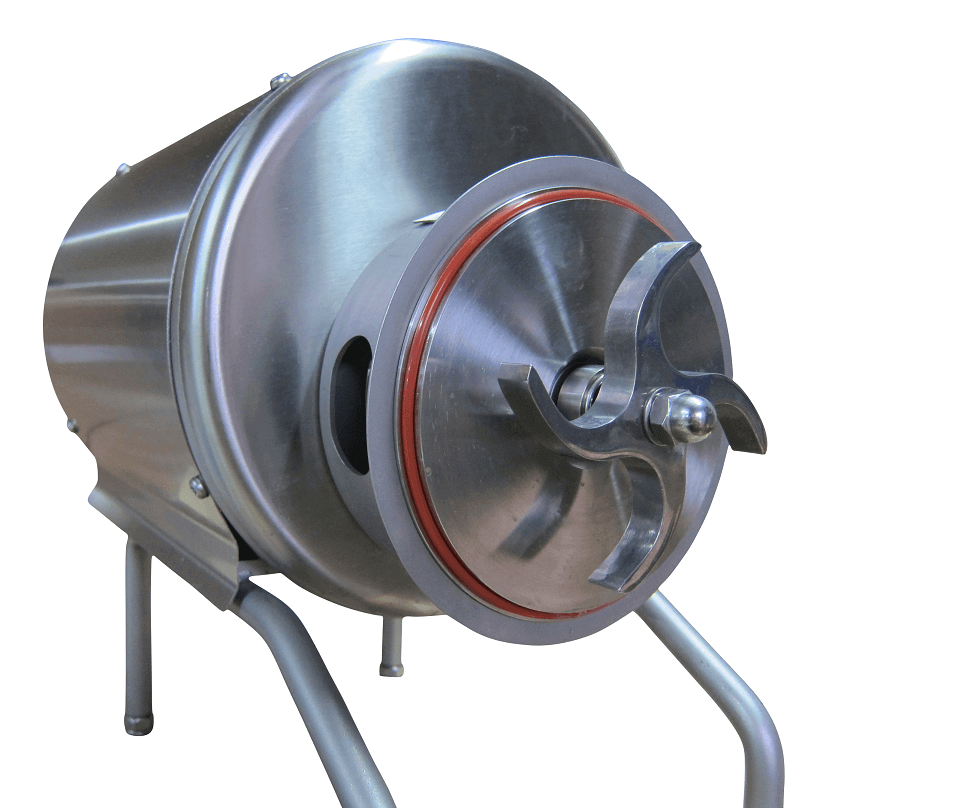

North Ridge quoted our FL51CI Small Hygienic Centrifugal Pump which is constructed in AISI316 and fitted with an open impeller, sanitary Silicone seal, and with a motor covered shroud. The unit will transfer at a flow rate of 40-50L/min meaning the tank would be empty within 2 minutes.

One of the unique features of the FL51 pumps is the one clip casing design. The pump casing is held via a unique robust casing clip which is tightened by a heavy duty hexagonal bolt. This enables the pump head to be quickly opened, and manually cleaned if required reducing dismantling and cleaning times by up to 50%.

Furthermore the pump is suitable for both Cleaning in Place (CIP) and Sterilisation In Place (SIP) with temperatures up to 140°C due to the Mechanical Seals thermosiphon cooling system manufactured in Silicon Carbide/ Viton / Silicon Carbide.

IP55 Shroud Protected Motor

The motor casing is protected by a shroud enabling the motor to be washed down easily without risking water ingress into the IP55 motor or bearings, as well as enabling process hygiene to be maintained. Although IP55 motors are usually protected against dust and jets from any angle, prolonged contact with water can mean it enters motors, so it is important that the unit be protected.

The unit is also mounted on legs or on a tripod helping to protect the unit from fluids which may be present at floor level further reducing the possibility of contamination. Pump connections were made in RJT a type of hygienic fitting.

The unit is also mounted on legs or on a tripod helping to protect the unit from fluids which may be present at floor level further reducing the possibility of contamination. Pump connections were made in RJT a type of hygienic fitting.

With a unit designed in full Stainless Steel, and with polished internal surfaces to Ra < 0.5 µm Surface Finish, the FL51 provides the perfect solution for hygienic fluid transfer.