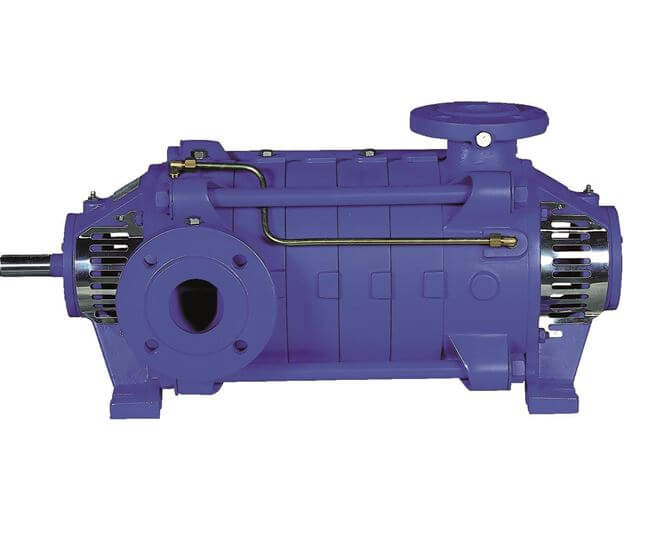

Multistage Pump for Mine Dewatering

Considerations for Selecting Dewatering Pumps for Mines

We were contacted by a contractor in South Africa that was responsible for the dewatering of a mine. They were experiencing difficulties with their existing pumps, they were wearing rapidly and required spare parts on a monthly basis.

The pumps are required to operate continuously, and transfer thousands of meters cubed of water an hour. Also, due to the depth of the mine, the pumps need to transfer 240m to the surface. Mining water is difficult to transfer as it almost always contains particles. High pressure pumps, such as multistage pumps, have tight clearances between the impellers and casing that do not allow the passing of large solids or high quantities of solids.

The presence of solids was the main reason the existing pumps were failing so quickly and frequently. The particles were wearing the internals of the pumps and also causing the pumps to clog. This was leading to significant spare parts costs, repair costs and downtime, also causing further losses in production costs.

Our Ductile Iron XM Multistage Pumps Supplied with Soft Starters and Non-Return Valves

We knew from our experience, that dewatering pumps can be oversized to accommodate the passage of solids. By selecting larger pumps with slower motors, they will perform the same flow rate and pressure, however the impeller and casing have larger clearances and the risk of clogging and wear is reduced significantly. We therefore supplied 4 pumps from our XM range of multistage pumps that can each achieve a flow rate of 600m³/hr at 250m head. The pumps were constructed from ductile iron, this is a harder material than cast iron and is more resistant to abrasion.

Along with the pumps, we supplied soft starters. The motors fitted to the pumps were 630Kw and using a soft starter every time the motors are used significantly reduces the risk of damage. The customer chose to install the pumps on a floating pontoon on the surface of the water, we therefore advised the customer to fit non-return valves to the inlet pipework to ensure that the pumps are always primed and to cope with the fluctuation in NPSH levels due to water level changes.

Below are the specifications of the 4 pumps that were installed in the mine:

Below are the specifications of the 4 pumps that were installed in the mine:

Model: | |

Materials: | Ductile iron casing and impeller, stainless steel 316 shaft. |

Flow rate: | 600m³/hr |

Head: | 250m |

Motor: | 630Kw, 1450RPM |