Pump specification and design

Pumps designed and developed for your particular application and offering the lowest lifetime cost

Industrial processes can be inherently risky. Whether your transfer process includes corrosive or poisonous fluids, flammable liquids or those that present extreme temperatures, you need to ensure that the risk to your workforce has been properly assessed and mitigated.

Pumps can play a vital role in ensuring worker safety by removing unnecessary handing, minimising the risk of spillages and leaks, and can keep flammable liquids away from mechanisms within your process that may ignite the fluid.

We can help you assess your process and offer a solution that will keep your employees safe, as well as being robust and cost effective for your business.

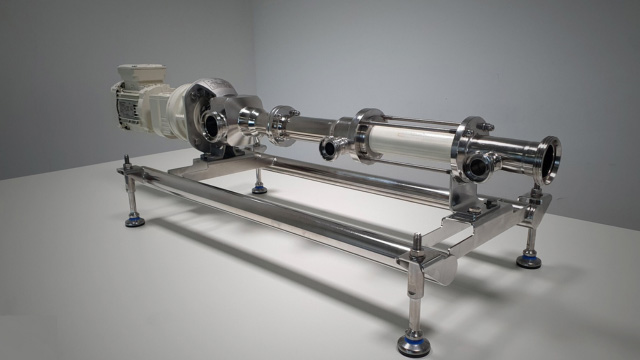

Pump kits can be designed to eliminate manual handling of dangerous liquids which may be hot, flammable, corrosive or dangerous. Kits also enable easy porting between processes ensuring less strain is felt by operatives in repetitive processes.

Pumps transfer hazardous liquids such as chemicals and fuels. By automating transport, pumps can minimise worker exposure to these dangers. Utilising seal less designs further ensures there is zero chance of leakage and interaction with liquids transferred.

Pumps can be used in automated cleaning systems, eliminating the need for workers to manually handle hazardous cleaning agents or enter confined spaces. They also ensure cleaning is to the same high standard every time.

Safety is paramount in some processes. Incorrect dosing can lead to dangerous chemical reactions, exposing workers or the end user to toxic substances, or causing explosions. Implementing reliable metering systems, using advanced technology like flow meters and automated dosing pumps, and regular calibration are essential practices for many industries.

Whether your requirements are for ATEX pumps in flammable environments or hygienic rated for guaranteeing safety and limiting the potential for bacterial growth.

We provide a complete pump specification, design and replacement service covering a range of processes and almost any fluid.

Pumps designed and developed for your particular application and offering the lowest lifetime cost

Specification of new pumps to replace units at the end of their working life

Diagnosing and eliminating operational issues

Lower maintenance and running costs caused by clogging, seal wear or repeated failure

Better performance and more streamlined process efficiency

Less risk by eliminating manual handling and automated fluid transfer

More InfoNo more inaccurate transfer of costly ingredients ensures more consistent results

Easy-to-clean pumps can be quickly and effectively sanitised to comply with the highest standards

Maximise high viscosity fluid transfer from containers

Through reduced power consumption and increased process efficiency

© North Ridge Pumps 2025

Registered Business Address: 12 Bridgford Road, West Bridgford, Nottinghamshire NG2 6AB - Registered in England & Wales 03652700

Privacy Policy / Cookie Policy / Terms & Conditions / Resources / Pump Repair / About Us / Contact