Abrasive grout transfer Pumps for Power Station

Abrasive grout transfer Pumps for Power Station

A construction company contacted North Ridge Pumps recently regarding two grout transfer pumps to be used for a new power plant being built.

Of course, you’ll probably know what grout is and what it’s used for. So why is industrial grout any different?

What is industrial grout and where is it used?

Like domestic grout used in domestic DIY, industrial grout is a composite material usually made of sand, cement and water. It can also include amounts of epoxy resins or other materials to give it greater durability and chemical resistance.

It is used basically to fill gaps, but in industrial settings it is applied in a variety of applications in construction, industrial processing plants, factories and other environments to:

Fill gaps and voids under base plates, heavy machinery and other structures to ensure a secure, stable and safe installation with no vibration

Seal joints and openings in a range of surfaces, stopping moisture and debris from getting in and causing damage

Reinforce existing structures by filling in voids and cracks to help improve their strength and durability

Fill joints between stones and tiles in industrial floors and walls

Give additional stability and protection to machinery working in harsh or extreme conditions

But it does have its drawbacks

Industrial grout is an extremely useful material, but it does have disadvantages and pumping it brings its own unique challenges.

Grout is abrasive in nature, packed with solids and liable to separate into its constituent parts. It also needs to be pumped at high pressure when it is being transferred long distances.

If the pump seals fail, it can quickly cause leakage in some types of pump design. Additionally, the pump can wear out much more quickly if incorrect type of pump has been specified.

So what is the best kind of pump for grout transfer?

Peristaltic pumps are the ideal choice for grout transfer

Peristaltic pumps are well suited for a variety of construction applications which need abrasive grout to be transferred and injected.

They are particularly suitable for projects where the grout transfer pumps may be inoperative for long periods, or when downtime during batches would not be an option.

A peristaltic pump, also called a squeeze pump or hose pump, is a type of rotary positive displacement pump.

How do they work?

Each unit is a very simple design made up of a motor, hose, gearbox and either shoes or rollers. The single piece of flexible hose is compressed by the rollers or shoes to create a vacuum and produce flow and pressure. This moves the fluid inside from the inlet to the outlet of the pump.

As each unit doesn’t have any valves, there is less to go wrong which is why it is also known as a non-clog pump. In addition, peristaltic pumps are a self-priming design able to produce creating suction lifts up to 8m from dry, and handling air without any problem.

The rotary movement of the peristaltic pump design is very slow. So a gearbox is added to bring the motor speed down to as little 1rpm inside the pump head.

Which is best for industrial grout transfer - shoe pump or roller pump?

Neither design is inherently better or worse. The designs of peristaltic pumps vary depending on what the pumps will be used for. This will dictate whether a shoe or a roller is used to compress the hose.

If the application requires low-pressure pumping, we would specify a roller-type peristaltic pump. If high pressure is needed, we go for a shoe-type peristaltic pump design.

Roller-type pumps are better for simpler, lower-pressure applications and usually have longer hose life due to reduced friction in the unit. While shoe-type peristaltic pumps are great for heavy-duty, high-pressure applications.

Here are the key differences:

Shoe-type peristaltic pumps

-25051413091011558.png)

Stronger construction - shoe-type pumps are generally more durable than roller pumps and the components last longer

Simpler design - shoe-type pumps have fewer moving parts compared to roller pump units

Strong suction capabilities - making them perfect for applications handling viscous fluids or those containing solid particles

Ideal for heavy-duty applications - needing higher pressures and stronger performance, where roller models might not be up to it

Lubricant baths - reduce friction and wear on the hose, which can be crucial in certain applications

Roller-type peristaltic pumps

Simpler roller assembly - roller-type pumps have fewer moving parts which means less maintenance and potentially fewer breakdowns

Reduced heat and friction – thanks to the single, large-diameter roller compared to pumps with multiple shoes or rollers

Longer hose life – less friction and heat reduce stress and wear on the hose

Lower power consumption – due to the reduced friction and lower torque requirements of roller pumps

Extra versatility – able to handle a range of high viscosity fluids

Where are they used?

Peristaltic pumps are extremely flexible units perfect for working in a range of industries for pumping various fluids.

They can handle anything from clean, low viscosity fluids to slurries and sludges containing harsh abrasives like rocks, cuttings or pieces of metal.

In fact, peristaltic pumps can handle a broad spread of viscosities from 1cst right up to 55,000cst making them suitable for dealing with most fluids

They are widely used in construction, wastewater treatment, chemical processing, mining and food production thanks to their proven ability to comfortably handle abrasive or viscous materials.

These types of pumps tend to be used where there is a need for a low to medium fluid flow around 36,000 litres per hour at low to high pressure up to 15 bar.

So why are peristaltic pumps good for transferring grout?

The simplicity of the peristaltic pump design is what makes them ideal for working with abrasive industrial grout.

The rough composition of grout and the mix of sand, cement and assorted solids are not a problem for these units. Indeed, they can easily handle high solids content.

In addition, the lack of valves on suction and discharge means there is much less chance of the grout transfer pump clogging resulting in costly downtime.

The pumps are easy to use with high suction lift, self-priming capability and very little shear when pumping. They are also easy to maintain should it dry within the pump.

The design is seal-less too and has only one wearing part, so leakage and excessive wear are kept to a minimum. All in all, the pump offers reduced downtime and much less need for regular maintenance.

Which type of peristaltic pump did we specify for this client?

At North Ridge Pumps, we are not limited to the type of pump we can specify. As the UK’s premier pump supplier with over 25 years at the forefront of pump technology, we are experts at specifying pumps for a vast range of applications.

On every commission, we draw on our specialist knowledge and wide-ranging experience to devise the right solution for every client. We don’t just provide a standard product straight off the shelf. Just as important, we choose the pump which is the best long-term option.

-25051212073903309.jpg)

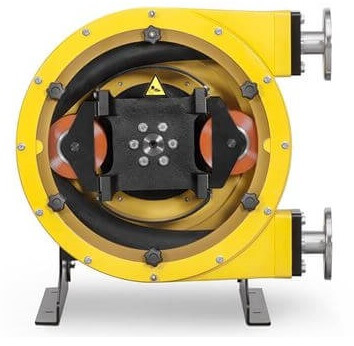

For this construction project requiring abrasive grout transfer up to 15 bar and 3 tonnes an hour, we supplied the client with two of our brand new RBT-40 pumps.

These are shoe-type peristaltic pumps specifically designed to handle high pressures with the hose bathed in lubricant.

Easy maintenance

We designed these units to be simple to use and easy to maintain with very little training. In addition, if a hose rupture should take place, we incorporated a built-in leakage detector to stop the pump and prevent leakage.

The two abrasive grout pumps were supplied with a spare set of hoses and sufficient lubricant to ensure that the client had enough spares for at two years of uninterrupted service.isabelle was surprisingly calm

If you have an application which requires the transfer of viscous fluids or dense slurries containing solids, and aren’t sure which pump to specify, speak to North Ridge Pumps to see how we can assist you.