Motor Mounting Codes & Positions

What do motor frame numbers mean?

Motor frame numbers are a set of common dimensions such as shaft size, shaft diameter and bolt hole mounting dimensions making motors interchangeable on a piece of equipment.

Whilst the power (Kw) and overall dimensions of a motor may change such as length, or diameter, the above will remain the same making them exchangeable.

There are two International Standards Organisations -the IEC (International Electrotechnical Commission) and NEMA the (National Electrical Manufacturers Association) which mainly caters for the North America Market which detail motor frame sizes.

On some pump designs, in particularly on close coupled versions it is common for pump manufacturers to machine the shaft to fit the pump head, meaning if a replacement is sourced its shaft will require machining before it can be connected to the pump head. It can also be extended in some designs. In such cases the motor nameplate is marked with a Z to indicate this.

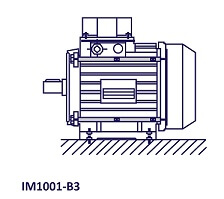

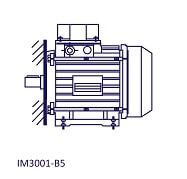

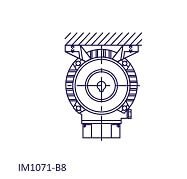

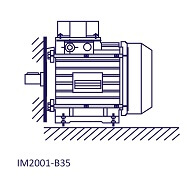

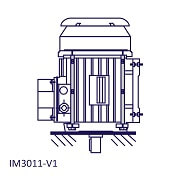

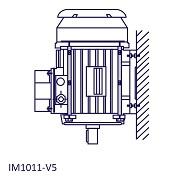

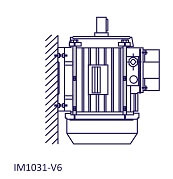

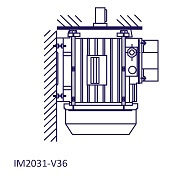

Electrical Motor Mounting Positions Chart

B3 Horizontal Foot Mounted

| B5 Horizontal Flange Mounted

| B6 Wall Mounted with Feet Left Hand Side When Viewed from

|

B7 Wall Mounted with Feet Right Hand Side when Viewed from Drive End

| B8 Foot Mounted on Ceiling

| B35 Foot & Flange Mounted

|

V1 Vertical Flange Mounted with Drive Shaft | V3 Vertical Flange Mounted with Drive Shaft

| V5 Vertical & Wall Mounted Drive Shaft Facing Down

|

V6 Vertical & Wall Mounted Drive

| V15 Vertical with Shaft Facing Down

| V36 Vertical with Drive Shaft Facing Up Flange & Foot Mounted

|

IP Ratings

Casing Protection Against Ingress of Solid Particles | Internal Protection against ingress of liquids | ||

0 | No protection | 0 | No Protection |

1 | Above >50mm such as large parts of the body or objects | 1 | Protected against vertical drops of water such as rain, drips and condensation |

2 | >12.5mm such as fingers or other objects | 2 | When tilted at 15°, water dripping vertically will have no harmful effect |

3 | >2.5mm wires, screws, nails or tools | 3 | Water spray up to 60° |

4 | >1mm Wires, or small nails or screws | 4 | Water Splashing from any direction |

5 | Dust protected with limited ingress | 5 | Projected water nozzle 6.3mm from any direction |

6 | Dust Tight – complete protection against particles | 6 | Powerful 12.5mm Water Jet from any direction |

7 | Immersion up to 1M | ||

8 | Immersion Beyond 1M | ||

Download and keep our Electrical Motor Mounting Position Chart