What Are Vertical Immersion Pumps?

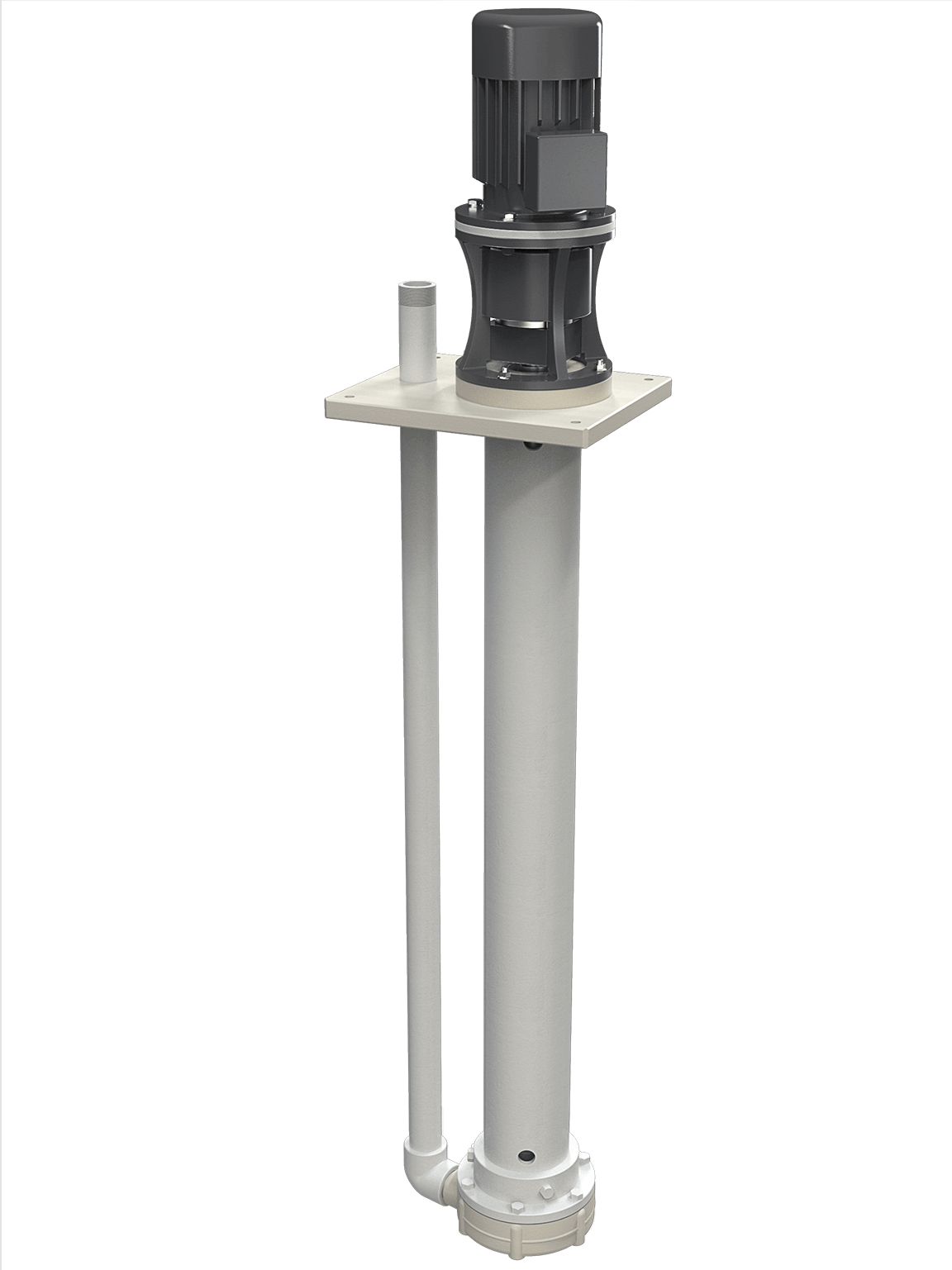

Vertical immersion pumps (also known as vertical column and shaft pumps) are a design whereby the motor is separated from the fluid being pumped. Typically used in tanks or pits in place of pumps which require flooded suction or priming.

Vertical immersion pumps are available in two types as an immersion or Cantilever pump -with or without bearing support.

A cantilever pump has an extended motor shaft meaning the maximum length of the vertical column is limited to just under 2M. An immersion pump has a separate shaft driving working parts enabling it to be manufactured to longer lengths up to 100M.

A bearing support reduces the radial forces preventing the unit from “whipping” which is the result of having a rotating force at the end of a shaft.

An immersion pump can be manufactured with a single-stage impeller for low pressure and high flow applications, but also with a multistage immersion head design for high pressures and low flow designs. At long lengths when it is not possible to have an immersion or self-priming pump submersible pumps are utilised for applications such as oil rig water supplyThier

At long lengths when it is not possible to have an immersion or self-priming pump submersible pumps are utilised for applications such as oil rig water supplyThier

Their design is similar to an end suction centrifugal pump connected at the end of a column. An impeller is housed in the submerged casing, driven by the shaft within the column. A motor is connected at the top outside of the fluid which can be on a base plate sized to cover the pit. Discharge connections can be at a 90° angle to the suction port at the bottom of the column, or alternatively be mounted on the mounting plate for ease of connection during installation. High pressure pump designs utilise a multistage pump design, which contains several impellers enabling clean fluids to be transferred at low to medium flows.

Vertical immersion units have several benefits over submersible pumps which include:

· Higher temperature fluids can be transferred

As the pumps are immersed in the liquid, with the absence of seals which are often most vulnerable to high temperature degradation. This enables liquids of several hundred degrees to be transferred where self-priming pumps or submersible pumps can not be utilised.

Vertical centrifugal immersion pumps are the ideal solution where there is a cavitation risk. When high temperature liquids close to their boiling point are being transferred, there is often a very narrow margin of NPSH Available.

This can often mean a self-priming pump is not suitable particularly when which during its lifespan in the application the pump will experience a loss of efficiency potentially leading to cavitation. A pumps NPSH required can increase by 50% due to a doubling of wear ring clearances. This means the only viable option is a sump pump.

· Enables flammable liquids to be transferred

Submersible pumps are no longer advised as being suitable for the transfer of fuels or other flammable liquids. Immersed pumps mean the liquid is kept separate from the motor.

If submersible pumps are used and seals on the motor wear or degrade it poses a risk of explosion. Manufacturers of oils and fuels often change fuel blends through the addition of additives, which can cause previously thought sound seals to degrade.

· Longer maintenance intervals as the motor is not immersed in a fluid

Submersible pumps require periodic checks for signs of wear, should be monitored and typically operate in duty/standby mode in critical applications. Often the first sign of a submersible pump requiring maintenance is its failure in duty as it is located out of sight and out of mind. As motors of immersion pumps are outside the fluid, they are more durable, and less susceptible to seal failure.

· Individual components can have specific materials specified for longevity and chemical compatibility.

Immersed pumps can have individual components specified for applications, and longevity rather than acceptance of a standard manufacturers materials as is common with submersible pumps. Parts can be specified for chemicals in materials such as polypropylene, or PVDF to Stainless Steels, hastelloys or duplex Stainless steel not possible with submersible pumps. In high purity applications pumps can be manufactured in a single material eliminating the possibility of cross contamination with metals for example in plating applications and with plastics with purified water.

· Confined space entry not required

Vertical sump pumps do not require entrance to a pit for maintenance and are usually removed from service for maintenance via a crane or hoist. Submersible pumps require entry into confined spaces for installation and at times for maintenance thereby increasing the risk and associated cost of maintenance.

These types of equipment are used in place of Self Priming pumps which may not be practical for selection due to large suction depths, viscous fluids, volatile fluids and high temperatures.

Vertical Centrifugal Immersion Pump Design | Cantilever Pump Design | Cantilever Pump with bearing support Design |

Separate Shaft to motor shaft meaning motor shaft, and bearings do not bear the full load of pump. Also means components can be replaced individually rather than complete unit | Some shorter designs have no bearing support in pump which means reliance is on motor bearings. The pump components including column and impeller are solely supported by the motor. Heavy duty industrial designs such as the XIW have a secondary set of bearings in a housing above the plate | Shafts are given extra support through utilisation of additional bearings however care must be taken to ensure pure and solid laden liquids do not cause damage to the pump bearings |

Bearings and seals are located outside of the liquid | Bearings and components are located outside the fluid preventing possible contamination of vital components | Bearings and components are located outside the fluid preventing possible contamination of vital components |

Pumps can be constructed which can be up to 100M long | Pump shaft is of a larger diameter and more durable | |

May have additional cooling and lubrication requirements | Suited for abrasive and solid laden liquids | |

Enables various pump designs to be utilised from single stage impellers to multistage designs for higher pressures | Due to the absence of components in the liquid this design is used in high purity applications such as pharmaceutical and plating as only a single type of metal is in contact with the liquid. | |

Seal is outside of liquid | ||

|  |  |

Which applications are a vertical sump pump best used for?

Tank emptying – as the pump is immersed in the tank the pump can be used to empty tanks, with models selected to completely empty tanks, or be positioned slightly above the bottom of the tank meaning sludge and debris are not introduced into pumping processes.

High temperature fluid transfer – As mentioned above, sump pumps are able to handle fluids of several hundred degrees, and also cope with low NPSH requirements.

Fuel Transfer - As electrical components are separate to mechanical fuel transfer is not an issue

Low NPSH Available - With the pump immersed in liquids, NPSH is not normally an issue.

Long suction lines – if large amounts of air require evacuating from long suction lines, the change to an immersed pumps can mean reduced priming times.

Plating Applications – non metallic materials can be selected.

What Impeller types are available with vertical immersion pumps?

Impeller types range from standard closed impeller for high efficiency of clean fluids, to open impellers for solid handling with up to 85% efficiency or non clog for the handling of sludges, sewage or abrasive matter in suspension of the liquid.

Can Sump pumps be ran dry?

It is possible to have dry run designs of sump pump which include a lubricated shaft either by oil, or glycols. This keeps the shaft and seal cool enabling the pump to operate without fluid. However the fluid must be monitored to ensure it remains at specified levels.

See our P&ID Symbols for Sump Pumps or Vertical Turbine Pumps

View our range of Vertically Immersed Pumps or contact us for a selection to be made according to your requirements.