High Pressure Diesel Screw Pump for Industrial Test Rig

A specialist in fuel filtration and the manufacture of fuel filters was about to commence the manufacture of a bespoke filter for a large truck OEM when their R&D Laboratory Manager approached us with a requirement that they were having great difficulty with.

A specialist in fuel filtration and the manufacture of fuel filters was about to commence the manufacture of a bespoke filter for a large truck OEM when their R&D Laboratory Manager approached us with a requirement that they were having great difficulty with.

The filter has an internal relief valve that will crack at a set pressure, their task in the laboratory was to build a small test circuit for subjecting the relief valves to an open/close cycle simulating real working conditions of hot fuel at 90°C.

Test Rig Working Conditions

The test rig has a working fluid of either diesel or ISO5 oil, due to the high running temperature of 90°C, the viscosity is very low at 2.5 mm2/s (cst). They required a fuel pump that could produce a pressure of 20 bar at a flow rate of only 5 to 10 litres per minute.

They previously ran simulations for pressure testing parts using a high-pressure gear pump, however it failed quickly under these conditions. Traditional gear pumps struggle with thin fluids and they found that the fluid shear using ISO5 was too great and that this was exacerbated with the high temperature. The gear pump that they tried soon suffered catastrophic failure.

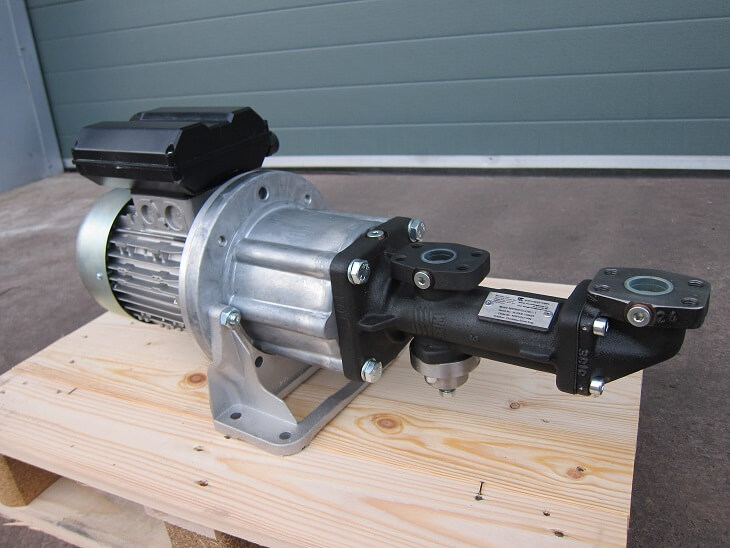

The customer then realised that they needed a pump solution that could handle a combination of thin fluid, high temperature and still cope with the 20 Bar pressure, this led them to contact us. After understanding the parameters and the issues the customer had been experiencing, we specified our NRPB40/GGG40-1.1 horizontal triple screw pump. This unit is perfectly suited to their process and has many benefits over the gear pump they used for testing.

Why use Screw Pumps for thin fluids at High Pressures

Screw pumps are excellent at handling clean lubricating liquids like fuels and oils, however unlike gear pumps, they cope with low viscosity fluids down to 1.2 cst without damage. In addition to this, they are highly efficient, compact due to the absence of a gear box, produce less pulsations and are quieter while running.

The 20 bar pressure is not an issue for this range as we have models that can create pressures up to 40 bar, ideal for a wide variety of test stations and other high-pressure applications. Furthermore, we can install sealing systems that enable the transfer of high temperature liquids up to 150°C, making this application at 90°C a breeze.

To protect the client’s system and components, we installed the oil pump with an integral pressure relief valve. The valve is set to 10% above the operating pressure, the valve then opens once the set pressure is reached causing the fluid to recirculate within the pump head instead of building up in the pipework and damaging components such as flow meters and valves. We always advise installing an external relief valve in addition to this, however the integral valve is the first line of defence.

Specification

Below is the specification of the pressure test fuel pump that was supplied:

Model: | NRPB40/GGG40-1.1 Horizontal Triple Screw Pump, with Built-In Pressure Relief Valve |

Flow Rate: | 9.88 L/min |

Pressure: | 20 Bar |

Materials: | Cast Iron casing and nitride steel screw set |

Inlet/Outlet: | 2”/1 ½” |

Motor: | 1.1 kW/230V/1Ph/50Hz/2900 RPM/IP55 |