What are Inline Basket Strainers?

What are Inline Basket Strainers?

Basket strainers are a device typically connected to a pumps suction, which is used to filter out solids or debris larger than the mesh contained within the strainer, which would otherwise damage the pump, internal parts or system. They are used to capture particles which are usually visible to the naked eye, and if smaller, filters are typically used.

Strainer Vs Filter | |

Used to capture larger solids visible to naked eye | Used to capture particles invisible to naked eye <40 microns which may include salts, or carbon particles |

Designed for a single type of fluid | Can capture different fluids such as water within oil |

Lower pressure drop enabling use of low pressure designs of pumps | Require high pressure pumping involving high powered positive displacement or multistage pumps which if selected incorrectly will experience rapid wear by the handling of such particles |

Filter mesh is designed to be reused over many years | Can be single use or reused through the use of backwashing |

Working Principle of Strainers

Designs consist of a suction inlet, discharge outlet, bolted top cover and casing. The casing holds a filter typically manufactured from wire mesh designed to filter solids which become trapped by the mesh, and sink within the casing. Top covers can be clear or solid. Housings may have a drain at the bottom of the casing where solids will sink to enable them to be drained away.

Basket Strainer Designs

There are various designs known as Y Type, Simplex, Duplex or Backwash.

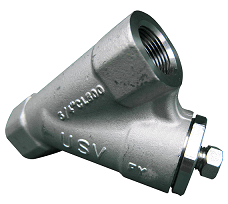

What is a Y Type Strainer?

This type of design is the most economical type which can be mounted horizontally or vertically and is compact in design. Other designs can typically only work horizontally.

They are cast in one piece, meaning they usually have a higher pressure rating tolerance. However due to their design, they produce a larger pressure drop than other variants.

What is a Simplex Strainer?

Simplex models are designed for larger pipework, are longer and wider in design containing a significantly larger basket with removable lid for ease of maintenance.

Due to the larger surface area they are designed for capturing larger amounts of solids, and produce lower pressure drops. They can only be installed horizontally, but are easy to inspect and maintain without drainage of pipework.

What is a Duplex Strainer?

Duplex models are very similar to simplex strainers in design, however contain two filter baskets which can operate simultaneously or separately. Having twin filters ensures processes can run interrupted whilst they are maintained, as one can continue to function, while the other is maintained.

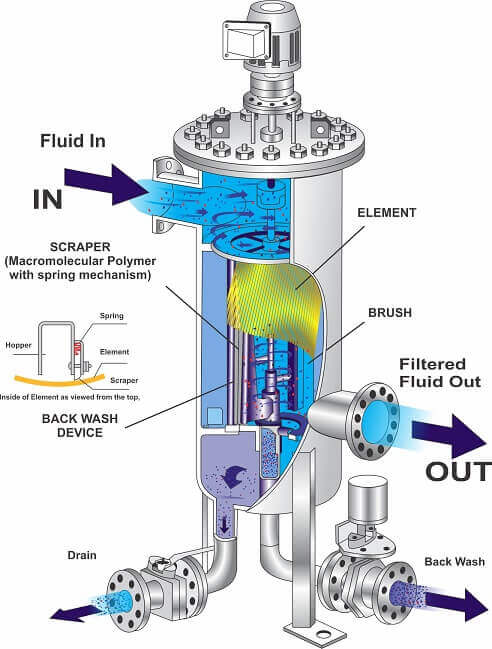

Self Cleaning Strainer/Backwash / Automatic Strainer Design

Self cleaning strainers, also known as backwash filters or automatic strainers consist of a strainer, drain, scraper and motor.

Within the strainer there is a hollow shaft with a blade which when the cleaning process is initiated, scrapes along the inside of the mesh removing debris. Simultaneously a bottom outlet valve opens creating an area of low pressure causing the recently freed debris to flow via the bottom outlet valve and be drained away.

The cleaning process is initiated either by a timer, which starts the motor located at the top of the unit to begin the screening process or via a differential pressure switch which senses when the screen is blocked.

Pressure switches are located on the inlet and outlet of the unit and when the inlet pressure is higher than the outlet pressure, the filter is known to be blocked.

These are low maintenance designs enabling the mesh to remain clean and free from solids with long maintenance intervals, without manual intervention.

Strainer Design Comparison Table - Basket Simplex strainer vs Duplex vs Y Type

Y Type | Simplex Strainer | Duplex Strainer | Backwash / Auto cleaning |

Mounted Horizontally or Vertically | Maintain without draining pipework | Mesh can be cleaned without Process Stoppage | Autonomous self-cleaning |

Compact in design | Lower Pressure Drop | Redundancy / Spare Capacity in Design | Zero process stoppage |

Economical | Higher Solids Capture | ||

Disadvantages | |||

During Cleaning as the strainer is at the lowest point, there is a larger loss of fluid and system may need to be drained | Process must be stopped during cleaning | Bulkier in Design | Large units requiring piping to drain, which may require secondary filtration or dewatering

|

Higher Pressure Loss | Only Work Horizontally | Only Work Horizontally | Higher Initial Outlay |

Pressure Loss

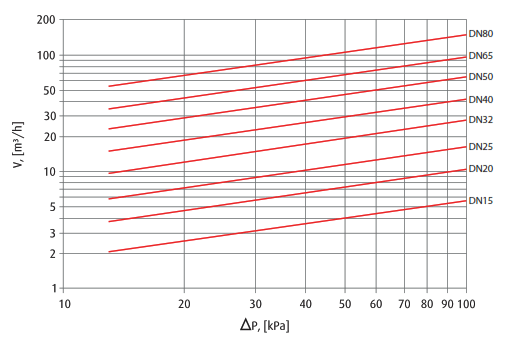

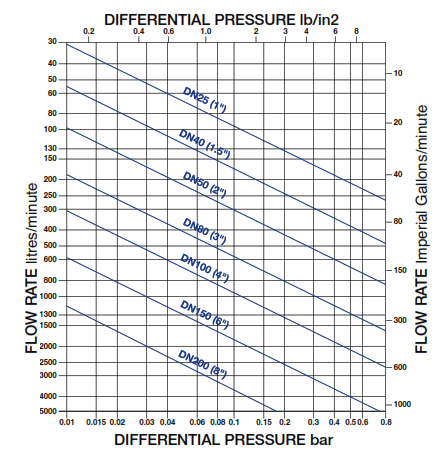

Below is a graph indicating single and double Basket strainer Pressure drop compared with Y type designs:

At a flow of 10M³H, (166L/min) the pressure drop on the basket type is only 0.3 bar, compared with 0.4bar (40KPA) for a 1" (DN25) Type

Single Basket vs Y Type Pressure Drop

Accessories

Pressure Differential Indicator - This measures the pressure within the unit and when calibrated can detect high casing pressure, or higher inlet pressure signifying that the strainer mesh is blocked and requires cleaning.

Heating Jackets / Insulation Jackets – If material being filtered has a viscosity which changes with temperature then a heating jacket may be required to prevent solidification within the unit. Similarly, if strainers are subject to excessive heat from process such as within a steam process then an insulation jacket maybe required to ensure heat stress is not experienced by the unit unequally during operation.

Magnetic Filters – These are used to capture fine metal particles which may be present within the liquid and so fine they are unable to be detected by metal detectors. They are captured by magnets, and used within the food industry to ensure hygiene, and in the paint industry to prevent the formation of black specks within paint.

Air Eliminator – Typically designed to sense air and remove before liquid flows through a flow meter to ensure accuracy in a process or prevent issues further downstream of process.