Paper & Pulp Industry

Despite technological advances, paper manufacturing is steadily increasing, with it reaching 400million tonnes per year globally in 2018. Paper is seen as a far environmentally friendly material for use and recycling than plastics despite it using an average of 54M³ to produce 1 tonne of paper. Paper use is increasingly used to replace plastic where possible in packaging and in single-use plastics which will be prohibited in Europe shortly.

Due to the nature of processes containing pulp, sludges, chemicals and high volumes of wastewater the pumps used in production include end suction centrifugal, peristaltic, progressing cavity, Air Operated Diaphragm and Gear pumps.

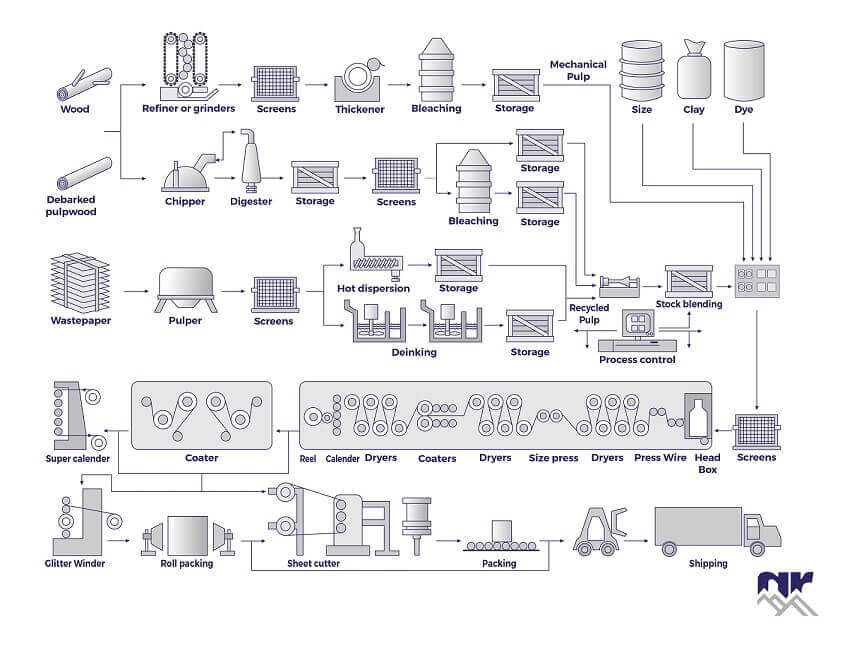

There are several stages of processing during paper and pulp manufacture in which the first is debarking when the wood is used as the source of cellulose.

Debarking

High-pressure water pumps are used to remove the bark. End suction centrifugal pumps or immersed pumps recirculate water at high pressure until all bark is removed. Solid handling and high pressure are an important aspect of this process

Cellulose Pulp Transfer from Wood, Waste Paper and Rags

After debarking the Pumps transfer cellulose pulp derived from wood chips. Cellulose pulp is obtained via chemical or mechanical means to extract cellulose fibres. If pulp is derived from recycled paper a pump which can defiber, deknot, blend and repulp paper utilizing a bridge breaker design. Paper from rags can have long or short fibres which require additional mechanical agitation requiring a double bridge breaker. Pumps which can accommodate a high solids content are favourable for such process. Such cellulose is transferred to the dosing system which mixes with fillers, fixatives and dye in order to produce the required paper.

Tank Dye, fillers & Fixatives

For the paper to receive a particular appearance, feel and thickness a combination of dyes, fillers, fixatives and bleaching can be used to obtain the desired finish. Pulse free pumping is required ensuring uniform consistent finish in which a positive displacement pump is ideal which can accommodate variations in viscosity, where the flow can increase linearly through speed control and pulse-free pumping via a progressing cavity pump.

Washing

High flow pumps for washing of paper which reduces the chemical requirement for bleaching. Efficient pumps running at a low rpm continuously provide the lowest running costs. Any chemicals added are recovered where possible to reduce operating costs.

Chemical Recovery

Recovery of liquors is typically performed via corrosion-free pumps. Black liquors are extracted during the washing cycle which is concentrated via evaporator service and can be used as a fuel to reduce mills operating costs.

Black and green liquors can also be converted back to white liquor through recausticising for reuse. Pumps in duplex materials which can accommodate the chemicals introduced during slaking such as lime, and calcium oxide which can crack traditional stainless steel materials.

We incorporate the following Pump Features to assist your pulp process: -Pulse free pumping ensuring consistency of product, dye and transfer rate

-Pulse free pumping ensuring consistency of product, dye and transfer rate

-Variable Speed Driven to accommodate increased demand but also to save energy during low production

- Non-clogging design reduces maintenance costs and disassembly

- Overhung design for process duty

View our range of Pumps for the Paper Industry