What are Industrial Hose Reels

What are Industrial hose reels?

Industrial hose reels allow the practical and efficient management of hose used to dispense fluids in multiple areas across a range of distances with ease.

When to use?

Utilising hose reels ensures damage is prevented to hose, it does not cause a tripping hazard, and kept in organized fashion.

Hose reels can be used for a variety of gasses and liquids including:

Oil

Water

Air

Grease

Diesel

Adblue

LPG Methane

How to Select

In order to select a hose reel the following is required to ensure the correct material of hose, length and pressure rating is set. Reels are limited according to the length and diameter of the hose they house.

Fluid

Flowrate

Length of hose

Diameter of hose

Fluid pressure

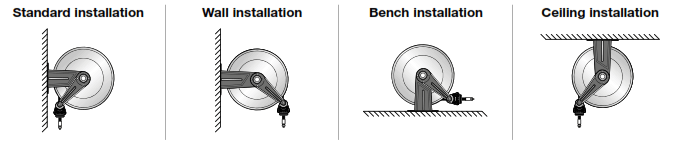

Where to mount

As units are used for liquid dispensing across a range of industries, they are designed to be mounted in a number of ways including:

Ceiling

Floor

Bench

Vehicle Mounted

Wall

Features:

Units can incorporate a variety of features including

Automatic stop - When tube is pulled to the required length, the hose reel will automatically stop rather than auto rewind

Swivel / Fixed- Models can be fixed bracket design or swivel enabling the unit to rotate laterally (up to 55° in either direction) increasing flexibility for process

Encased or Open – Models can be encased within a housing protecting hose from the elements, within dusty atmospheres.

Retractable – Automatic rewind models are available for small diameters of tube, however as hoses become of larger diameter, containing more fluid conventional unpowered rewind mechanisms are unable to retract the hose.

At this point a Manual, electric, air powered or hydraulic powered model must be chosen to rewind the hose.

Materials – Units can range in construction from ABS (plastic), to Painted Steel or Stainless Steel depending on installed location, corrosiveness of atmosphere, hygiene/washdown required and whether the reels are installed within an ATEX Environment.

Certification – Reels can be ATEX certified, with conductive hose or food grade for hygienic applications

Accessories

Some accessories which may be worth considering when selecting a model include:

Mounting Bracket – To enable the reel to be mounted in the location required

Hose Fittings – When the model is connected to process, fittings may be required to connect the unit to pumps, lances and trigger nozzles

Grounding Reel – If a reel is transferring flammable liquids a grounding reel may be required to ensure if there is a build up of static it can be discharged safely.

Leakage Detector – Hose reels and pumps are typically kept under pressure and not disconnected from supply to ensure they are always available for convenient use. A leakage detector ensures if a leak forms the unit will be stopped if this occurs out of office hours.

If you are looking for help in selecting a suitable model for your process, contact us on 01773 302 660 or email [email protected]